Transfer cart for welding machines and gas cylinder

A kind of welding machine and gas cylinder technology, applied in the direction of welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of unsafe and convenient transport welding machines, achieve convenient and free movement, improve work efficiency, and save time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

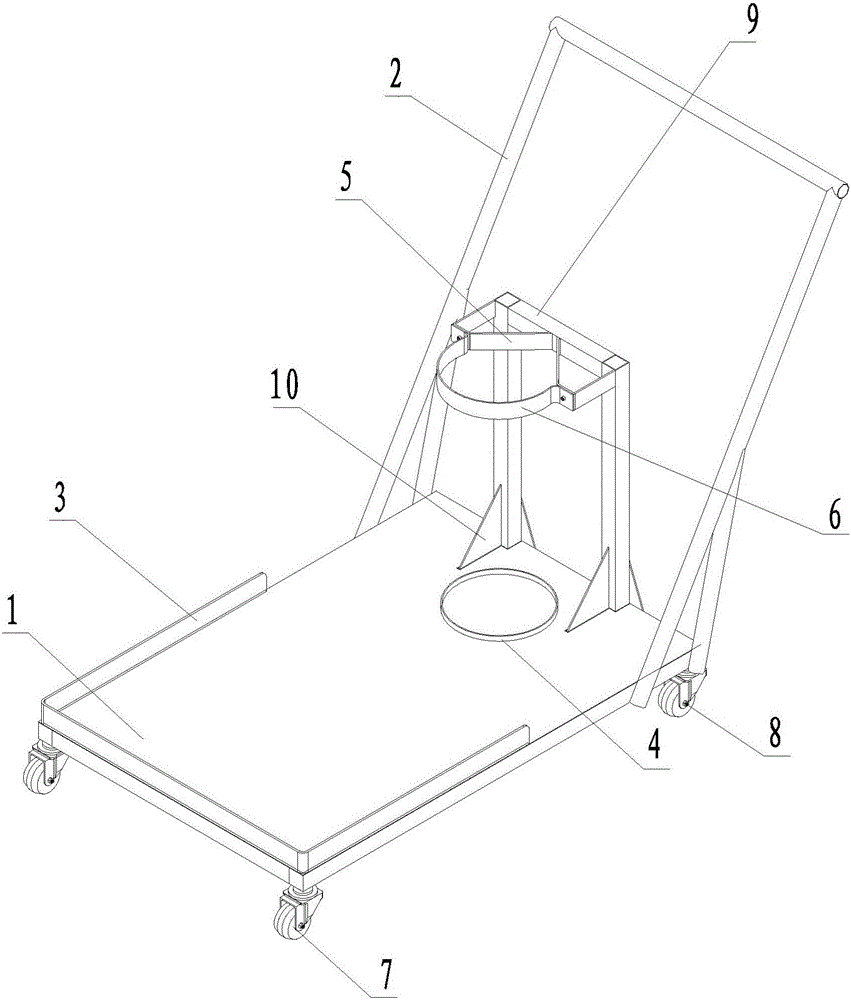

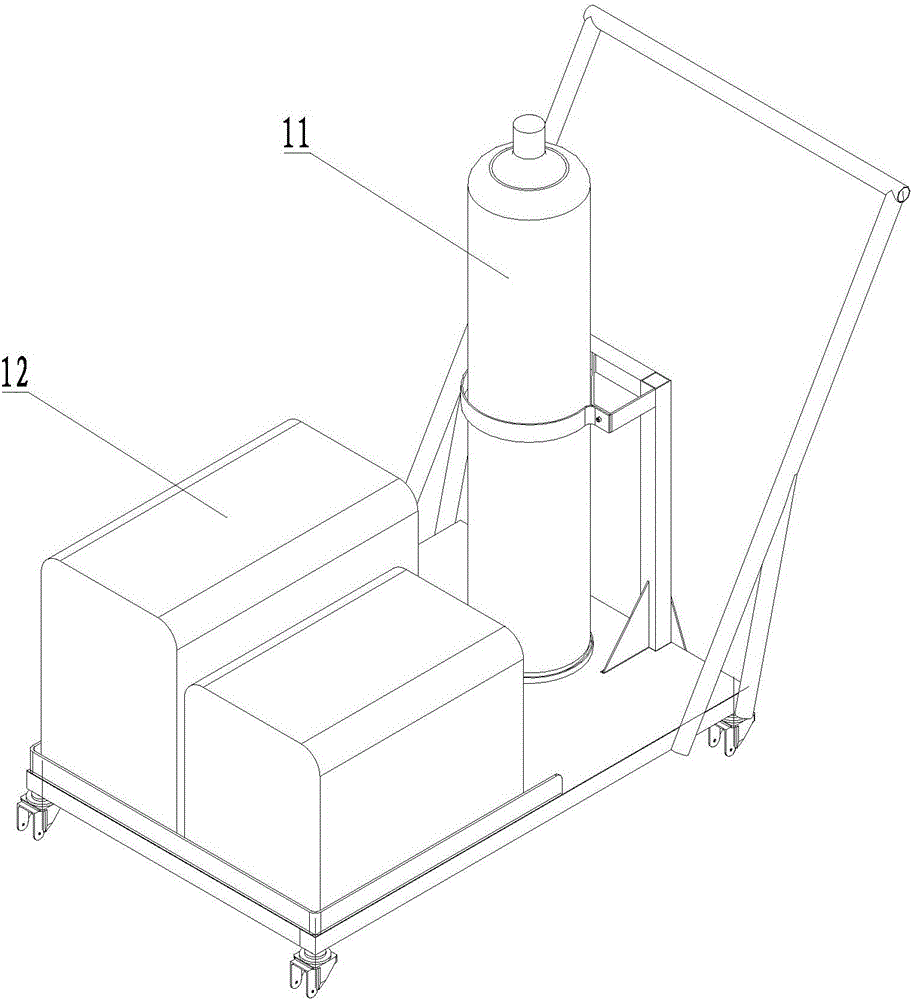

[0016] like figure 1 Shown: a transfer trolley for welding machines and gas cylinders, including a base 1, handrails 2, wheels, welder fixing panels 3 and gas cylinder 11 fixing parts; The first clamping part 4 and the second clamping part arranged above the first clamping part 4, the first clamping part 4 is a ring structure, and the second clamping part consists of a V-shaped backrest plate 5 and a semicircular One end of the semicircular snap ring 6 is hinged to one end of the V-shaped backrest 5, and the other end of the semicircular snap ring 6 is detachably fixed on the other end of the V-shaped backrest 5 by a fixing piece. ; The welding machine fixed coaming 3 is composed of left, right and front baffles.

[0017] Preferably, elastic rubber is provided at the contact between the semicircular snap ring 6 and the V-shaped back plate 5 and the cylinder 11 .

[0018] Preferably, four wheels are provided, including two directional wheels 7 and two universal wheels 8 .

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com