A whole machine intelligent testing method and system for a power system protection device

A technology for power system protection and testing methods, which is applied in the directions of measuring devices, measuring electricity, measuring electrical variables, etc., can solve the problems of a large proportion of manual testing links, low testing efficiency, and many device power-on times, so as to improve the overall performance of the machine. Test efficiency, reduce test labor intensity, improve test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

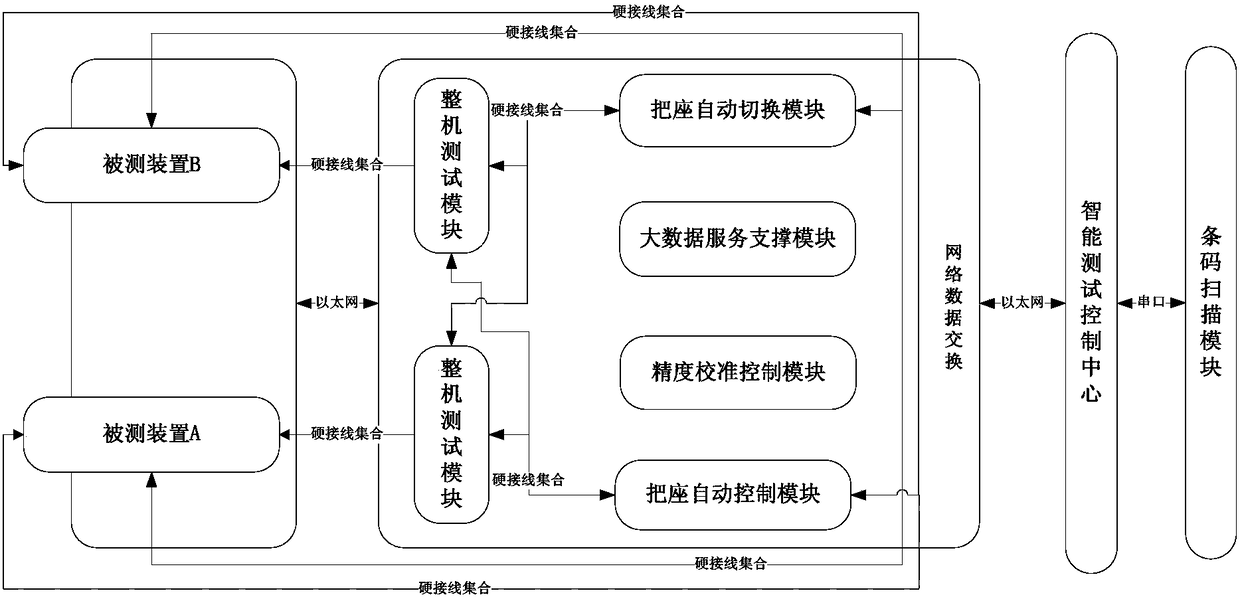

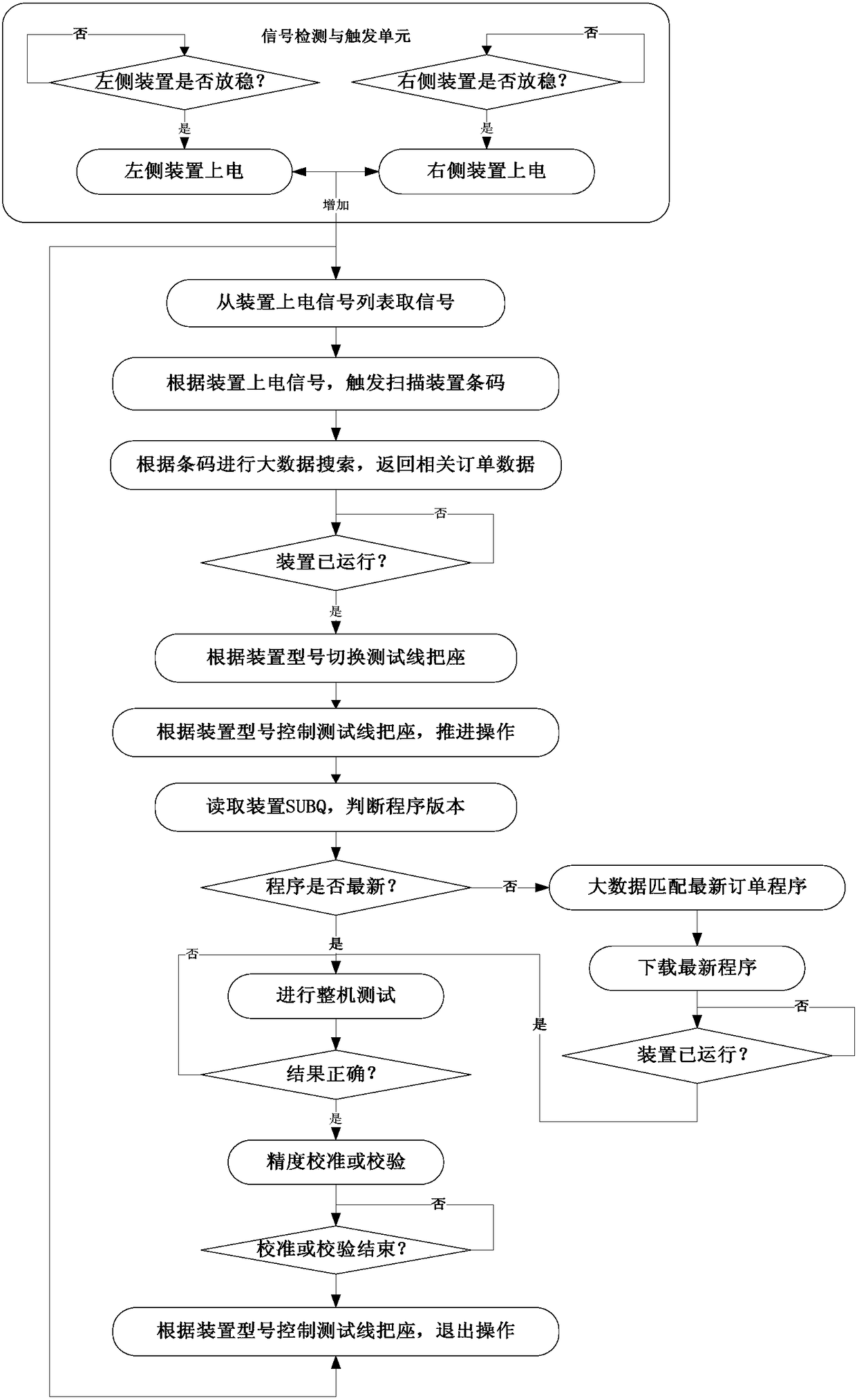

[0035] The invention provides a whole machine intelligent testing method and system for a power system protection device. This method triggers the barcode scanning device by sensing whether the device is stable. According to the barcode of the device, the corresponding order information of the device is obtained through the big data service support module, and the original order data of the device is obtained. According to the original order data of the device, through the handle switch module and the handle control module, the power-on of the device and the switch-on and switch of the handle of the test line are automatically completed, so as to complete the connection between the device test contact and the test board contact of the whole machine, and realize protection Closed-loop testing of the device. After the test of the whole machine is completed, the analog quantity is automatically controlled for output, the accuracy of the device is automatically calibrated and sti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com