Shear-fork type insulation overhead work platform car

A technology of aerial work platforms and scissors, which is applied in the direction of lifting frames and lifting devices, can solve problems such as low efficiency, increased maintenance, and difficulty in adapting to achieve the effect of improving work efficiency and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

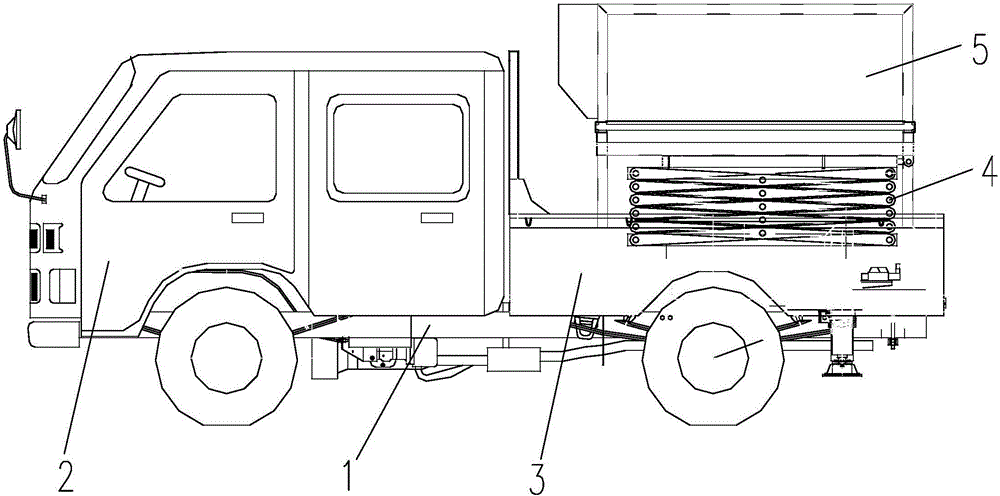

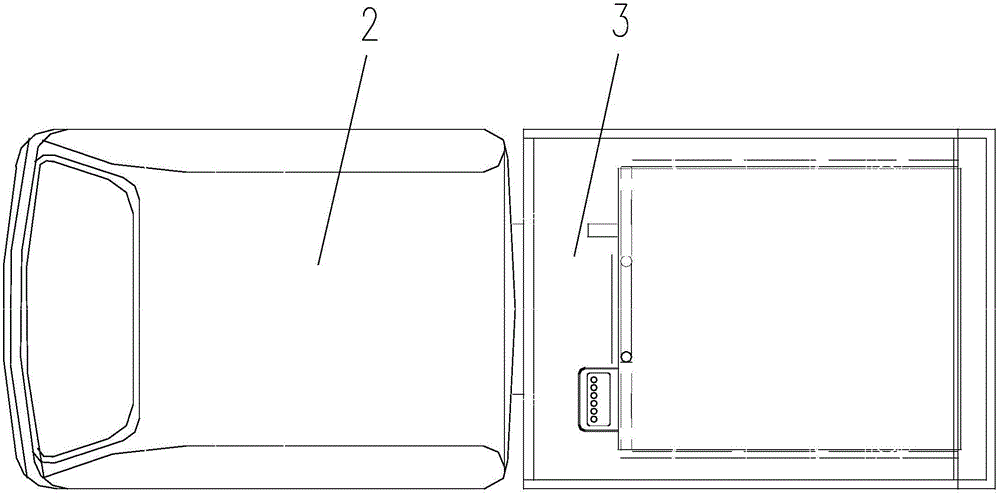

[0034] The present invention as Figure 1-12 As shown, a car body 1 is included, the car body is provided with a headstock 2 and a carriage 3, and a platform assembly 5 connected by a scissor mechanism 4 is provided in the carriage,

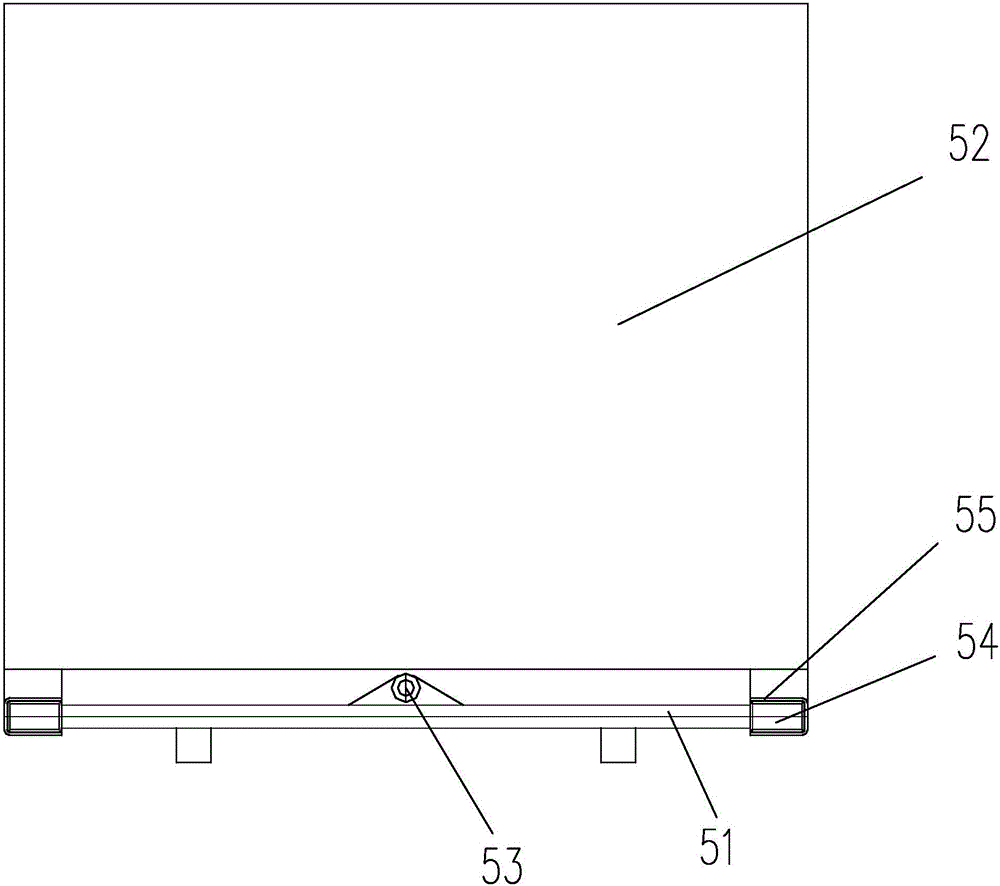

[0035] The platform assembly 5 includes a bracket 51, a surrounding platform 52 and a push cylinder 53, the bracket 51 and the surrounding platform 52 are made of glass fiber reinforced plastics, a pair of guide rails 54 are arranged on both sides of the bracket 51, and the surrounding platform A pair of guide sleeves 54 are provided on both sides of the bottom surface of 52, and the guide sleeves are fitly sleeved on the guide rails. The push cylinder 53 is located between the surrounding platform 52 and the bracket 51. The cylinder body of the push cylinder It is arranged on the bracket, and the hydraulic rod that pushes the oil cylinder is connected to the surrounding platform, so that the horizontal platform can move horizontally and is arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com