Top corrosion testing device of wet gas loop

A corrosion test and loop technology, used in measuring devices, weather resistance/light resistance/corrosion resistance, instruments, etc., can solve the problems that the condensation kettle cannot be completely simulated, and the electrochemical corrosion behavior cannot be obtained, so as to achieve long service life, Highly adaptable and maneuverable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

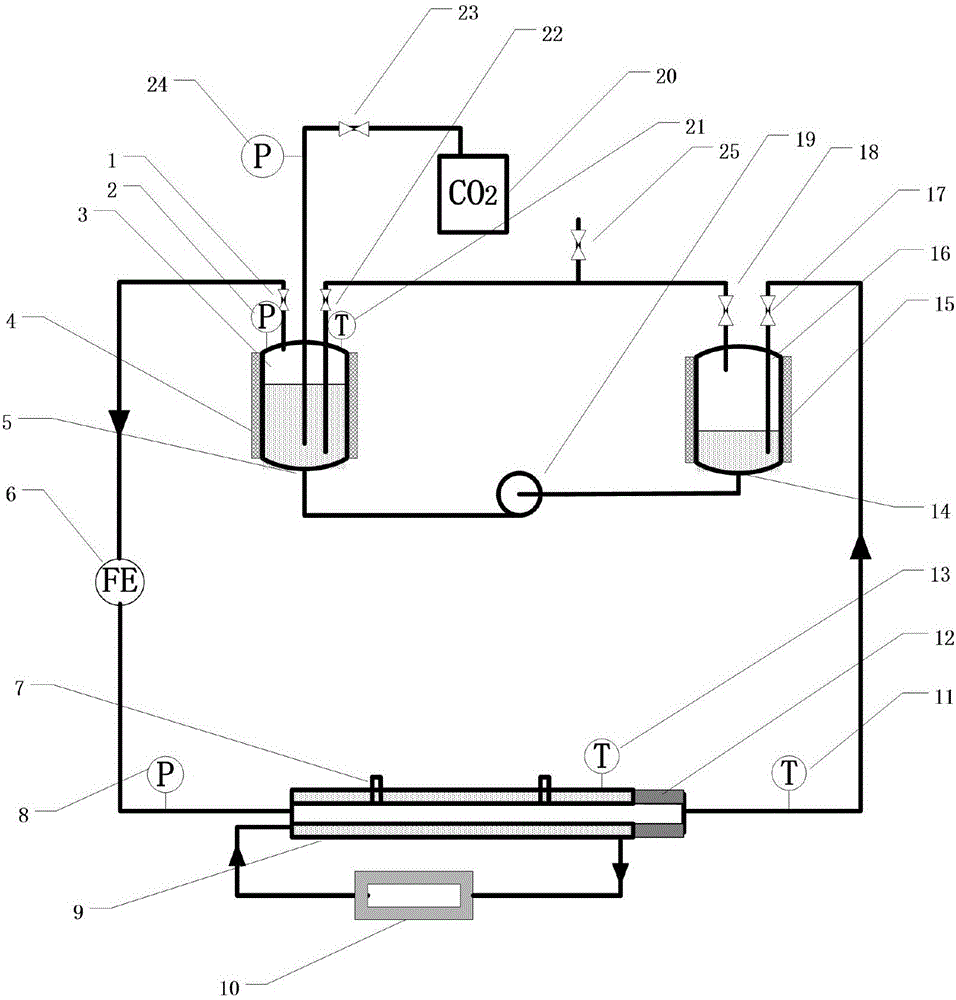

[0012] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the accompanying drawings and specific implementation methods.

[0013] The invention provides a moisture loop top corrosion testing device, which includes a heating kettle, a pipeline circulation system, a heating and heat preservation system, a circulating condensed water tank refrigeration system, a circulation pump, a signal conduction path, an external control box, a flow state observation window, External gas supply system, three-electrode system, electrochemical workstation and computer, etc.; the heating kettle includes heating kettle A (3) and heating kettle B (16); the pipeline circulation system includes various sections of pipelines; the heating insulation system includes heating kettle The heating device A (4), heating device B (15), the temperature sensor C (21) on the kettle and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com