Automatic plate receiving device for PCB production

An automatic receiving and PCB board technology, applied in the direction of transportation and packaging, conveyors, conveyor objects, etc., can solve the problems of large manpower and material resources, consumption, PCB board damage, etc., to avoid PCB board damage and save space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

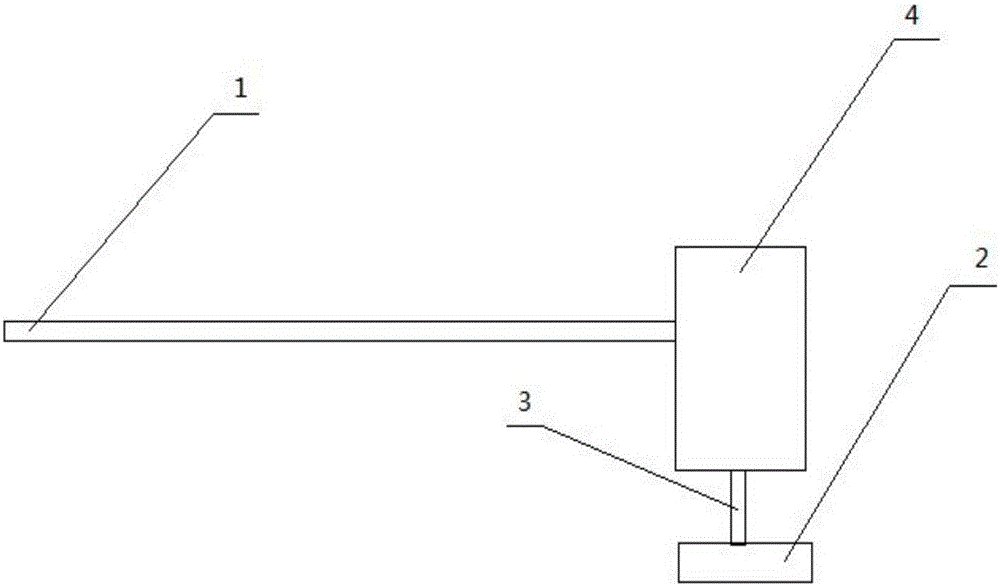

[0017] see figure 1 , is a specific embodiment of the present invention:

[0018] An automatic receiving board device used for PCB board production, the automatic receiving board device includes a switch, a transmission device and a recovery device, a base 2 is provided at the bottom of the recovery device, and a telescopic device is provided between the recovery device and the base 2; the switch is respectively connected to the transmission device and the recovery device. The recovery device is connected; the transmission device is actively connected with the recovery device.

[0019] The conveying device is a conveyor belt 1, the recycling device is a layered frame 4, and an infrared detection device is arranged on the layered frame 4.

[0020] The telescopic device is an electric telescopic rod 3, and at least three pulleys are arranged at the bottom of the base.

[0021] By adopting the PCB board automatic collection device, the damage of the PCB board during the manual ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com