Color-fixing method of natural colored silk

A colored silk and natural technology, which is applied in the field of color-fixing and value-added natural colored silk products, can solve the problems of fabric yellowing, toxicity, environmental protection and safety of colored silk, and achieve soft and bright colors, consistent colors, and resistance to scouring And the effect of strong washing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1, a kind of fixing method of natural colored silk, carries out following steps successively:

[0036] 1), preparation of fixation solution

[0037] Prepare a THPS solution with a concentration of 0.1 g / L, adjust the pH to 11.7 with a sodium hydroxide solution with a concentration of 0.1 mol / L, and heat the color-fixing solution to 75°C.

[0038] 2), solid color

[0039] Immerse the natural colored silk in the color-fixing solution at 75°C for 60 seconds at a bath ratio of 1:30 (mass-volume ratio, kg / L), take it out, then cool it for 20 hours, wash it thoroughly with clean water, and dry it at 70°C After 10 minutes, the solid color silk was obtained.

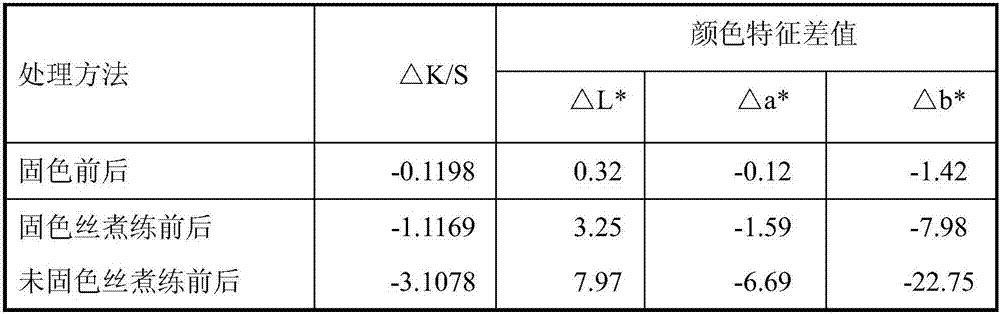

[0040] Experiment 1,

[0041] 1), scouring treatment

[0042] Unfixed and color-fixed colored silk (obtained in Example 1 above) is scoured in 0.2g / L sodium carbonate solution at 100°C for 0.5 hours at a bath ratio of 1:30 (mass volume ratio, kg / L) , take it out and wash it thoroughly with water and then d...

Embodiment 2

[0055] Prepare a THPS solution with a concentration of 50g / L and use a sodium hydroxide solution with a concentration of 2mol / L to adjust the pH to 5, with a bath ratio of 1:30 (kg / L), soak it at 7°C for 30 seconds, take it out, and place it in a cold stack for 36 Hour. Afterwards, fully wash with clear water, and bake at 100° C. for 1 minute to obtain solid-color dyed silk. Other steps are the same as in Example 1.

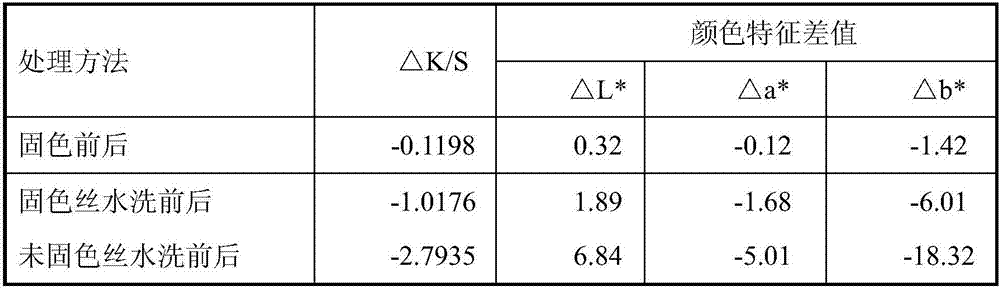

[0056] Then, the test was carried out as in Experiment 1, and the analysis results were as follows:

[0057] Table 3 shows the color difference between fixed and unfixed colored silk after scouring, and Table 4 shows the color difference between fixed and unfixed colored silk after 10 times of washing. Compared with fixed color silk, the degree of fading after scouring / washing treatment is significantly reduced, and a better color fixing effect is achieved. At the same time, repeated (at least 3) experiments were carried out in this experiment, and similar resu...

Embodiment 3

[0066] Prepare a THPS solution with a concentration of 450g / L and adjust the pH to 2.5 with a sodium hydroxide solution with a concentration of 0.5mol / L, with a bath ratio of 1:30 (kg / L), soak at 20°C for 1 second, and then place it in a cold stack for 5 hours . Afterwards, rinse thoroughly with clean water, and bake at 120°C for 30 seconds to obtain solid-color colored silk. Other steps are with embodiment 1.

[0067] Then, the test was carried out as in Experiment 1, and the analysis results were as follows:

[0068] Table 5 shows the color difference of fixed and unfixed silk after scouring, and Table 6 shows the color difference of fixed and unfixed silk after 10 times of washing. Under the above conditions, THPS can reach a certain level. color fixing effect. At the same time, repeated (at least 3) experiments were carried out in this experiment, and similar results can be obtained.

[0069] Table 5. Color difference between fixed and unfixed silk after scouring

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com