A kind of preparation method of sulfurized platinum-rhenium reforming catalyst

A reforming catalyst and vulcanization-type technology, which is applied in the direction of physical/chemical process catalysts, naphtha catalytic reforming, chemical instruments and methods, etc., can solve the problems of reaction equipment corrosion, high cost and toxicity of vulcanizing agents, and achieve high activity The effect of improving stability and improving deposition dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

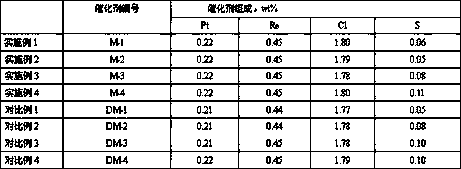

Embodiment 1

[0026] (1) Prepare an aqueous solution of N-cyanoethyl-N-hydroxyethylaniline with a concentration of 0.24wt%, and adjust the pH value of the treatment solution to 8.5 with ammonia water; add carbon disulfide dropwise to the aqueous solution under stirring to prepare the treatment solution, in which carbon disulfide The mass ratio of N-cyanoethyl-N-hydroxyethylaniline is 1:2.49.

[0027] (2) Dissolve chloroplatinic acid, perrhenic acid, and hydrochloric acid in deionized water to prepare an impregnating solution containing 0.19wt% platinum, 0.38wt% rhenium, and 1.5wt% chlorine. Measure 12 milliliters of impregnation solution containing 0.19wt% platinum, 0.38wt% rhenium and 1.5wt% chlorine and pour it into a 100ml beaker, take 10g strip-shaped γ-alumina (specific surface area 235m 2 / g, pore volume 0.58ml / g) was poured into it, soaked for 3 hours, filtered, dried at 105°C for 6 hours, and calcined at 450°C for 6 hours to obtain a catalyst intermediate.

[0028] (3) Take the tre...

Embodiment 2

[0030] (1) Prepare an aqueous solution of N-cyanoethyl-N-hydroxyethylaniline with a concentration of 0.20 wt%, and adjust the pH value of the treatment solution to 9.5 with ammonia water; add carbon disulfide dropwise to the aqueous solution under stirring to obtain the treatment solution, wherein The mass ratio of carbon disulfide to N-cyanoethyl-N-hydroxyethylaniline is 1:2.50.

[0031] (2) Dissolve chloroplatinic acid, perrhenic acid and hydrochloric acid in deionized water to prepare an impregnating solution containing 0.19wt% platinum, 0.38wt% rhenium and 1.5wt% chlorine. Measure 12 milliliters of impregnation solution containing 0.19wt% platinum, 0.38wt% rhenium and 1.5wt% chlorine and pour it into a 100ml beaker, take 10g strip-shaped γ-alumina (specific surface area 235m 2 / g, pore volume 0.58ml / g) was poured into it, soaked for 3 hours, filtered, dried at 105°C for 6 hours, and calcined at 450°C for 6 hours to obtain a catalyst intermediate.

[0032] (3) Take the tre...

Embodiment 3

[0034] (1) Prepare an aqueous solution of N-cyanoethyl-N-hydroxyethylaniline with a concentration of 0.32wt%, and adjust the pH value of the treatment solution to 9.5 with ammonia water; add carbon disulfide dropwise to the aqueous solution under stirring to obtain the treatment solution, wherein The mass ratio of carbon disulfide to N-cyanoethyl-N-hydroxyethylaniline is 1:2.53.

[0035] (2) Dissolve chloroplatinic acid, perrhenic acid and hydrochloric acid in deionized water to prepare an impregnating solution containing 0.19wt% platinum, 0.38wt% rhenium and 1.5wt% chlorine. Measure 12 milliliters of impregnation solution containing 0.19wt% platinum, 0.38wt% rhenium and 1.5wt% chlorine and pour it into a 100ml beaker, take 10g strip-shaped γ-alumina (specific surface area 235m 2 / g, pore volume 0.58ml / g) was poured into it, soaked for 3 hours, filtered, dried at 105°C for 6 hours, and calcined at 450°C for 6 hours to obtain a catalyst intermediate.

[0036] (3) Take the trea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com