A filter bag dust collector with a quick-change filter bag cage combination

A filter bag dust collector and quick-change technology, applied in membrane filters, dispersed particle filtration, chemical instruments and methods, etc., can solve the problems of time-consuming, inconvenient operation, low work efficiency, etc., and achieve convenient use and operation. Simple and efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

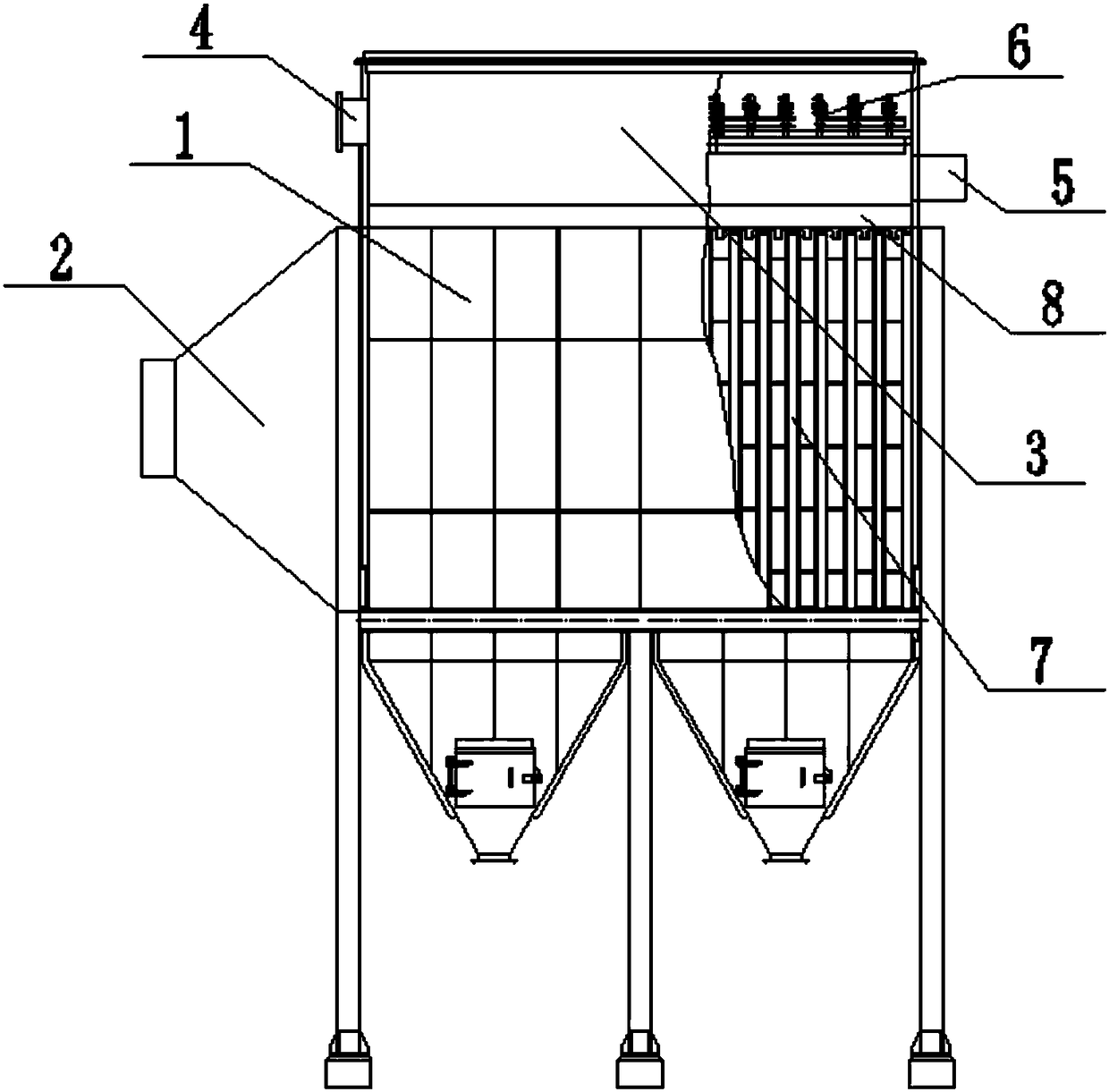

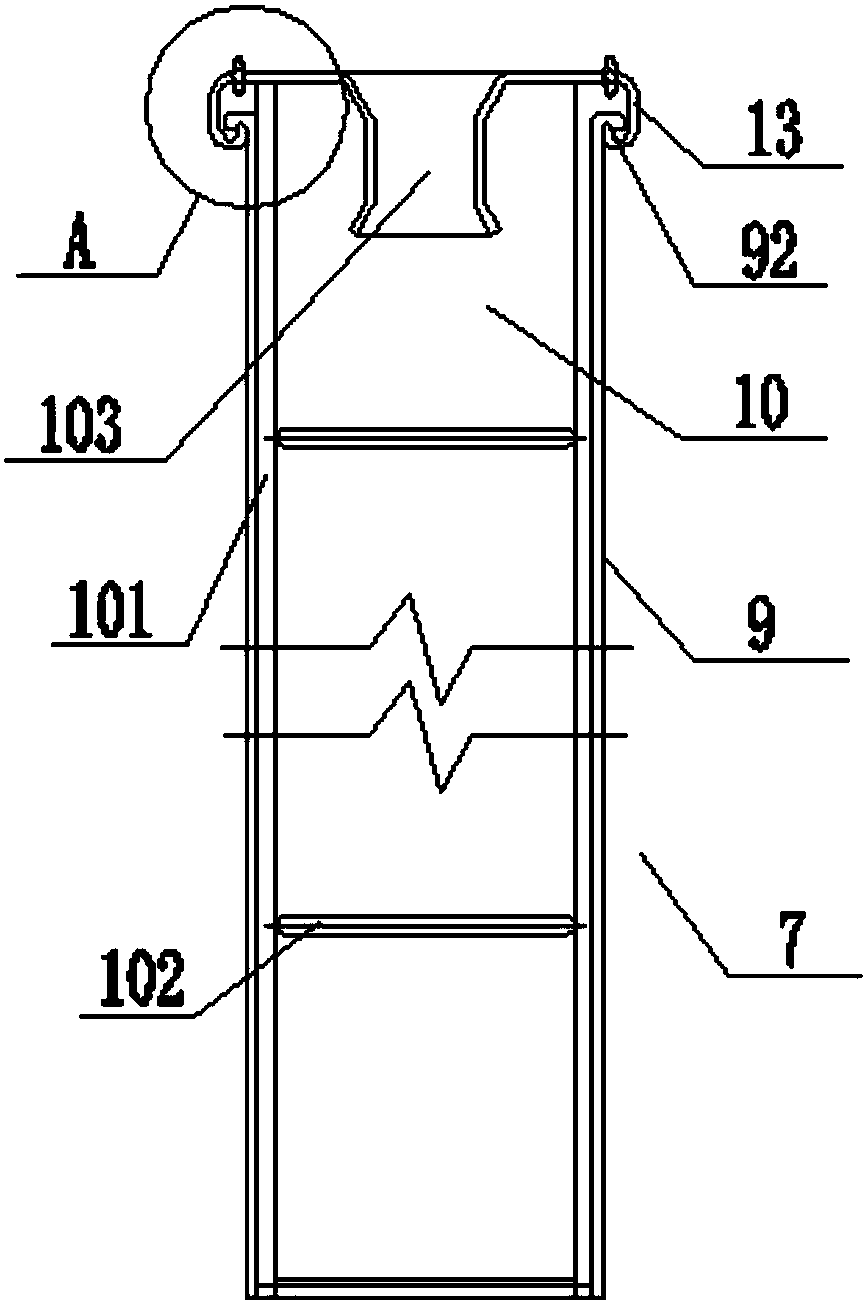

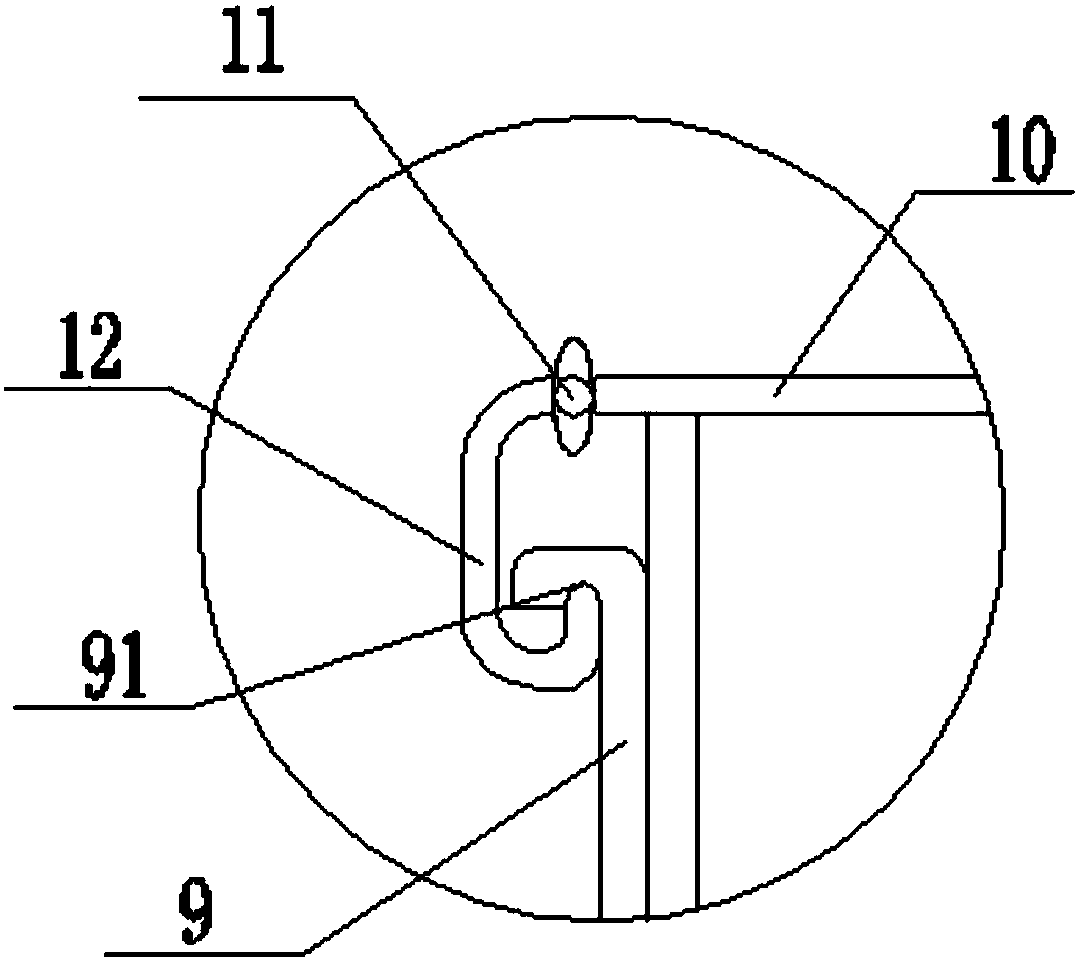

[0018] like Figure 1 to Figure 3 A filter bag filter with a combination of quick-change filter bag cages as shown includes a box body 1 and a clean air chamber 3, one side of the box body 2 is connected to the inlet 2, and the upper part of the box body 1 is connected to the clean air chamber 3, The clean air chamber 3 is provided with an air inlet 4 on the same side as the inlet 2 for connecting the fan, the other side of the clean air chamber 3 is provided with an outlet 5, and the clean air chamber 3 is provided with a blowing system 6. 1 is provided with a number of filter bag cage combinations 7, and several filter bag cage combinations 7 are equidistantly arranged on the porous plate 8 at the top of the box body 1, and each filter bag cage combination 7 is composed of a single filter bag 9 and a single cage. The frame 10 is composed of a single cage frame 10 which is a cage-shaped cylinder composed of a plurality of longitudinal bars 101 and a transverse inner hoop 102 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com