Ultra-high frequency partial discharge sensor performance test tool and device based on GTEM cell

A partial discharge and testing tooling technology, applied in the direction of measuring devices, testing dielectric strength, instruments, etc., can solve problems such as unfavorable sensor performance verification, evaluation and comparative analysis, low test result accuracy, and poor test result consistency. , to improve the detection level and reliability, solve the poor consistency of results, and eliminate uncertain factors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

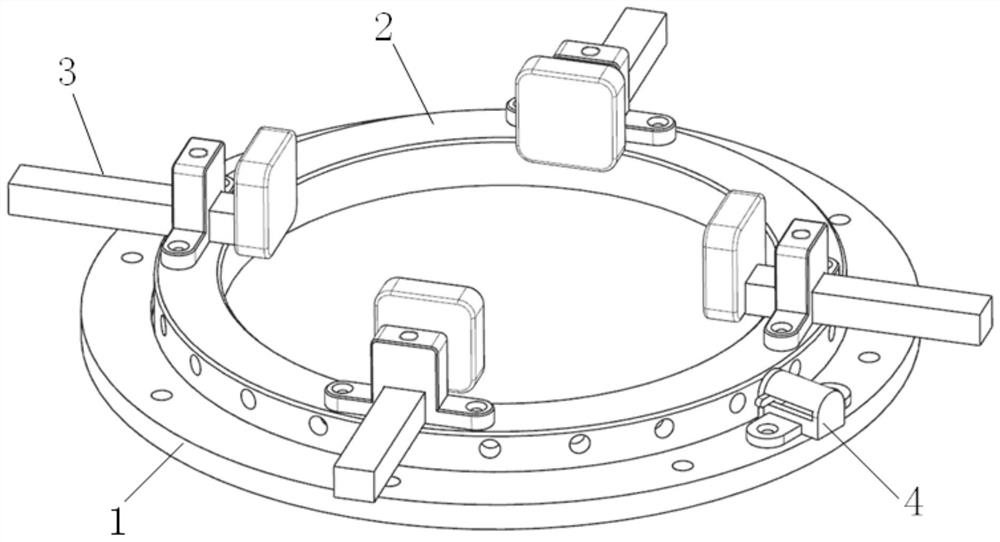

[0035] Such as image 3 As shown, this embodiment provides a GTEM cell-based UHF partial discharge sensor performance test tooling, including a fixed ring 1, a flange 2, a clamping assembly 3, and an angle adjustment assembly 4. The flange 2 is installed on a fixed The inner ring of the ring 1 can rotate circumferentially along the inner ring of the fixed ring 1. The clamping components 3 are set in multiple groups and are evenly distributed on the edge of the flange 2 along the circumferential direction. The clamping components 3 are clamps with adjustable radial distances. When installing the sensor, multiple sets of clamping components 3 are in contact with the side of the sensor and clamped. The angle adjustment component 4 is arranged on the flange 2 and the fixing ring 1. The angle adjustment component 4 is used to adjust the relative The rotation angle of the ring 1 is fixed and the position of the flange 2 is fixed. In this embodiment, four sets of clamping assemblies ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com