A kind of wide area asphalt and preparation method thereof

A kind of asphalt and wide-area technology, which is applied in the field of wide-area asphalt and its preparation, can solve the shortage of wide-area asphalt raw materials and other problems, achieve excellent high temperature stability, high penetration index, and change the effect of temperature sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

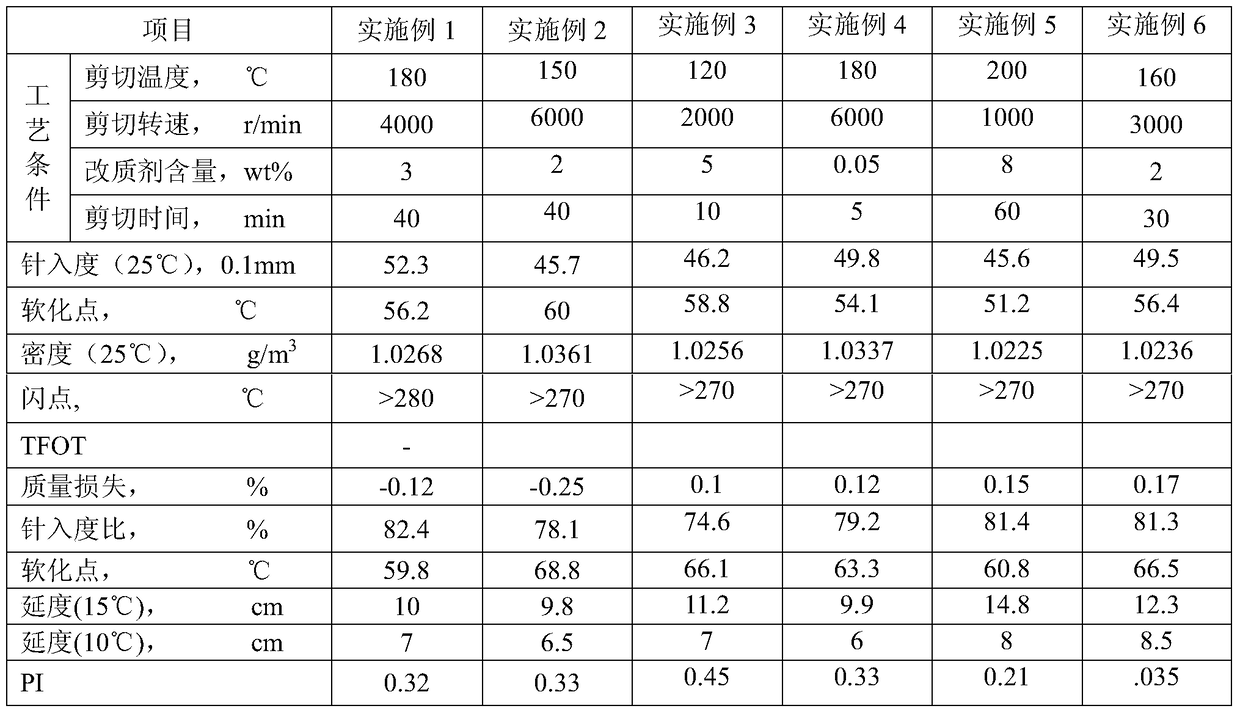

Embodiment 1

[0060] The vacuum residue of 97wt% atmospheric and vacuum equipment was heated at 180°C for 1.5 hours to make it into a fluid state; then 3wt% calcium oxide was added to the flowing soft asphalt, and the reaction temperature was controlled to be 180°C. High-speed shearing at a speed of 4000 rpm for 40 minutes; the prepared asphalt sample was kept at a temperature of 160°C for 1 hour to obtain a wide-area asphalt product. Among them, the properties of the vacuum residue raw material of the atmospheric and vacuum unit are shown in Table 1, and the properties of the obtained wide-area asphalt product are shown in Table 4.

Embodiment 2

[0062] Heat 98wt% of the vacuum residue of the atmospheric and vacuum unit at 150°C for 3 hours to make it flow; then add 2wt% calcium hydroxide to the flowable soft asphalt, and control the reaction temperature to 150°C , shear at a high speed of 6000 rpm for 40 minutes; keep the prepared asphalt sample at a constant temperature of 160°C for 40 minutes to obtain a wide-area asphalt product. Among them, the properties of the vacuum residue raw material of the atmospheric and vacuum unit are shown in Table 1, and the properties of the obtained wide-area asphalt product are shown in Table 4.

Embodiment 3

[0064] 95wt% real boiling point distillation device deep-drawn vacuum residue was heated at a temperature of 120°C for 1 hour to be in a fluid state; then 5wt% calcium oxide was added to the fluid vacuum residue to control the reaction temperature to 120°C, high-speed shearing at a speed of 2000 rpm for 10 minutes; keep the prepared asphalt sample at a constant temperature of 120°C for 1.5 hours to obtain a wide-area asphalt product. Among them, the properties of the vacuum residue raw material drawn from the true boiling point distillation unit are shown in Table 2, and the properties of the wide-area bitumen obtained are shown in Table 4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| penetration | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com