Reactive distillation method and device for 4emd production

A technology of reactive distillation and reactive distillation column, which is applied in the field of reactive distillation methods and devices produced by 4EMD, can solve the problems such as difficulty in breaking through the reaction equilibrium for single-pass conversion rate, unsuitable for large-scale industrial applications, and complicated operation streams. , to achieve the effect of saving equipment investment, reducing energy consumption, and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

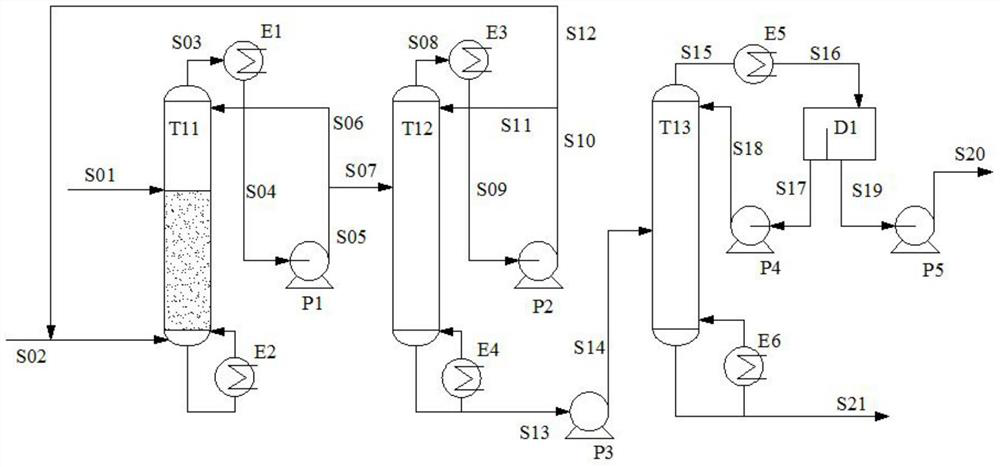

[0030] The method of the present invention is used for 1,2-butanediol acetal reaction and prepares the production process of 4EMD, as figure 1 As shown, the feed 1,2-butanediol and acetaldehyde are raw materials of considerable purity, the processing capacity of 1,2-butanediol is 45kg / hr, the amount of acetaldehyde used in the reactive distillation column and the quality of butanediol The ratio is 0.59. The total number of theoretical plates in the reactive distillation column is 22, and the 7th to 22nd stages are the reactive distillation section. The macroporous acidic cationic resin (NKC-9) is used as the catalyst. The operating pressure is 0.5atm by absolute pressure, the reflux ratio is 0.15, and the top control Extract the content of butanediol. The total number of theoretical plates of the acetaldehyde recovery tower is 20, the operating pressure is 2 atm in terms of absolute pressure, the reflux ratio is 1.7, and the purity of acetaldehyde is controlled at the top of ...

Embodiment 2

[0033] The method of the present invention is used for 1,2-butanediol acetal reaction and prepares the production process of 4EMD, as figure 1 As shown, the processing capacity of feed 1,2-butanediol is 1000kg / hr, the water content of acetaldehyde is 10w%, and the ratio of the molar amount of acetaldehyde entering the reactive distillation column to the molar amount of butanediol is maintained at 1.2. Other operating conditions are also shown in Example 1.

[0034] After the above-mentioned process, the mass purity of the product 4EMD is as high as 99.9%, and the recovery rate can reach 97.6%.

Embodiment 3

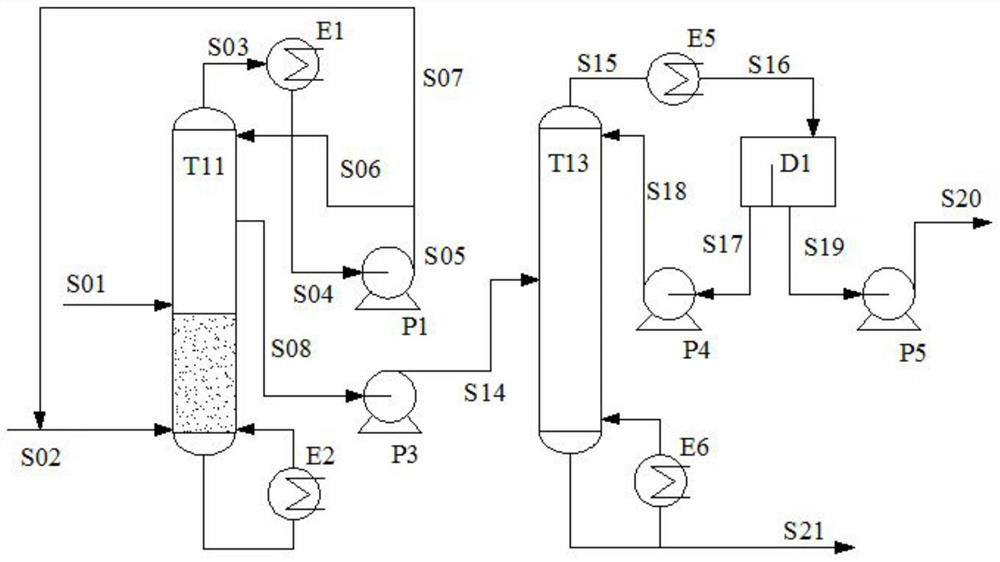

[0036] The method of the present invention is used for 1,2-butanediol acetal reaction and prepares the production process of 4EMD, as figure 2 As shown, the feed 1,2-butanediol and acetaldehyde are raw materials of considerable purity, the processing capacity of 1,2-butanediol is 200kg / hr, the amount of acetaldehyde used in the reactive distillation column and the quality of butanediol The ratio is 0.60. The total number of theoretical plates of the reactive distillation column is 30, and the 16th to 30th grades are the reactive distillation section. Strong acidic molecular sieves (macroporous acidic cationic resin NKC-9) are used as catalysts. The operating pressure is absolute pressure as normal pressure, and the reflux ratio is 16. The 15th theoretical plate of the butanediol stream is fed, and the reaction product is withdrawn from the side line at the 11th theoretical plate, and the purity of acetaldehyde is controlled at the top of the tower for recycling. The mixture ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com