An ultrasonographic method used for weld seam detection

An ultrasonic imaging method and welding seam detection technology, which is applied in the direction of using sound waves/ultrasonic waves/infrasonic waves to analyze solids, etc., can solve the problems of low detection speed, inaccurate quantification and positioning, and low imaging resolution of defect areas, so as to improve imaging Effects on quality, avoidance of accidents, guaranteed performance and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

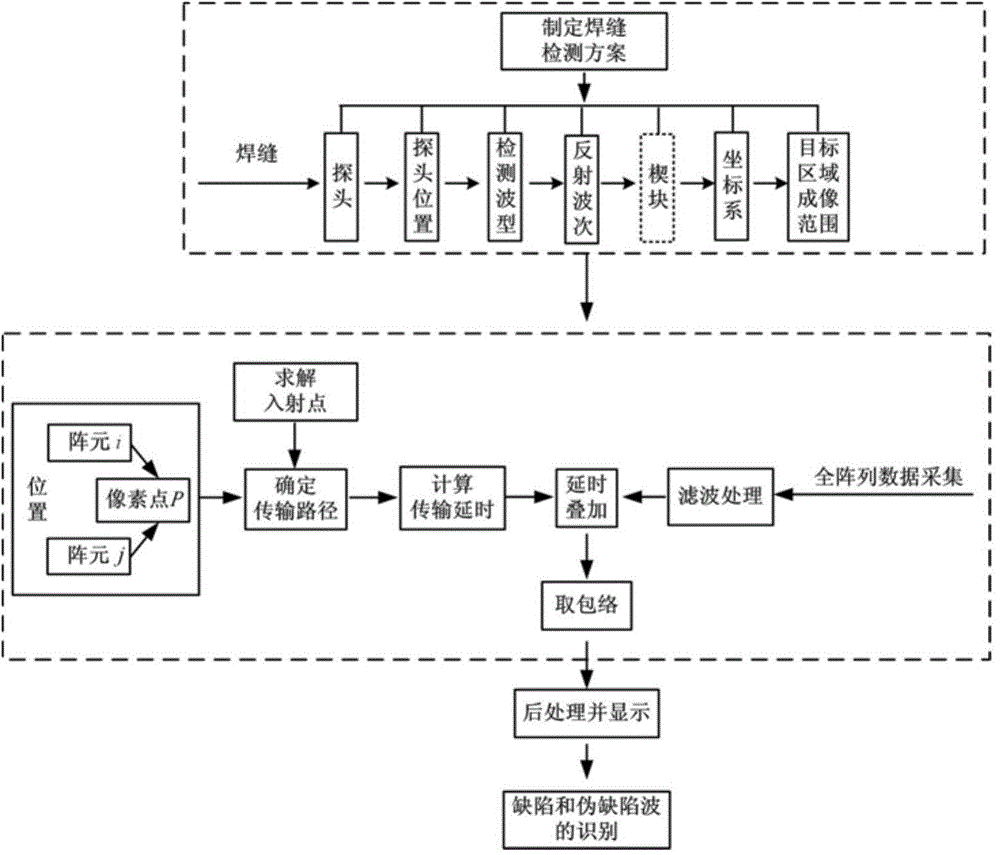

[0029] An ultrasonic imaging method for weld seam detection according to the present invention will be described in detail below with reference to the accompanying drawings and embodiments.

[0030] An ultrasonic imaging method for weld seam detection according to the present invention, the ultrasonic imaging method comprises:

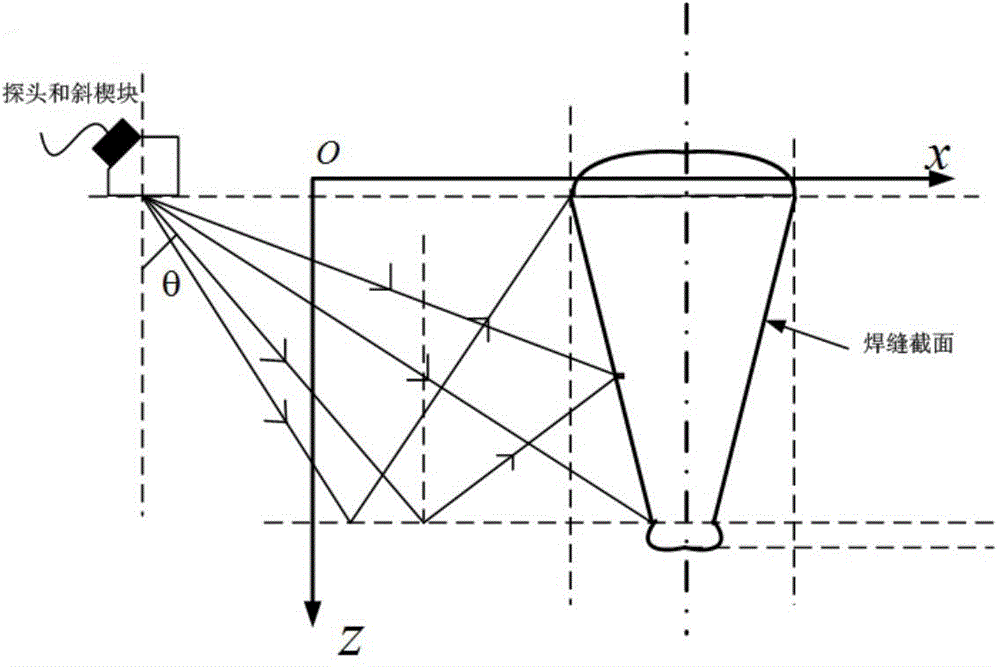

[0031] Step 1) According to the shape and size of the workpiece to be tested and the position of the weld on the workpiece, combined with the geometric dimensions of the ultrasonic phased array probe, determine the position of the ultrasonic phased array probe, the waveform of the ultrasonic wave, the number of echoes detected and The imaging range of the target detection area; when using the ultrasonic phased array to detect the workpiece weld, due to the influence of various factors such as the shape and size of the workpiece, the width of the sound beam, near-field interference, and the detection environment, it needs to be selected according to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com