A chain protection mechanism and a crawler walking device

A technology for guard chain and crawler chain, which is applied in the directions of crawler vehicles, motor vehicles, transportation and packaging, etc., can solve the problems of reducing the service life of guard plates, wear of guard plates, derailment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

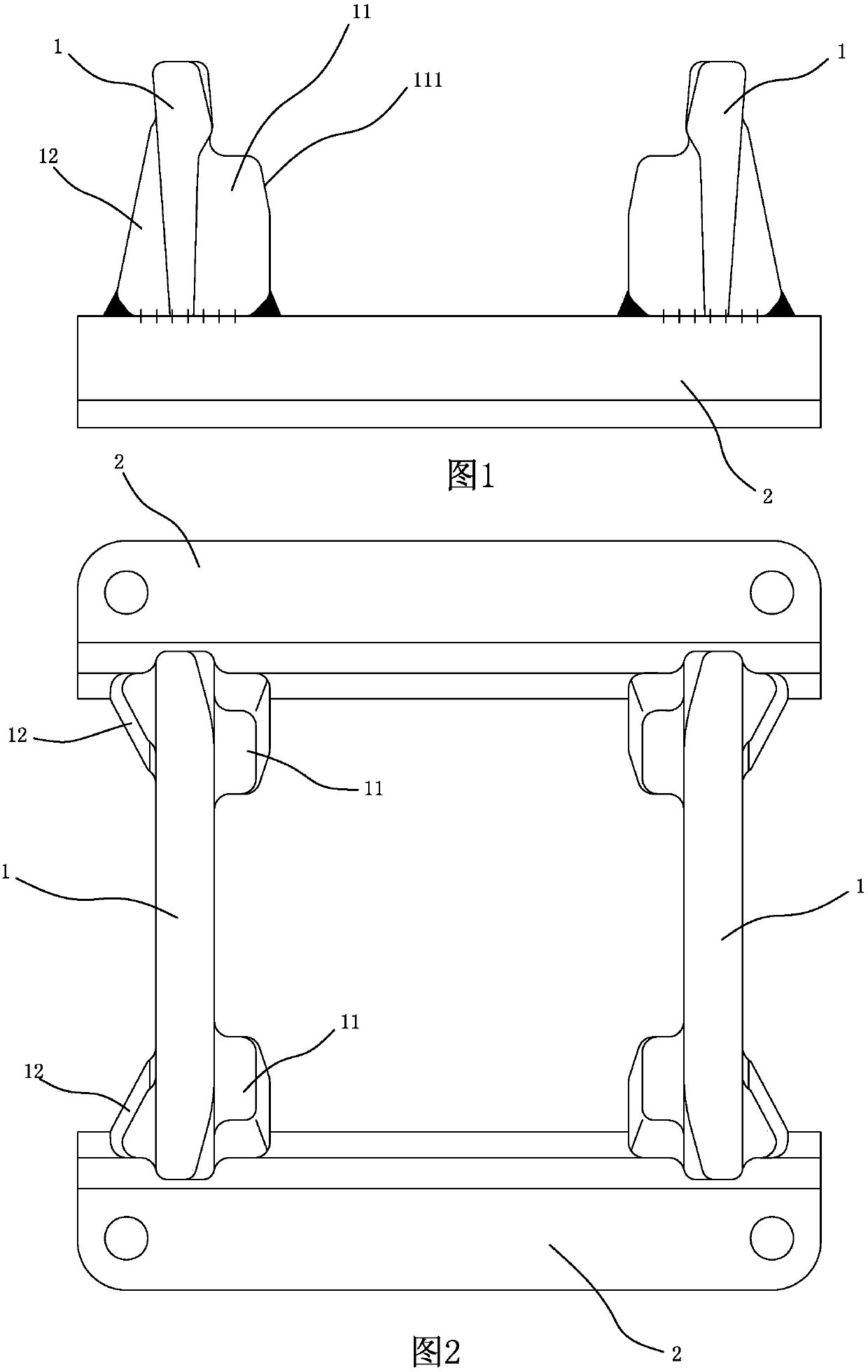

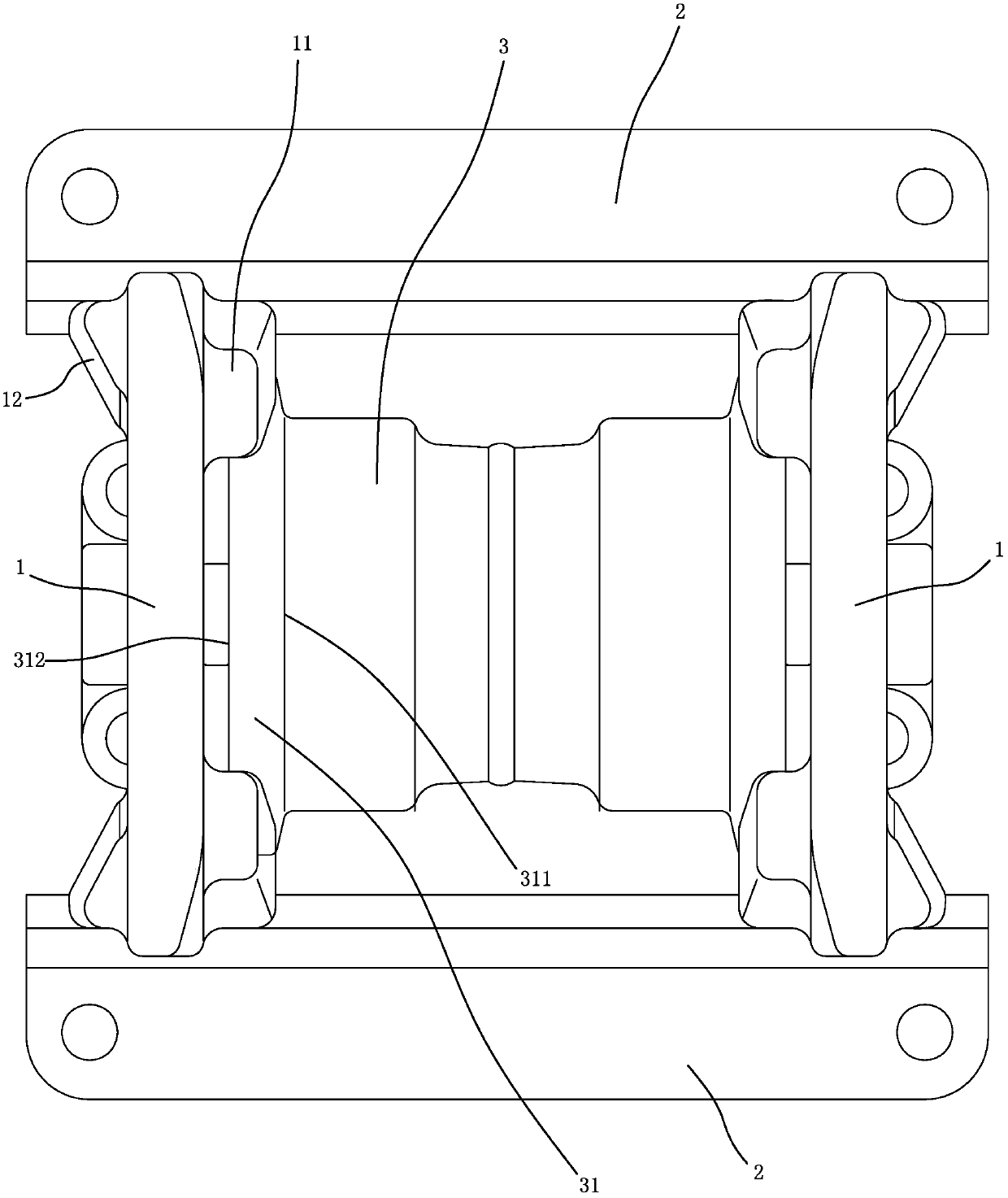

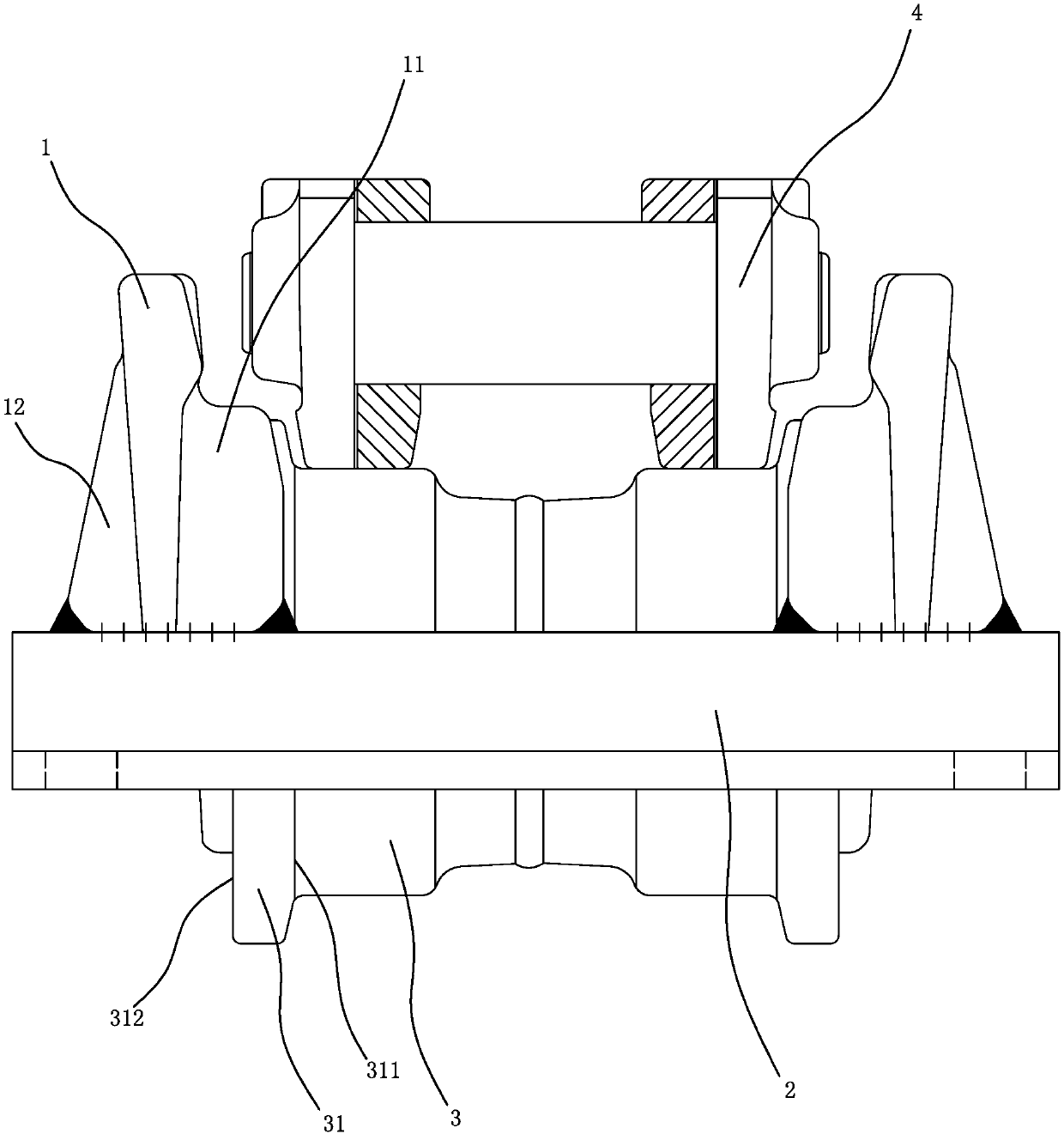

[0024] Refer to Figure 1 to Figure 5 As shown, a chain protection mechanism includes two mounting beams 2 and two guard plates 1 for preventing the crawler chain rail 4 from detaching from the roller 3 .

[0025] The supporting roller 3 is installed at the bottom of the track frame, and the two installation beams 2 are installed on the bottom of the track frame in parallel and opposite, and are located on both sides of the supporting wheel 3. On the outside of the flanges 31 at both ends of the roller 3, the track chain rail 4 is limited between the two guard plates 1 to be supported by the roller 3, and the opposite surfaces of the two guard plates 1 are respectively provided with flanges located on the roller 3 The two baffle plates 11 on both sides of 31, the upper end of the baffle plate 11 is higher than the top of the roller 3 flange 31 to prevent the track chain rail 4 from jumping up the roller flange 31, and the opposite sides of the two guard plates 1 are respective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com