A New Technology for Preventing Secondary Crack Repair in Leakage Treatment by Slotting Method

A new technique, the technique of slotting method, is applied in water conservancy projects, marine engineering, construction, etc. It can solve the problems of chemical grouting such as grout leakage, grout running, and low initial bonding performance, so as to improve the grouting quality and avoid grout leakage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

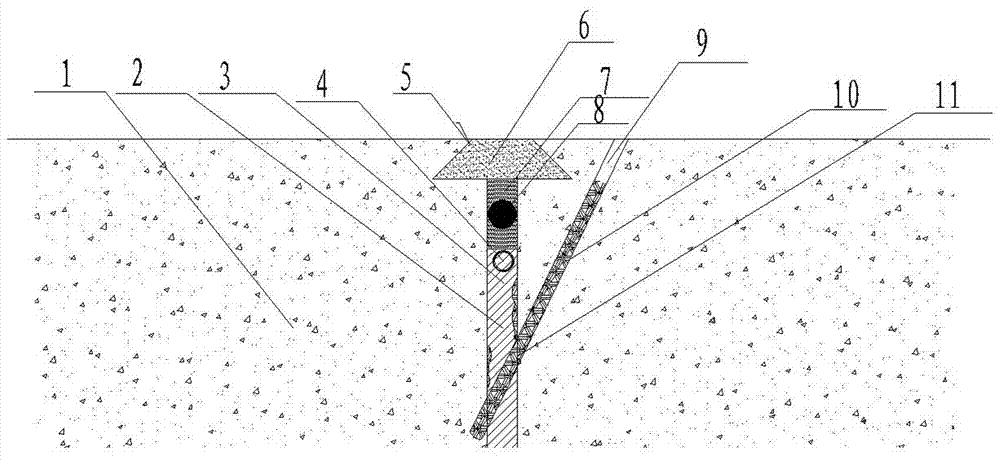

[0017] The new technology of preventing secondary cracking and repairing in the leakage treatment of slotting method, through more than 100 tests, determined the method of laying dovetail grooves with an opening width of 4cm, a bottom width of 10cm, and a depth of 3cm on the surface of cracks or expansion joints . Wall saws, angle grinders, angle rulers and other equipment are used in the construction, and the slotting form can be well realized. Through the use of the angle ruler and the wall saw, the angle of the beveled edge of the groove can be determined, the continuous operation can be realized through the guide rail of the wall saw, and the groove can be excavated without damage by using tools such as angle grinder and small electric pick to ensure the beveled edge of the groove not destroyed. Specific process flow: Lay rubber 8 up and down in the expansion joint (expansion joint in this example) 2

[0018] And the guide pipe 4, the expansion joint between the guide pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com