Position measuring system for heading machine cutting head

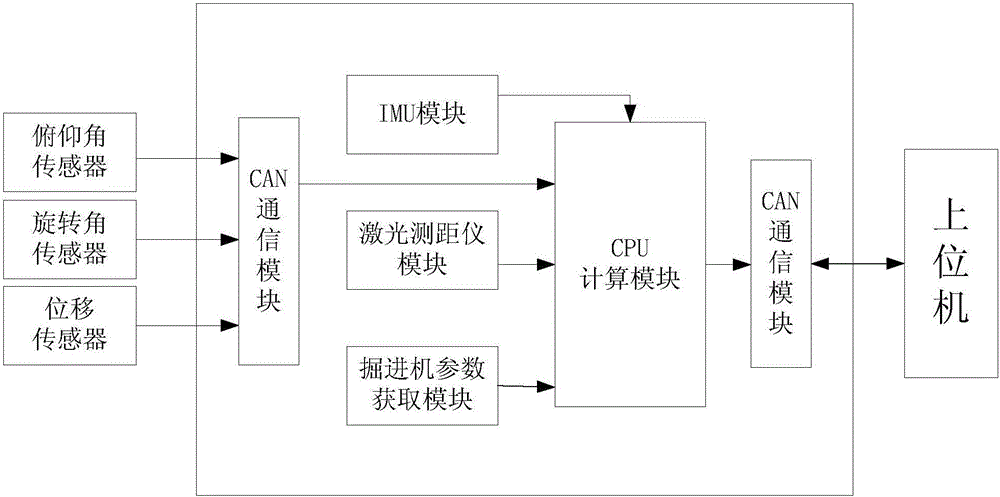

A measurement system and technology for roadheaders, which are applied to measurement devices, navigation through speed/acceleration measurement, mapping and navigation, etc., can solve problems such as inaccurate excavation, harsh environment, and line of sight affecting excavation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

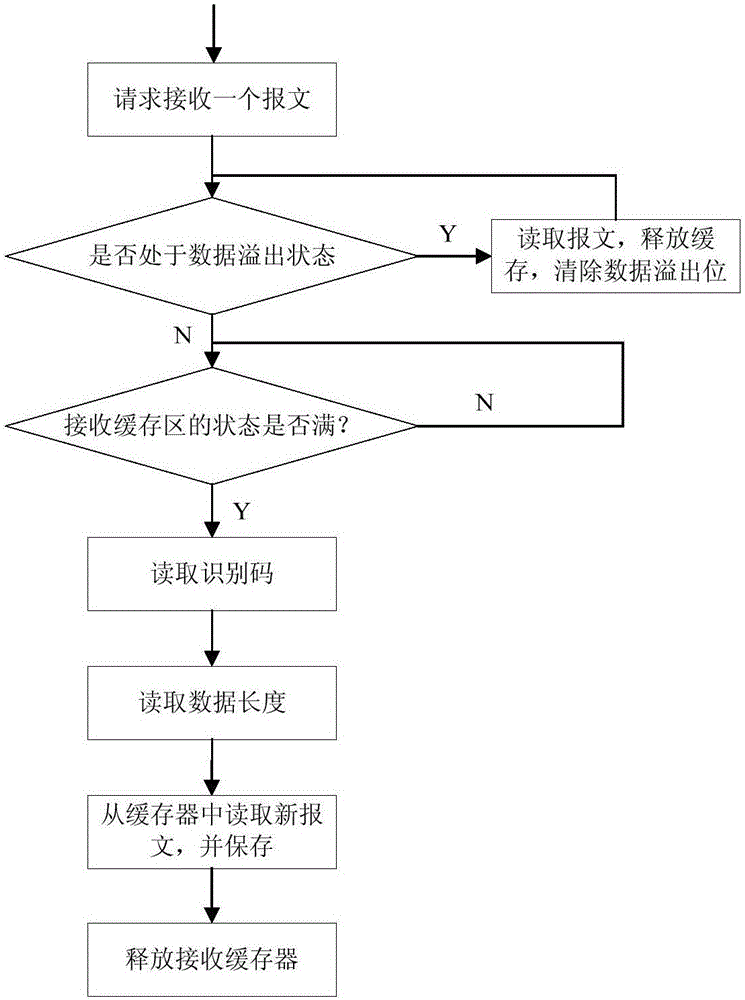

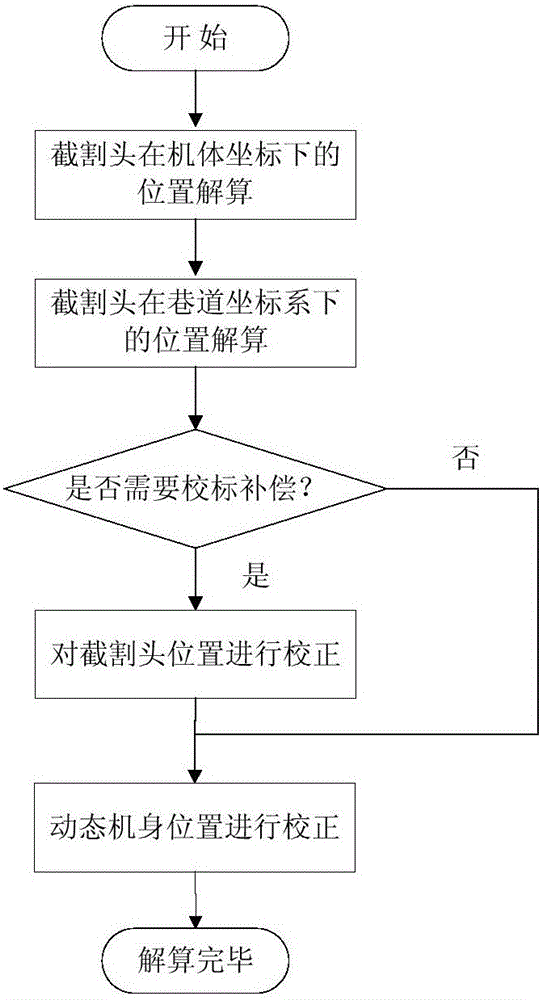

Method used

Image

Examples

Embodiment 1

[0124] Place the pitch joint at 5.0°, rotate the cutting arm from right to left, and measure the position information of the cutting head at different rotation angles. The results are as follows:

[0125] Table 2 Rotation measurement data of rotary joint 1

[0126]

[0127]

Embodiment 2

[0129] Place the rotary joint at 14.0°, lift the cutting arm from bottom to top, and measure the position information of the cutting head at different pitch angles. The results are as follows:

[0130] Table 3 Pitch joint rotation measurement data 1

[0131]

Embodiment 3

[0133] Move the fuselage forward for a certain distance, place the swivel joint and pitch joint at any angle, and select 10 random positions to measure the position information of the cutting head. The results are as follows:

[0134] Table 4 Measurement data of fuselage moving forward for a certain distance

[0135]

[0136] It can be seen from the above data that the errors in the X direction and the Z direction are all within 100 mm, which proves that the present invention can obtain high-precision measurement results under both static and dynamic conditions, and verifies the feasibility and advantages of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com