Automobile shifting fork automatic manufacturing combined machine tool

A combined machine tool and automatic processing technology, which is applied to metal processing machinery parts, metal processing equipment, manufacturing tools, etc., can solve the problems of difficult to achieve shape and position tolerance, difficult to control product quality, and high labor intensity of workers, so as to ensure the shape and position Tolerance, reduce labor intensity of workers, improve production efficiency and the effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing:

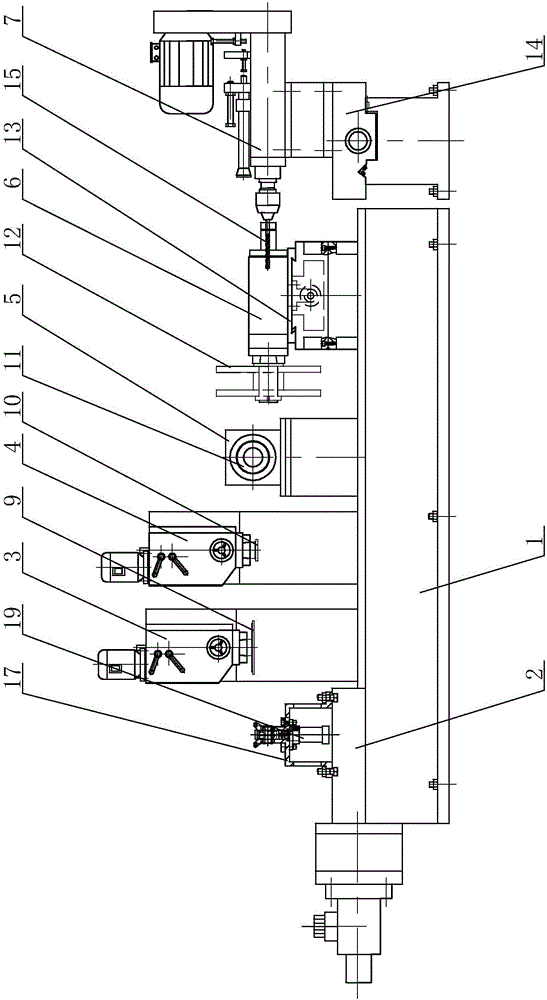

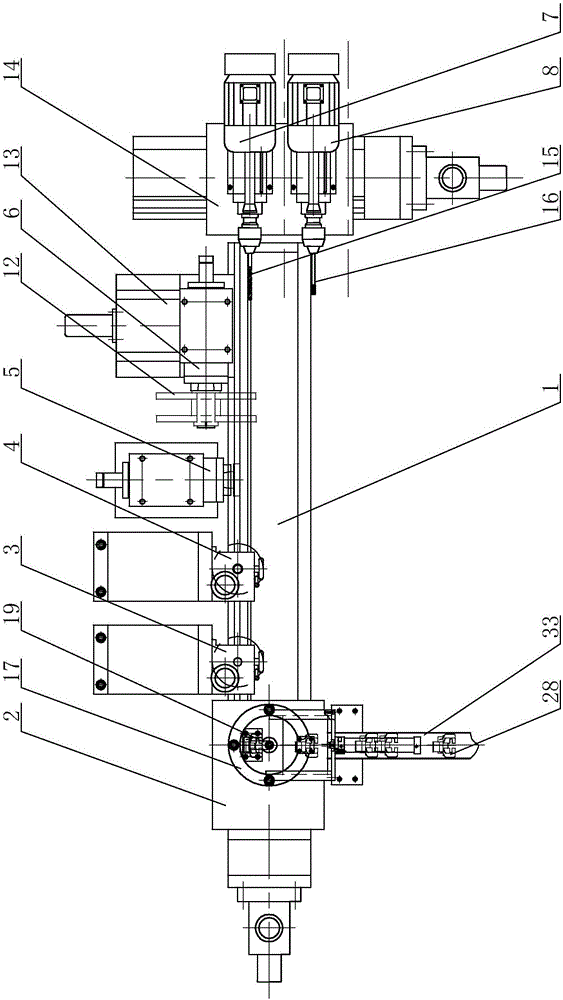

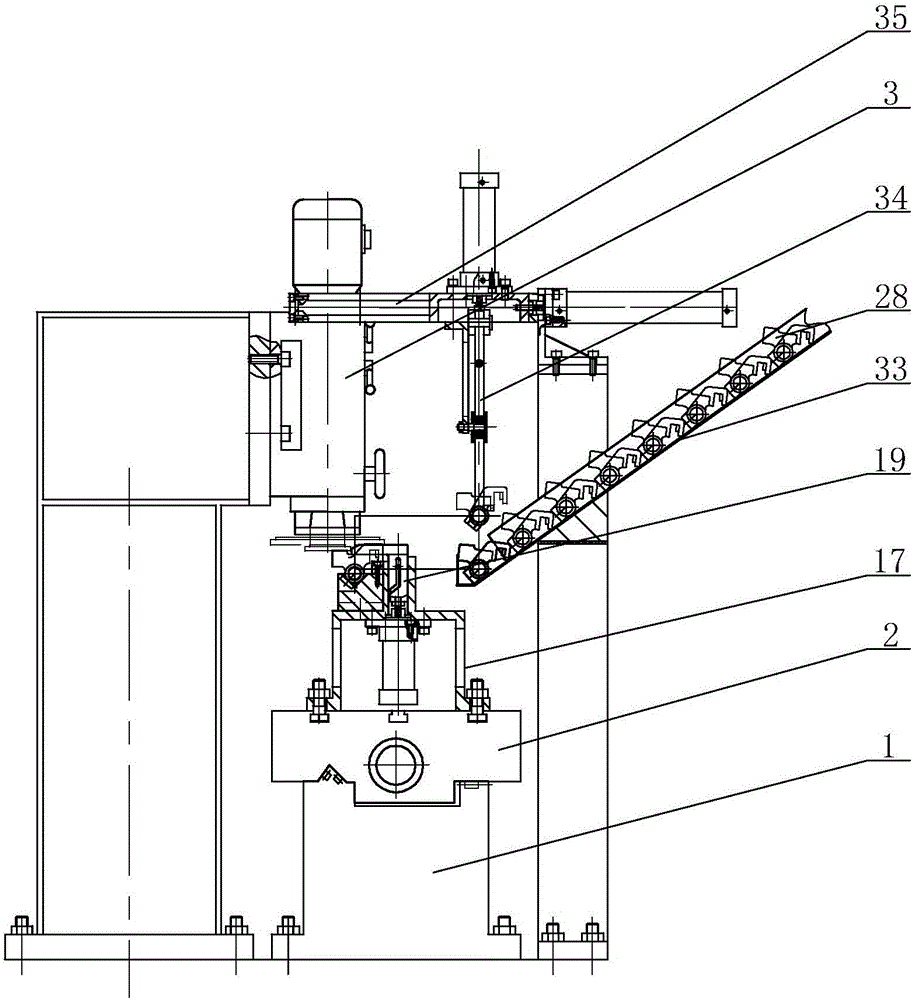

[0024] Depend on Figure 1 to Figure 14As shown, the automobile shift fork automatic processing combination machine tool includes a bed 1, and a horizontal numerical control slide table 2 sliding along the bed 1 is installed on the bed 1, and one side of the horizontal numerical control slide table 2 is provided There are workpiece conveying slides 33, pneumatic manipulator 34 and sliding frame 35. The pneumatic manipulator 33 is installed on the sliding frame 35 and can lift up and down and move horizontally. The top of the bed 1 is provided with the first upper plane milling machine from left to right. Power head 3, second upper plane milling power head 4, side plane milling power head 5, round table end face milling power head 6, drilling power head 7 and reaming power head 8, the first upper plane milling power head 3 1. The first upper plane milling cutter 9, the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com