Combined tower crane for roof construction and construction method thereof

A construction method and technology of combined towers, which can be used in cranes and other directions, can solve problems such as inability to hoist construction by mechanical equipment and complex structures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

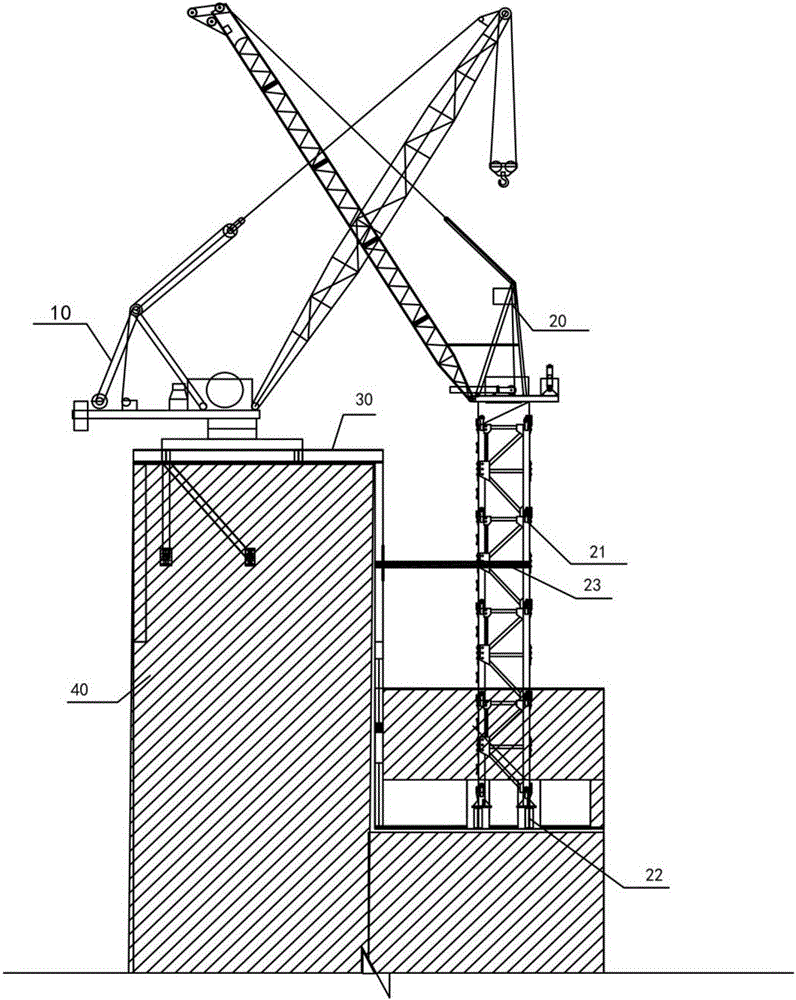

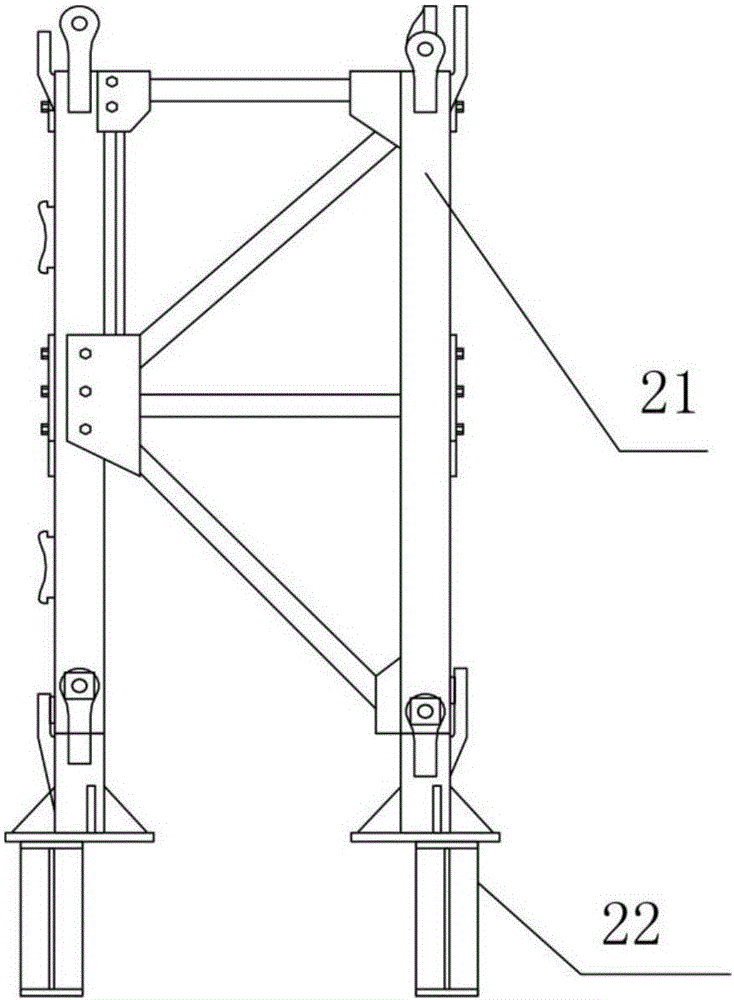

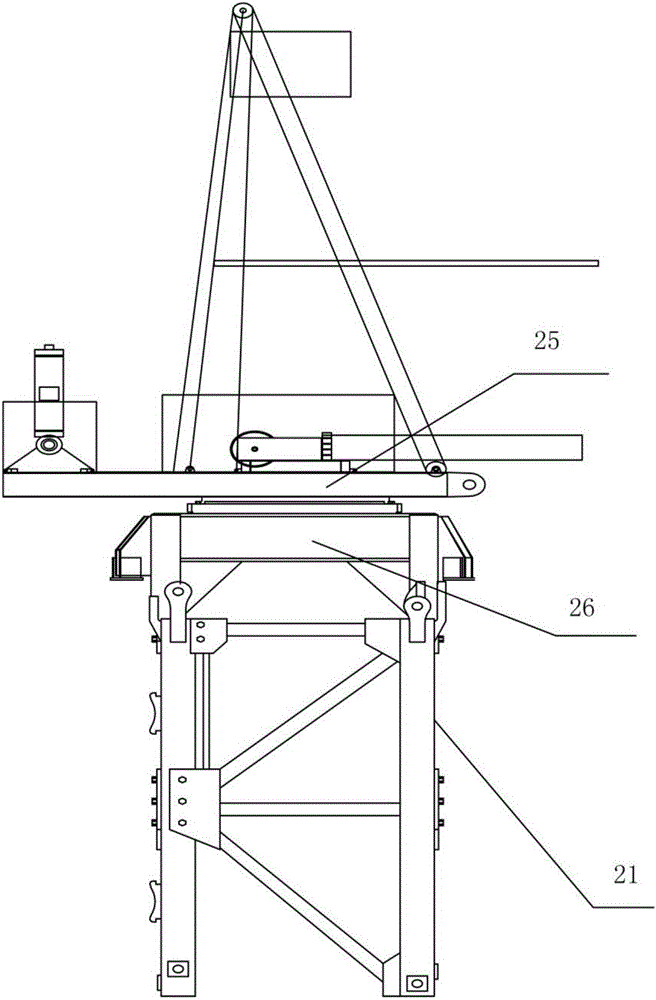

[0027] This embodiment takes a technical renovation project as an example. The height of the original tower structure of the project is kept to 115.75m. Due to the limitations of the site and the original structure, it is impossible to install external tower cranes and internal (external) climbing tower cranes. Finally, new towers are added to the periphery and roof of the tower. The steel structure is installed in place using the combined tower crane of this embodiment. Such as Figure 1 to Figure 4 As shown, a combined tower crane for roof construction includes roof crane one 10 and roof crane two 20 arranged side by side. 40 connection, the tower crane foundation includes the tower body 21 and the foundation steel beam 22, the upper end of the tower body 21 is connected with the roof crane 20 rotatably, the lower end of the tower body 21 is fixedly connected with the foundation steel beam 22, and the foundation steel beam 22 is fixedly connected with the roof 40 .

[0028...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com