Supporting type temporary supporting method with telescopic top beams for tunneling face

A technology for excavation working face and temporary support, which is applied in the direction of mine roof support, earthwork drilling, mining equipment, etc. It can solve the problems of tension in excavation connection, small support area of front frame and rear frame, poor safety, etc., and achieve a balance The effect of mining relationship, increasing monthly footage, and large support length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

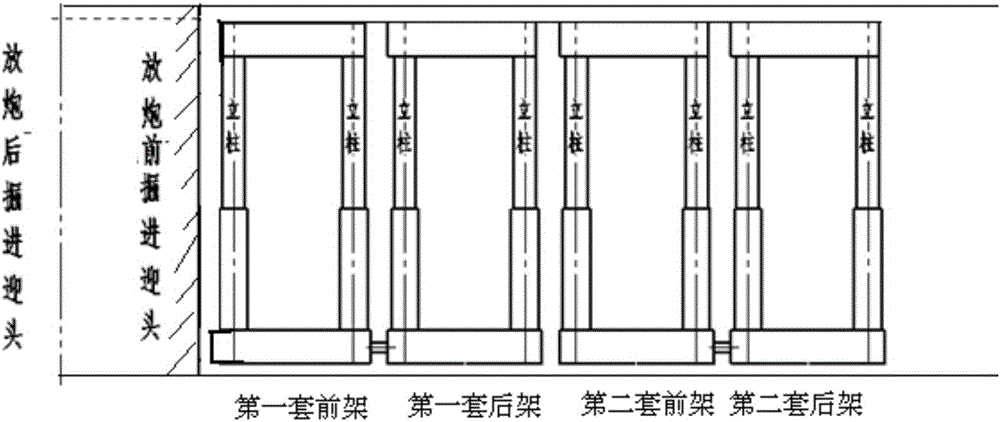

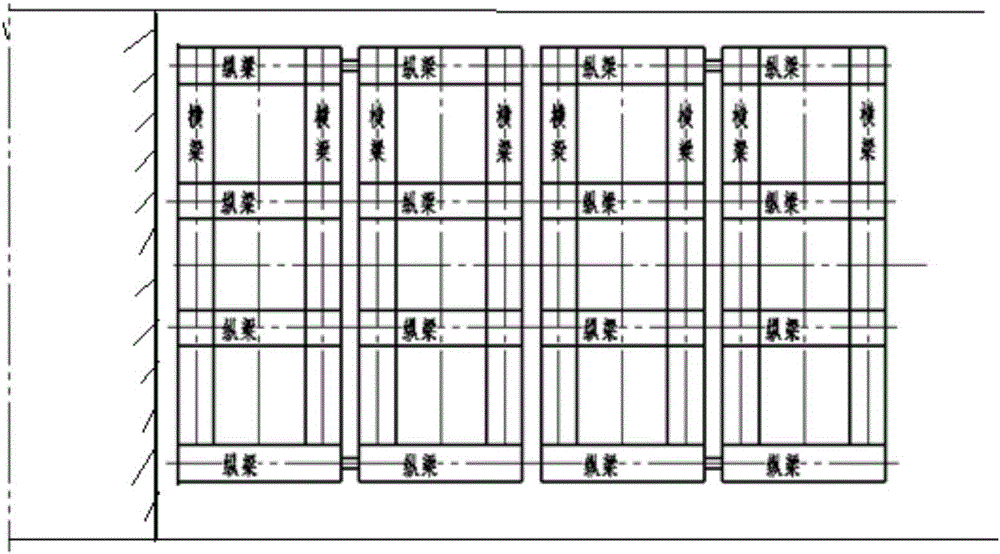

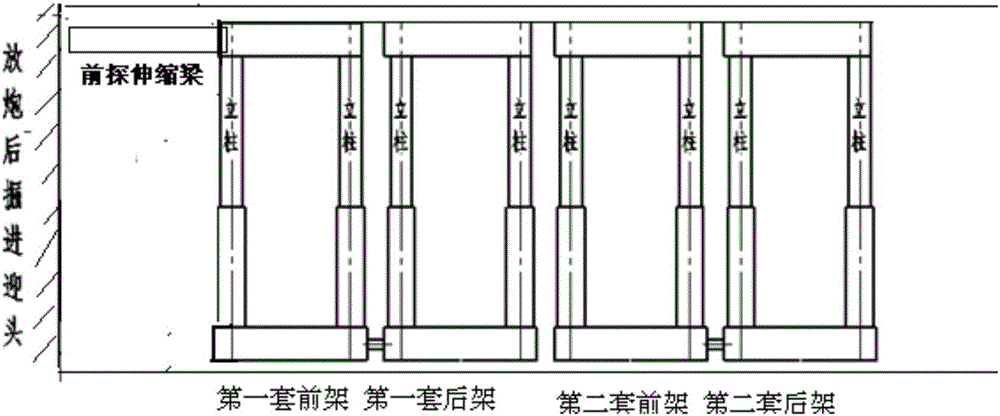

[0032] As shown in Figures 1-8, the telescopic top beam-supported temporary support method of the excavation face of the present invention is realized by a temporary support support, and the temporary support support includes a four-column front frame and a four-column rear frame , two moving jacks and a hydraulic system, the front frame and the rear frame are composed of four telescopic hydraulic columns, two bases and a top beam; the top beam includes two beams and several longitudinal beams, and hydraulic sleeves are arranged in the longitudinal beams Type stretching and shrinking beam; through the operation of the hydraulic system, the lifting of the hydraulic column, the telescopic jack and the expansion and contraction of the telescopic beam are realized, thereby realizing the temporary support and cyclic forward movement of the excavation roadway; it is characterized in that;

[0033] The two moving jacks of the temporary support bracket are respectively arranged in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com