Water-soluble thin film with good water dissolving performance and small bag prepared from water-soluble thin film

A water-soluble film, water-dissolving technology, applied in the direction of bags, sacks, flexible containers, etc., can solve problems such as easy residues, and achieve the effect of good stability and good water-soluble performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

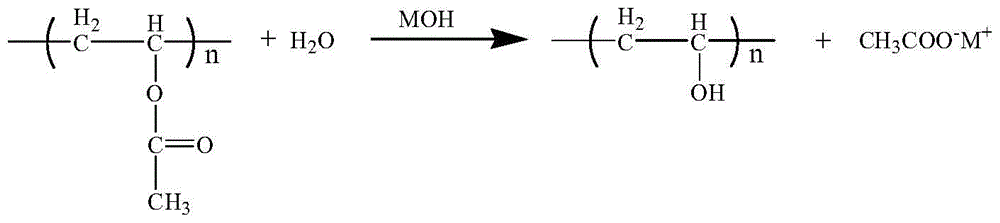

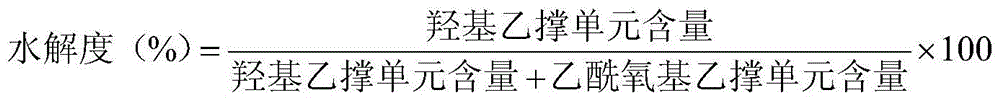

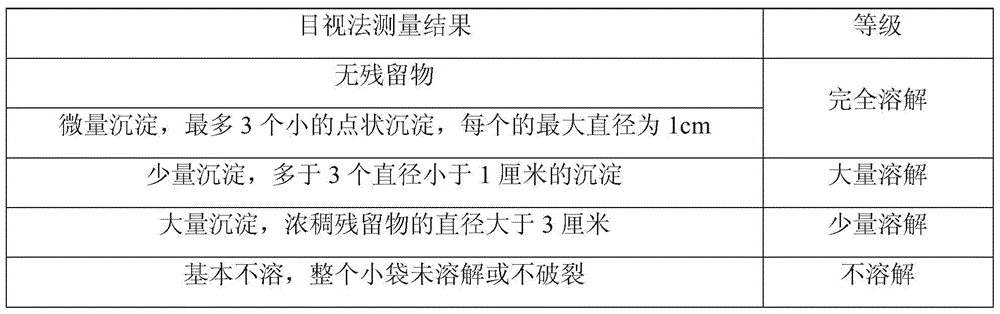

Method used

Image

Examples

preparation example Construction

[0107] Method of making the sachet

[0108] In the examples, sachets were made according to the following method:

[0109] 1) Firstly, the bottom layer film is heated on the heating roller, and the heating temperature is 30-50°C.

[0110] 2) Use a vacuum to suck the bottom film into an appropriate mold, and when the film fits the mold, fill the liquid content into the mold, and the amount of addition can be adjusted according to the size of the mold.

[0111] 3) The surface film and the bottom film are sealed by heat sealing or wet sealing. Water is preferably applied to the upper membrane surface and pressure is then applied to the seal area to form a seal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com