Roller feed drying equipment

A technology for drying equipment and feed, applied in drying, dryer, lighting and heating equipment and other directions, can solve the problems of water in the water tank not easy to circulate, the transmission device is easy to age, safety problems, etc., to achieve controllability and energy saving , Improve safety, and achieve the effect of controlling the amount of incoming and outgoing materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

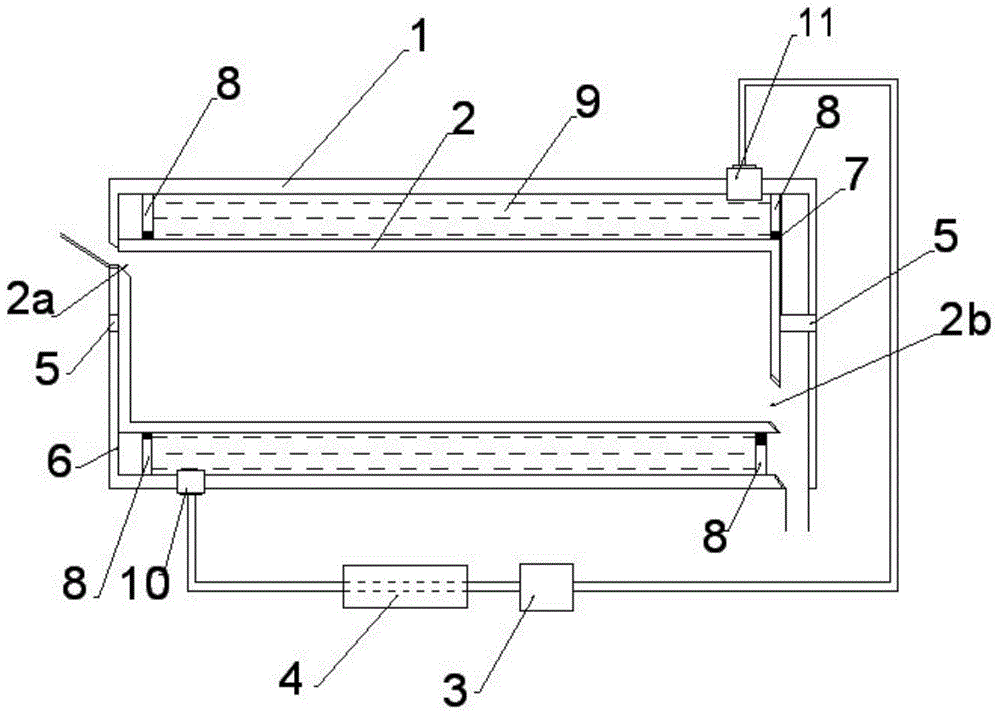

[0017] In the figure, 1 is the inner cylinder, 2 is the outer cylinder, 3 is the circulating pump, 4 is the heater, 5 is the connecting rod, 6 is the front baffle, 7 is the rear baffle, 8 is the sealing ring, 9 is the interlayer space, 10 is a fluid inlet, 11 is a fluid outlet, 2a is an inlet, and 2b is an outlet.

[0018] Such as figure 1 As shown, the drum feed drying equipment provided by the present invention includes an outer cylinder 1, an inner cylinder 2, a circulation pump 3 and a heater 4; The connecting rod is equipped with a motor, which can drive the inner cylinder to rotate; the front and rear walls of the inner cylinder are provided with a 2a feed port and a 2b discharge port; the front wall of the inner cylinder has a front baffle 6 on the outside There is an opening at the feed port of the cylinder; a rear baffle 7 is provided on the outer side of the rear wall of the inner cylinder, and the rear baffle 7 is provided with an opening near the outlet of the out...

Embodiment 2

[0023] In this embodiment, the drum feed drying equipment is basically the same as in Embodiment 1, in which the circulating fluid used is oil, and the temperature control equipment is used to control the circulating temperature. Due to the high boiling point of oil, such setting can improve the drying process. temperature to meet different usage needs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com