Assembled active powder concrete box girder and its construction method

A concrete box girder and active powder technology, applied in bridges, bridge materials, bridge construction, etc., can solve the problems of high construction technology requirements, material self-heavy, high equipment conditions, etc., to achieve easy quality control, broad application prospects, and construction The effect of shaking is convenient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in combination with specific embodiments.

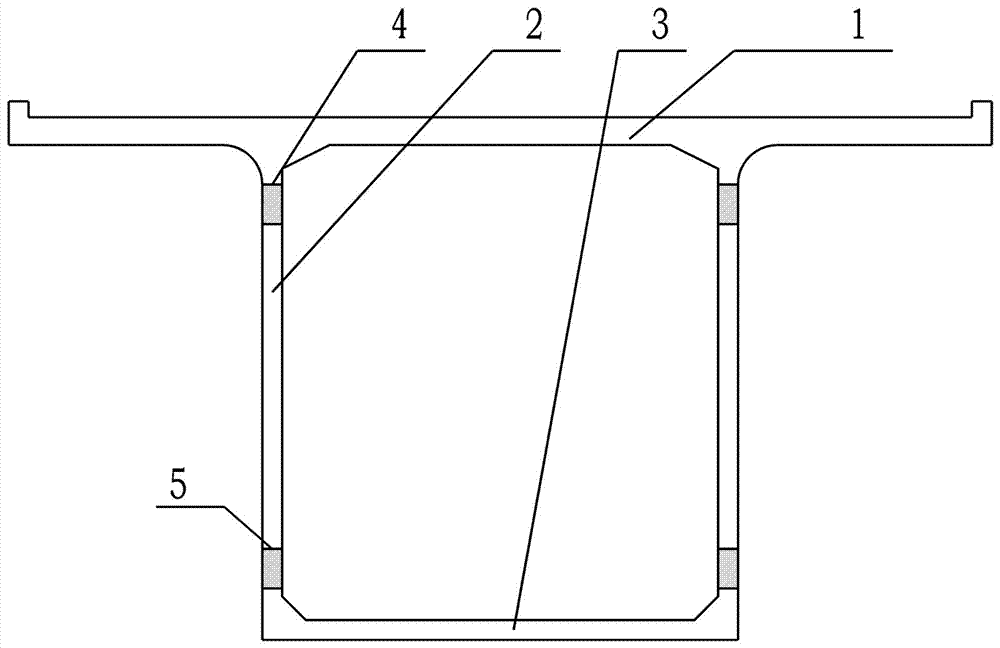

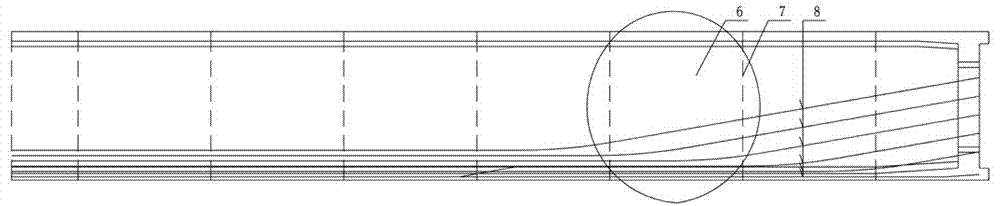

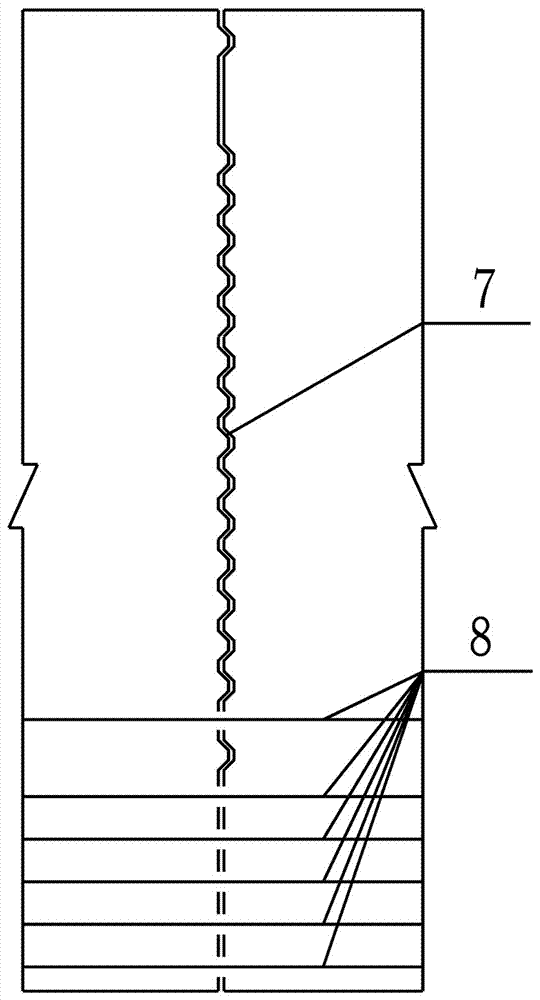

[0028] The assembled active powder concrete box girder of the present invention is composed of multiple prefabricated segments 6 spliced longitudinally. The prefabricated segment 6 includes a π-shaped top plate 1 at the top, a π-shaped bottom plate 3 at the bottom, and two webs 2 on both sides between the two, all of which are made of active powder concrete materials.

[0029] The connection between the π-shaped bottom plate 3 and the web 2 is the cast-in-place active powder concrete node 5 between the bottom plate and the web, and the left and right sides are symmetrically arranged; the connection between the π-shaped top plate 1 and the web 2 is the top plate and the web The cast-in-place reactive powder concrete nodes 4 are arranged symmetrically on the left and right sides; the π-shaped top plate 1, the π-shaped bottom plate 3 at the bottom, and the two webs 2 on bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com