Film mulching aerobic composting reactor test apparatus

An aerobic composting and testing device technology, applied in fertilizing devices, applications, organic fertilizers, etc., can solve the problems of large-scale testing of engineering quantities, lack of systematic research, low efficiency, etc., and achieve improved testing efficiency, convenient operation, and airflow. Precise and smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

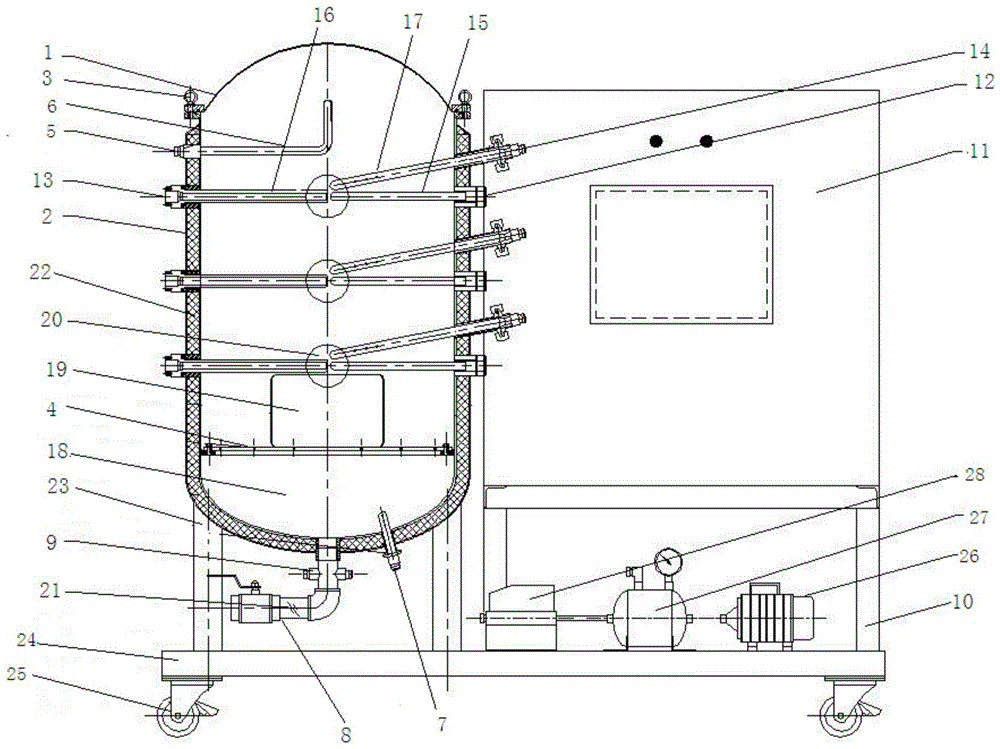

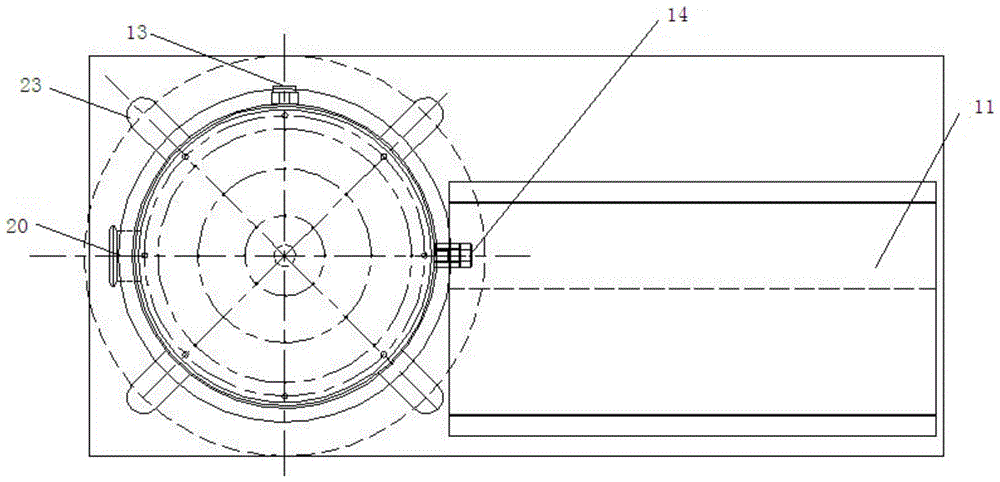

[0020] Such as figure 1 , figure 2 As shown, the present invention provides a test device for a membrane-covered aerobic composting reactor, which includes a membrane system 1, a tank body 2, bolts 3, an air distribution screen 4, a sensor group, a first pressure sensor 5, a right-angle elbow 6, A second pressure sensor 7 , a filtrate collector 8 , an air inlet 9 , an air distribution system 10 and a PLC control system 11 . A hollow stainless steel ring is set between the membrane system 1 and the top of the tank body 2, and is fixedly connected to the tank body 2 by bolts 3, which is convenient for disassembly and ensures good sealing. The lower part of the tank body 2 is provided with an air distribution screen 4 for the gas to evenly enter the stack. Located above the air distribution screen 4, three sensor groups are arranged at intervals on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com