Oil extractor for printing and dyeing water liquid

An oil absorber, printing and dyeing water technology, applied in the directions of liquid separation, textile industry wastewater treatment, grease/oily substance/float removal device, etc., can solve problems such as unsatisfactory effect and achieve good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

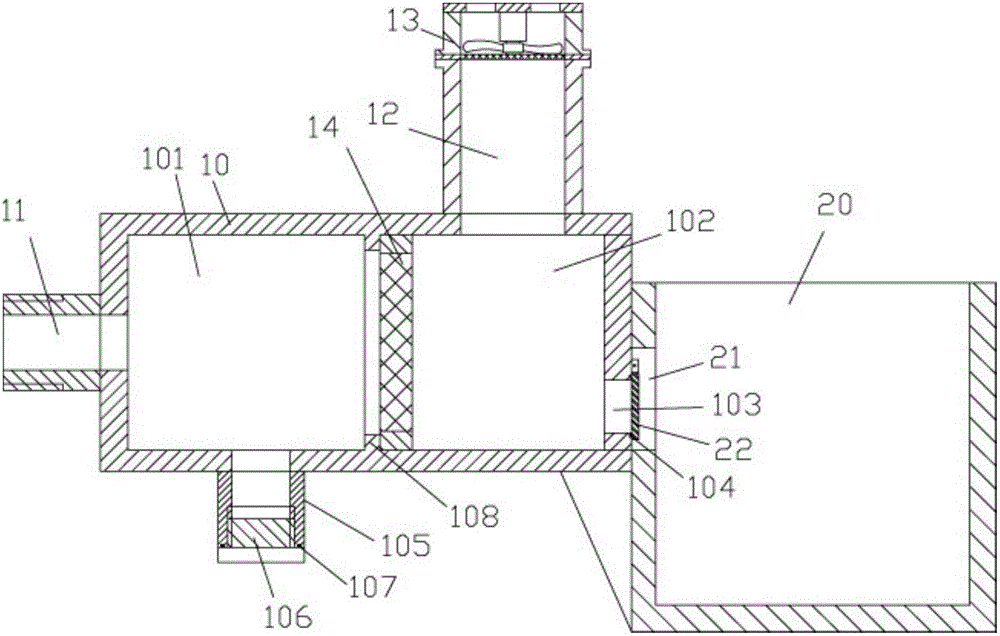

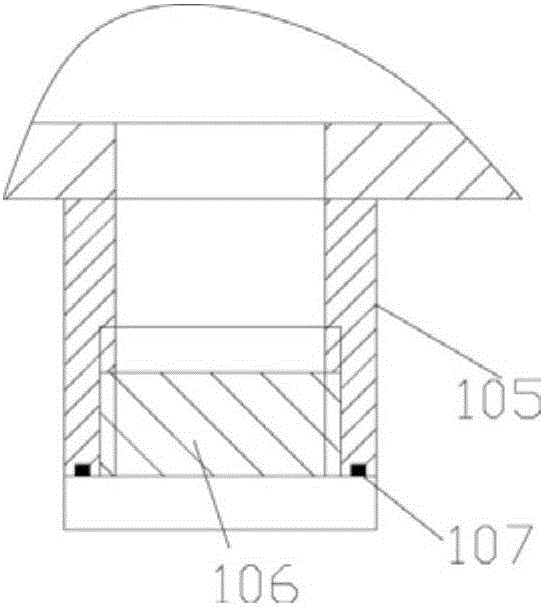

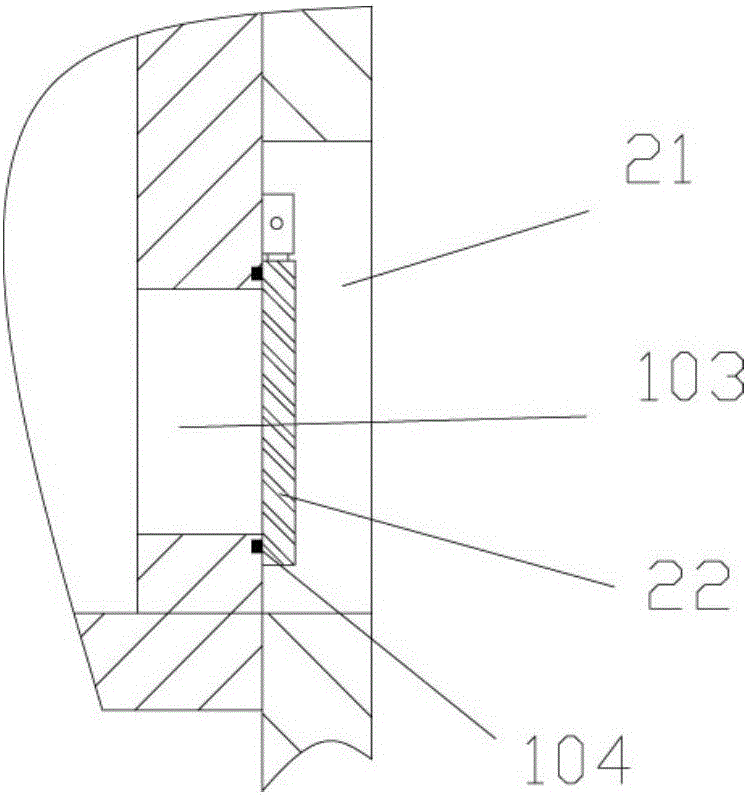

[0016] Examples, see e.g. Figure 1 to Figure 3 As shown, a printing and dyeing water-liquid oil absorber includes an oil suction box 10 and an oil storage tank 20, the left side plate of the oil suction box 10 is connected with a gas-liquid mixing inlet pipe 11, and the right side of the top plate of the oil suction box 10 is connected There is a connecting vent pipe 12, the top of the connecting vent pipe 12 is fixed with a suction fan 13, the intake end of the suction fan 13 communicates with the connecting vent pipe 12, and the middle part of the oil suction tank 10 is fixed with a filter screen plate 14, the filter screen The plate 14 separates the oil suction box 10 into a left filter cavity 101 and a right cavity 102, and connects the vent pipe 12 to communicate with the right cavity 102. The bottom of the right side plate of the oil suction box 10 has a liquid outlet through hole 103, and the right The oil storage tank 20 is fixed on the side plate, and the liquid outl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com