High-pressure control valve flow optimization device and method for turbine unit

A technology of high-pressure valve adjustment and flow optimization, which is applied to measuring devices, mechanical equipment, engine components, etc., and can solve problems such as load disturbances that cannot be eliminated

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0091] The standard parts used in the present invention can be purchased from the market, and the special-shaped parts can be customized according to the instructions and the records of the accompanying drawings. The specific connection methods of each part adopt mature bolts, rivets, welding , pasting and other conventional means, no longer described in detail here.

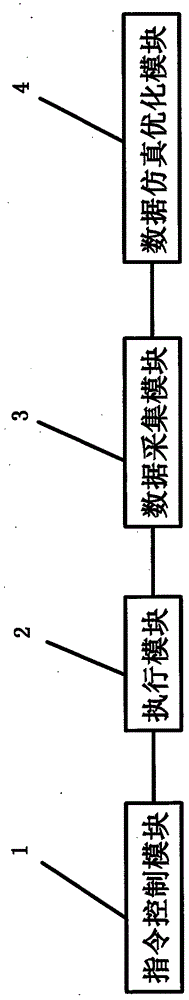

[0092] refer to Figure 1-5 , a specific embodiment of the present invention includes an instruction control module 1, which is used to send the opening degree signal of each adjustment door;

[0093] Executing module 2, used to receive instructions and control the opening of each adjustment door;

[0094] The data collection module 3 is used to collect real-time parameters such as the regulating stage pressure and the main steam pressure of the steam turbine;

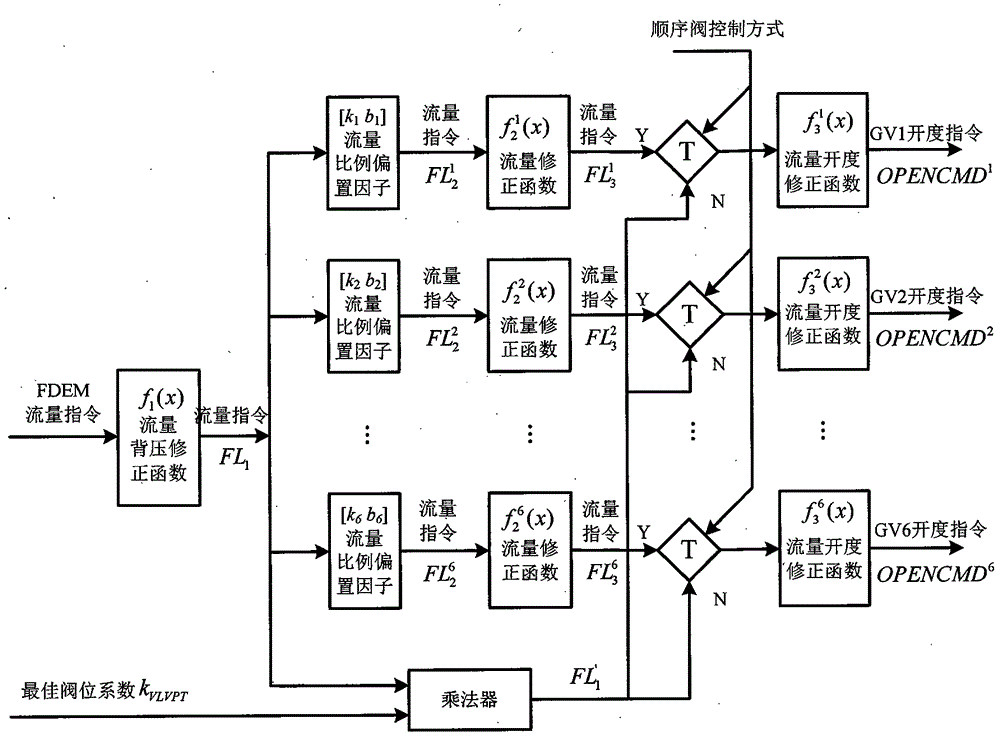

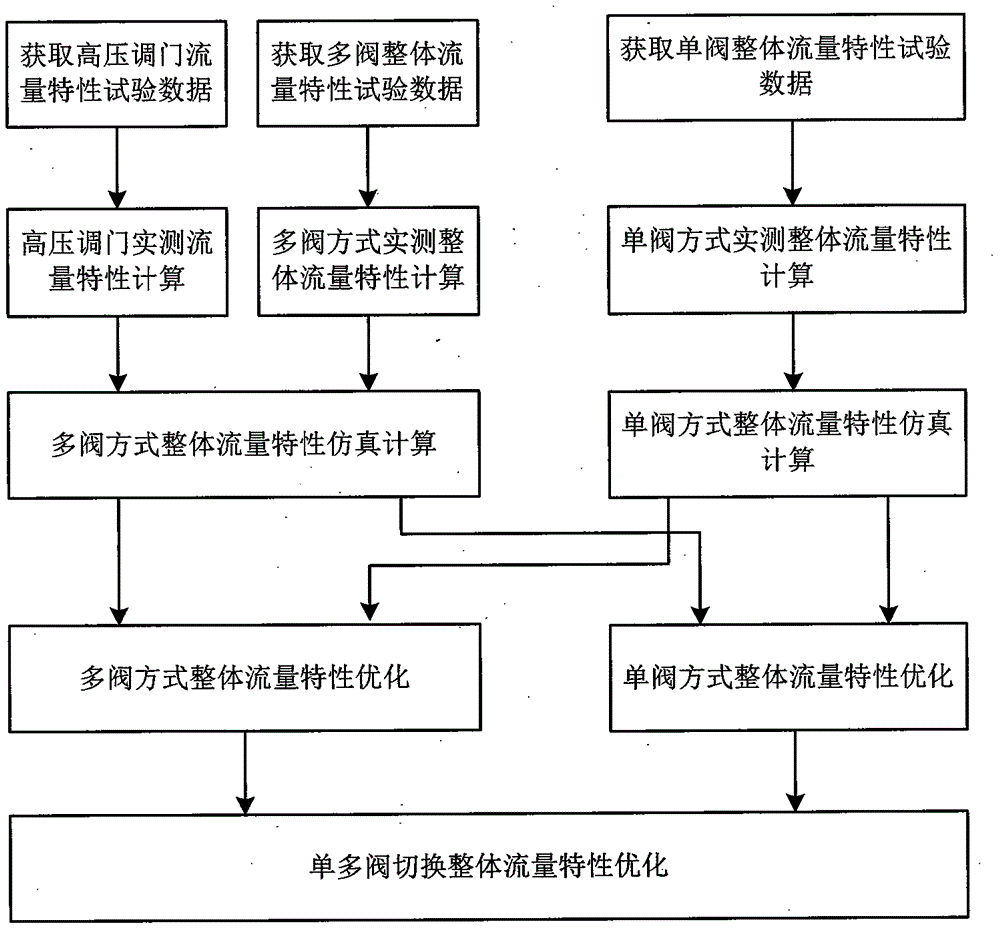

[0095] The data simulation optimization module 4 is used for performing data simulation and optimizing the flow characteristic curve according to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com