Silylated polyarylene

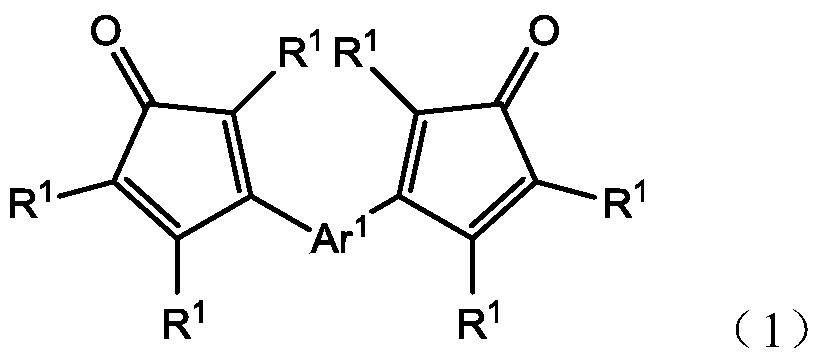

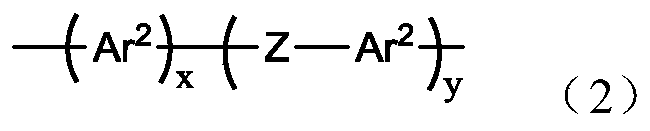

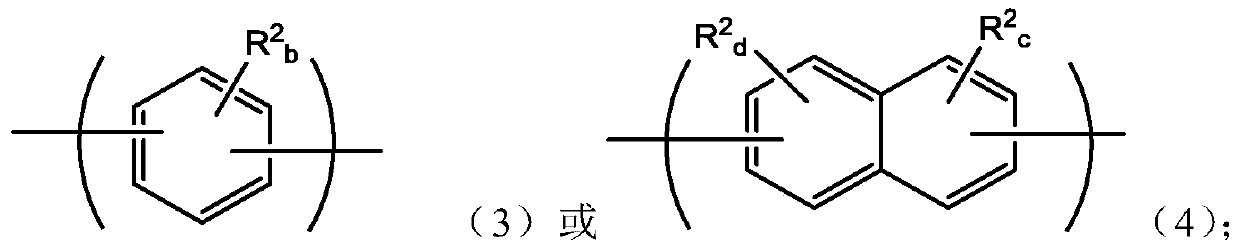

An arylene and aryl technology, applied in the field of polyarylene materials, can solve problems such as incompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0036] Example 1: To a multi-neck round bottom flask with a stir bar was added via a powder funnel diphenylene oxide bis(triphenylcyclopentadienone) (DPO-CPD, 2.75 g, 3.52 mmol) followed by alkyne monomer 1, 3-Bis[(trimethylsilyl)ethynyl]benzene (1,3-TMS-DEB, 1.00 g, 3.70 mmol) and reaction solvent γ-butyrolactone (GBL, 20 g, 16% solids). The reaction was stirred gently at room temperature to obtain a homogeneous mixture. The flask was then equipped with a reflux condenser and an internal thermocouple probe attached to a self-regulating thermostat attached to a heating mantle. The dark maroon contents of the flask were warmed to an internal temperature of 205°C and maintained at this temperature for 96 hours, then cooled to room temperature by removing the heating element. The resulting dark maroon solution was transferred to a vial. Gel permeation chromatography on this crude mixture reveals that M n = 5362 Da and M w = Peak molecular weight distribution of 6678 Da.

[...

example 2

[0040] Example 2: The procedure of Example 1 was repeated except that the solvent was benzyl propionate.

example 3

[0041] Example 3: To a multi-neck round bottom flask with a stir bar was added diphenylene oxide bis(triphenylcyclopentadienone) (2.75 g, 3.52 mmol) followed by 1,3-bis[(trimethoxy silyl)ethynyl]benzene (1.36 g, 3.72 mmol) and the reaction solvent N-methylpyrrolidone (25 g). The reaction was stirred gently at room temperature to obtain a homogeneous mixture. The flask was then equipped with a reflux condenser and an internal thermocouple probe attached to a self-regulating thermostat attached to a heating mantle. The contents of the flask were warmed to an internal temperature of 195°C and maintained at this temperature for 96 hours before the heating element was removed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com