Structure for fixing plastic part and aluminum basal plate of LED drive

A technology of LED driver and aluminum substrate, applied in the direction of light source fixing, lighting device parts, semiconductor devices of light-emitting components, etc., can solve the problems of easy aging of two wires, inconvenient replacement, complex structure, etc., and achieve convenient and fast installation and connection. , The effect of firm connection and simple overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

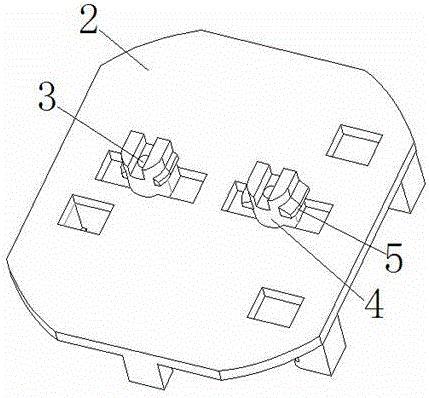

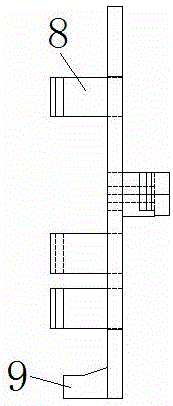

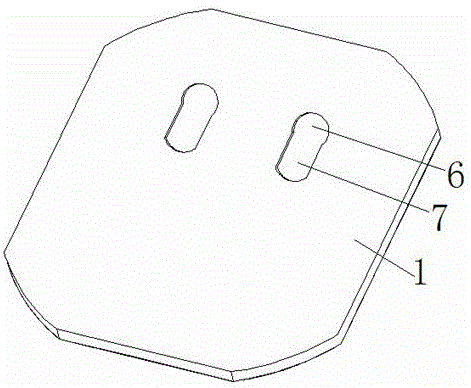

[0016] Such as figure 1 , figure 2 and image 3 As shown, the structure of the fixed LED-driven plastic parts and the aluminum base plate of the present invention includes an aluminum base plate 1 and a plastic plate 2, and a connection hole is provided on the aluminum base plate 1, and the side close to the aluminum base plate 1 The plastic plate 2 is provided with a connection fixture, and the connection fixture is matched with the connection hole, the aluminum substrate 1 and the plastic plate 2 are fixed by the connection fixture, and the plastic plate 2 is provided with a pin through hole 3; The connection fixture is a buckle fixture, which is composed of a pin 4 and a fastening connection edge 5 arranged on the pin 4; the connection hole is divided into two parts, including a large-diameter assembly part 6 and a small-diameter tight connection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com