Production method for yellow wine lee rice wine

A production method and technology of rice distiller's grains, which are applied in the preparation of alcoholic beverages and other directions, can solve the problems that no one has implemented yet, and achieve the effects of rich amino acid content, balanced amino acid content, and sweet and soft taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

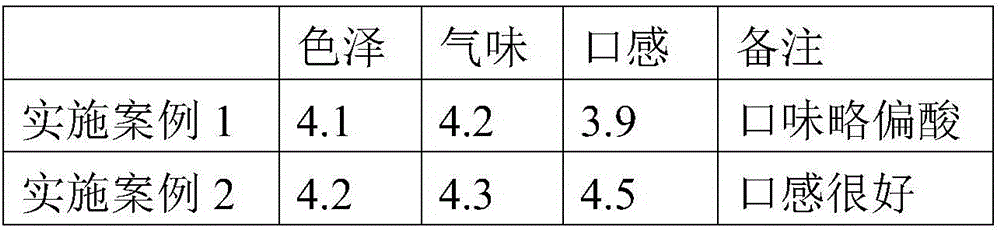

Embodiment 1

[0022] Soak the glutinous rice in water at 0°C to 10°C for 14d to 15d, drain the water, steam the glutinous rice for 10min to 30min to obtain steamed glutinous rice; cool the steamed glutinous rice to 30°C to 35°C.

[0023] After pulverizing 30-50 parts by weight of rice wine distiller's grains, add 50-70 parts by weight of hot water at 35° C. to the rice wine distiller's grains and stir evenly.

[0024] Get 1kg of steamed glutinous rice and drop it into the cylinder (the method of spreading rice), when the temperature of the rice drops to 25-28°C, add 1kg of rice wine distiller's grains, 8g of sweet wine koji, 1g of glucoamylase and 1g of protease for wine by weight, Mix evenly; after the saccharification stage and the fermentation stage, the fermented product is taken out, left to stand for 24 hours, clarified, filtered, and sterilized to obtain yellow distiller's grain rice wine. The saccharification stage is: saccharification at 35°C-36°C for 10h-20h, the first raking; sac...

Embodiment 2

[0026] Soak the glutinous rice in water at 0°C to 10°C for 14d to 15d, drain the water, steam the glutinous rice for 10min to 30min to obtain steamed glutinous rice; cool the steamed glutinous rice to 30°C to 35°C.

[0027] After pulverizing 30-50 parts by weight of rice wine distiller's grains, add 50-70 parts by weight of hot water at 35° C. to the rice wine distiller's grains and stir evenly.

[0028] Get 1kg of steamed glutinous rice and drop it into the cylinder (rice spreading method). When the temperature of the rice drops to 25-28°C, add 0.5kg of rice wine distiller's grains, 8g of sweet wine koji by mass, 1g of glucoamylase and 1g of wine by weight. Mix evenly with protease; after the saccharification stage and the fermentation stage, take out the fermented product, let it stand for 24 hours, then clarify, filter, and sterilize to obtain yellow distiller's grains rice wine. The saccharification stage is: saccharification at 35°C-36°C for 10h-20h, the first raking; sac...

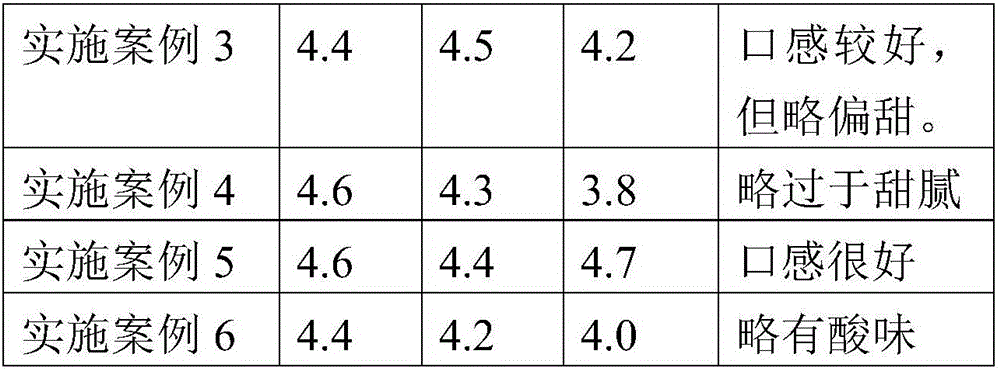

Embodiment 3

[0030] Soak the glutinous rice in water at 0°C to 10°C for 14d to 15d, drain the water, steam the glutinous rice for 10min to 30min to obtain steamed glutinous rice; cool the steamed glutinous rice to 30°C to 35°C.

[0031] After pulverizing 30-50 parts by weight of rice wine distiller's grains, add 50-70 parts by weight of hot water at 35° C. to the rice wine distiller's grains and stir evenly.

[0032] Get 1kg of steamed glutinous rice and drop it into the cylinder (rice spreading method), when the rice temperature drops to 25-28°C, add 0.33kg of rice wine distiller's grains, 8g of sweet wine koji, 1g of glucoamylase and 1g of protease for wine , mixed evenly; after the saccharification stage and the fermentation stage, the fermented fermented product was taken out, left to stand for 24 hours, clarified, filtered, and sterilized to obtain yellow distiller's grain rice wine. The saccharification stage is as follows: saccharification at 35°C to 36°C for 10h to 20h, the first r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com