A friction torque testing machine for aerospace bearings under simulated weightlessness

A technology of friction torque and simulated weightlessness, applied in the direction of mechanical bearing testing, etc., can solve problems such as excessive starting friction torque, deformation and fracture of cage, poor operation, etc., and achieve the effect of short development cycle, low cost and long weightlessness time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

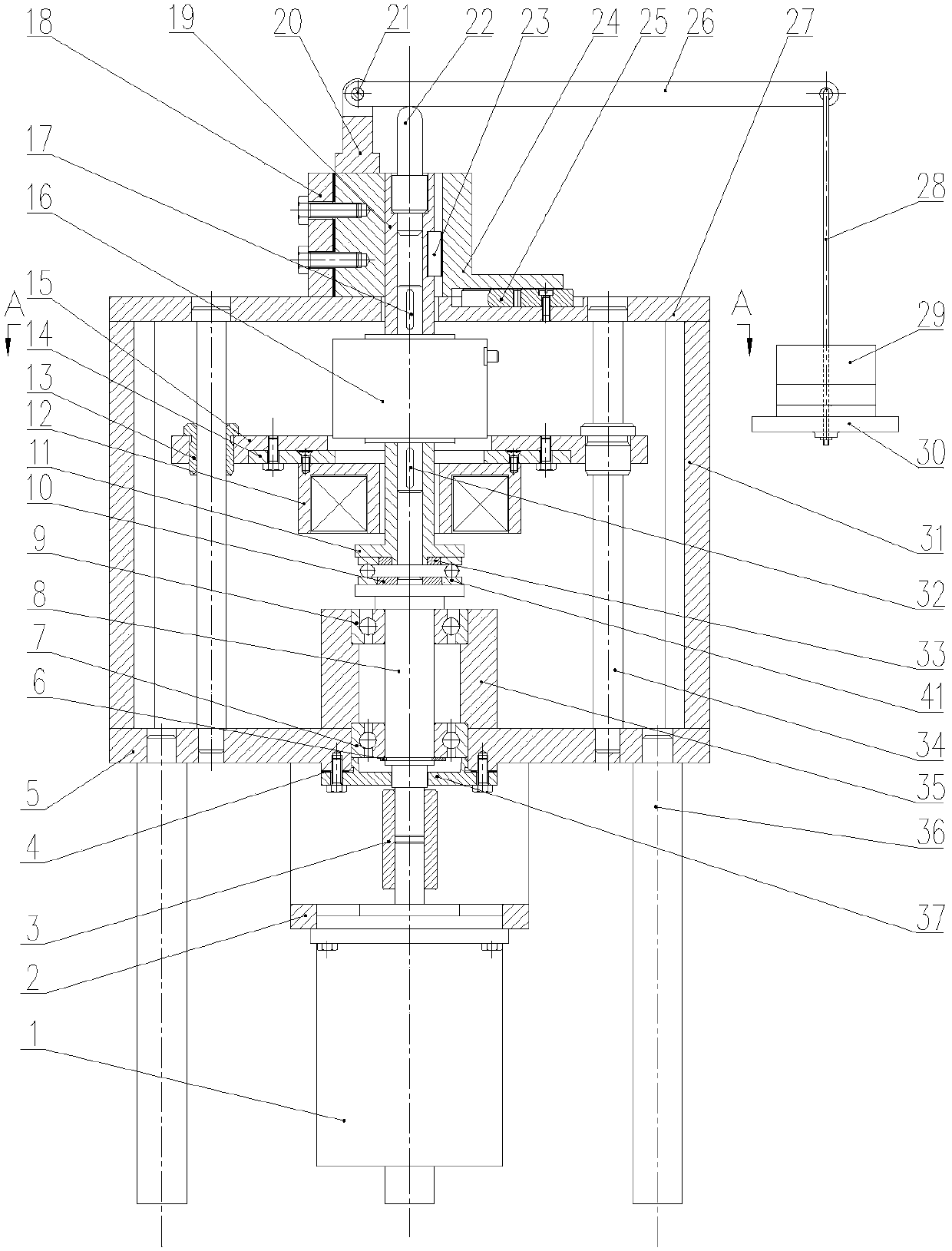

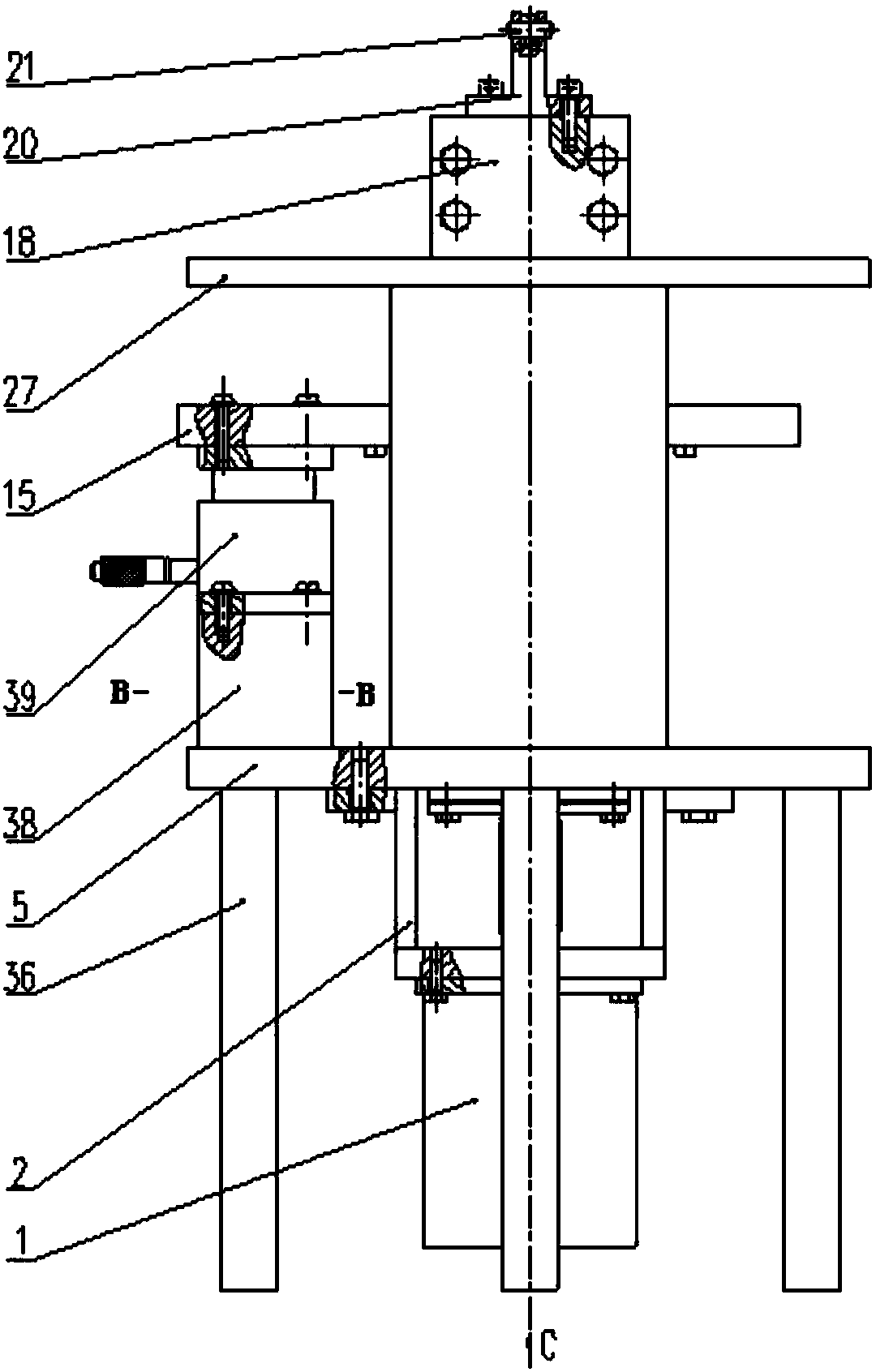

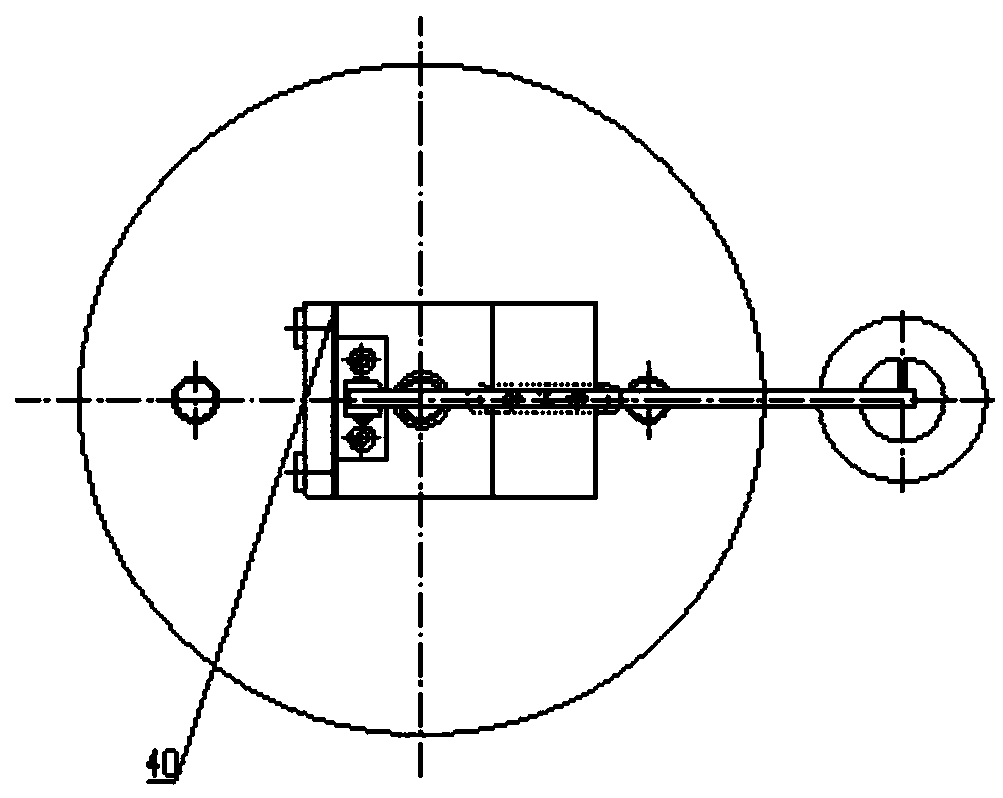

[0016] exist figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 In the schematic diagram of the present invention shown, the upper cover 27 and the lower cover 5 are connected by a column 31 and a guide rod 34, and a through hole is provided at the bottom of the lower cover, and a support rod 36 is inserted in each through hole. . The motor bracket 2 is fixed by bolts at the bottom of the lower cover. The motor bracket is a channel steel shell with an upper opening, and the lower surface of the motor bracket is provided with a through hole. The lower part of the motor bracket is connected to the motor 1 through bolts, and the output shaft of the motor extends to the inside of the motor bracket through the through hole of the motor bracket. The output shaft of the motor is connected with one end of the shaft coupling 3, and the other end of the shaft coupling is connected with the shaft 8. The bearing cover 37 is fixed on the bottom of the lower cover ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com