Multipurpose stroke die shell for producing steel cable clamping piece

A technology of steel cable clips and mold shells, applied in the direction of manufacturing tools, forging/pressing/hammer devices, forging/pressing/hammering machinery, etc., can solve the problems of inconvenient production, cost waste, inconvenient production, etc., and achieve saving cost, avoid material waste, and facilitate production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

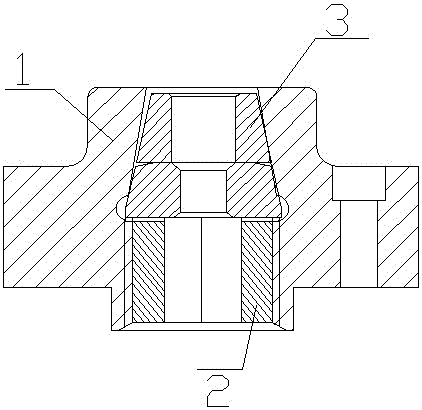

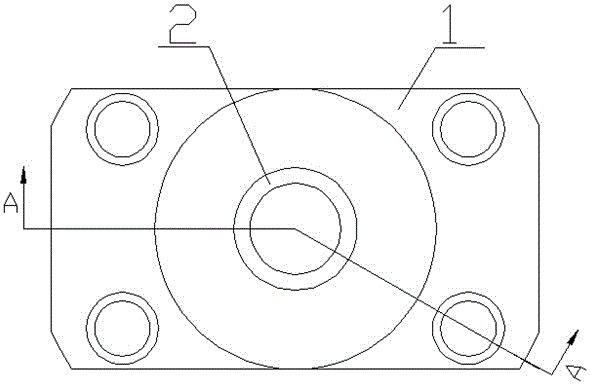

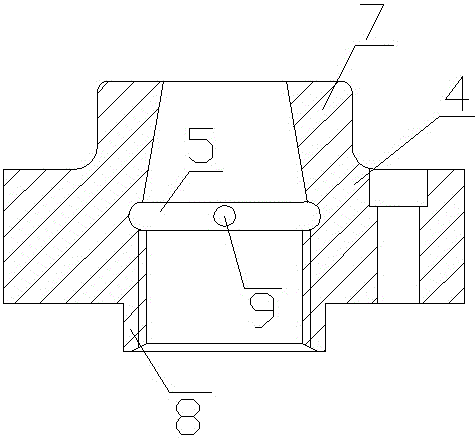

[0016] Such as figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 As shown, the present invention is used to produce the multi-purpose stroke formwork of steel cable clip, comprises formwork 1 and the inner hexagonal piercing nut 2 under formwork 1; Formwork 1 comprises middle boss 6, upper circular tube column 7 and the lower cylindrical column 8, the upper cylindrical column 7, the middle boss 6 and the lower cylindrical column 8 are integrally connected in sequence, the middle boss 6 is a cuboid, the middle of the middle boss 6 runs through a threaded through hole, and the middle boss 6 has a The thread of the threaded through hole extends to the inner wall of the lower circular pipe column 8, and the four corners of the central boss 6 are symmetrically provided with pin holes 4 penetrating through the middle boss 6, the outer pipe wall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com