Self telescopic sleeve type load bearing rail

A self-telescopic, sleeve-type technology, applied in the direction of lifting device, loading/unloading, transportation and packaging, etc., can solve the problems of low container loading and unloading efficiency, difficulty in meeting modern loading and unloading needs, limited advance and retreat of forklift operation, and achieve simplified automation The loading and unloading process, the convenience of carrying and disassembling, and the effect of improving the quality of work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

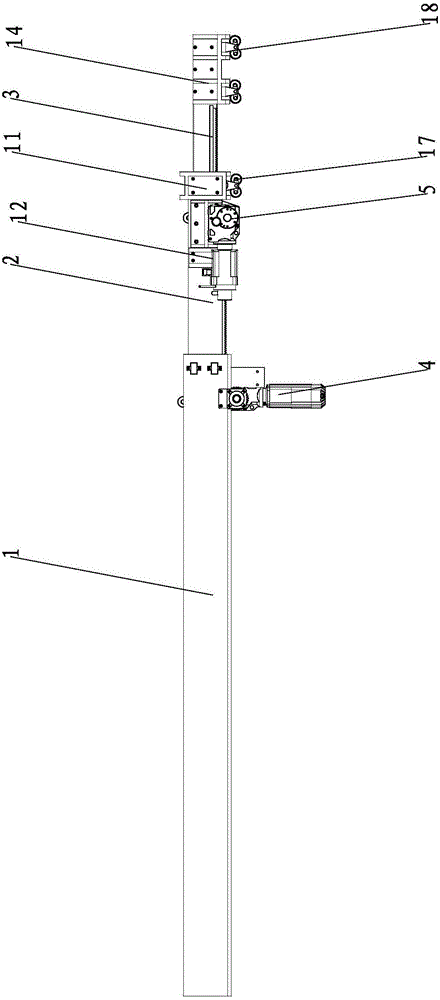

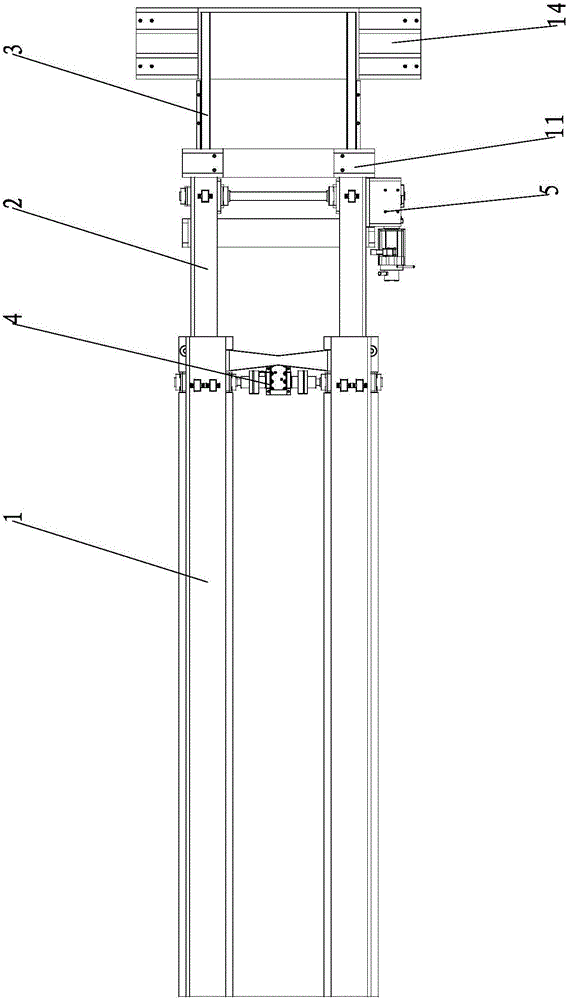

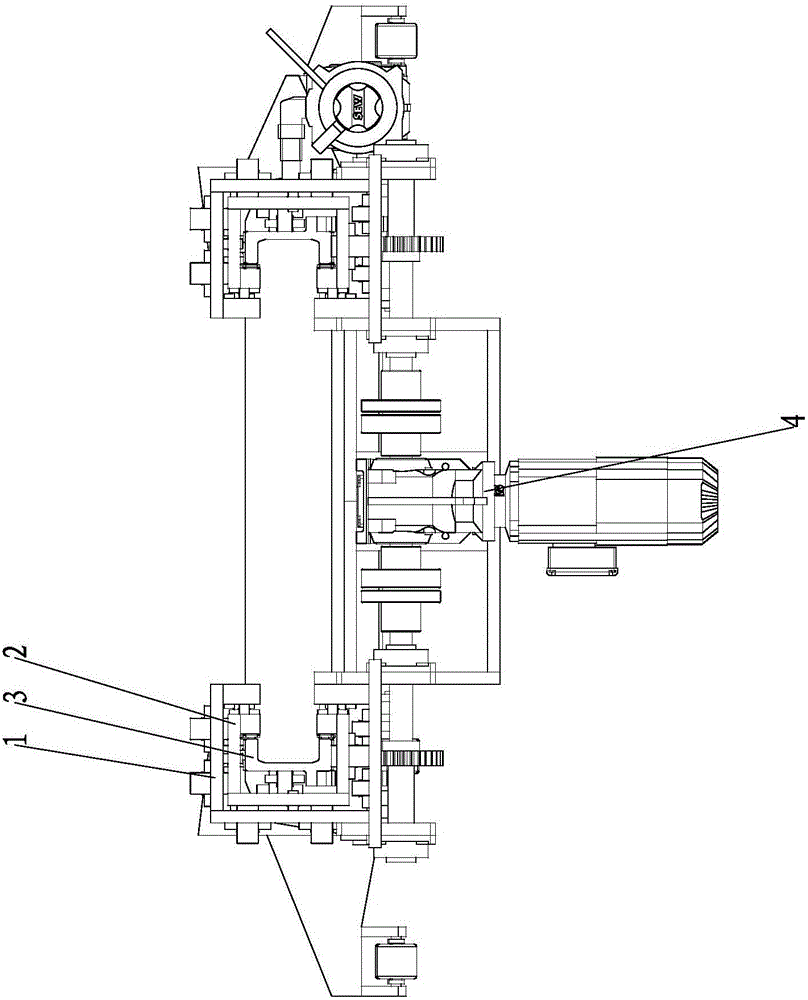

[0032] Such as Figure 1~3 As shown, the present invention mainly includes a primary track assembly 1 , a secondary track assembly 2 , a tertiary track assembly 3 , a secondary track drive component 4 and a tertiary track drive component 5 .

[0033] The primary track assembly 1 includes two primary tracks 6, and the two primary tracks 6 are symmetrically arranged left and right. One end of the two primary rails 6 is connected into one body through a secondary rail drive assembly mounting frame 7, and the secondary rail drive assembly mounting frame 7 is provided with a secondary rail drive assembly 4.

[0034] Such as Figure 4 As shown, the first-level track 6 includes a first-level track vertical plate 6.1, a first-level track upper plate 6.2, a first-level track lower plate 6.3, a first-level track upper load-bearing plate 6.4 and a first-level t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com