Stable winding method and winding mechanism of rewinder

A rewinding machine, a stable technology, applied in the field of rewinding machines, can solve the problems of difficult paper head rewinding reliably, increasing the manufacturing cost of rewinding machine and equipment debugging difficulty, rewinding failure and other problems, so as to reduce the selection and processing technology Requirements, reduce manufacturing cost and equipment debugging difficulty, improve the effect of reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

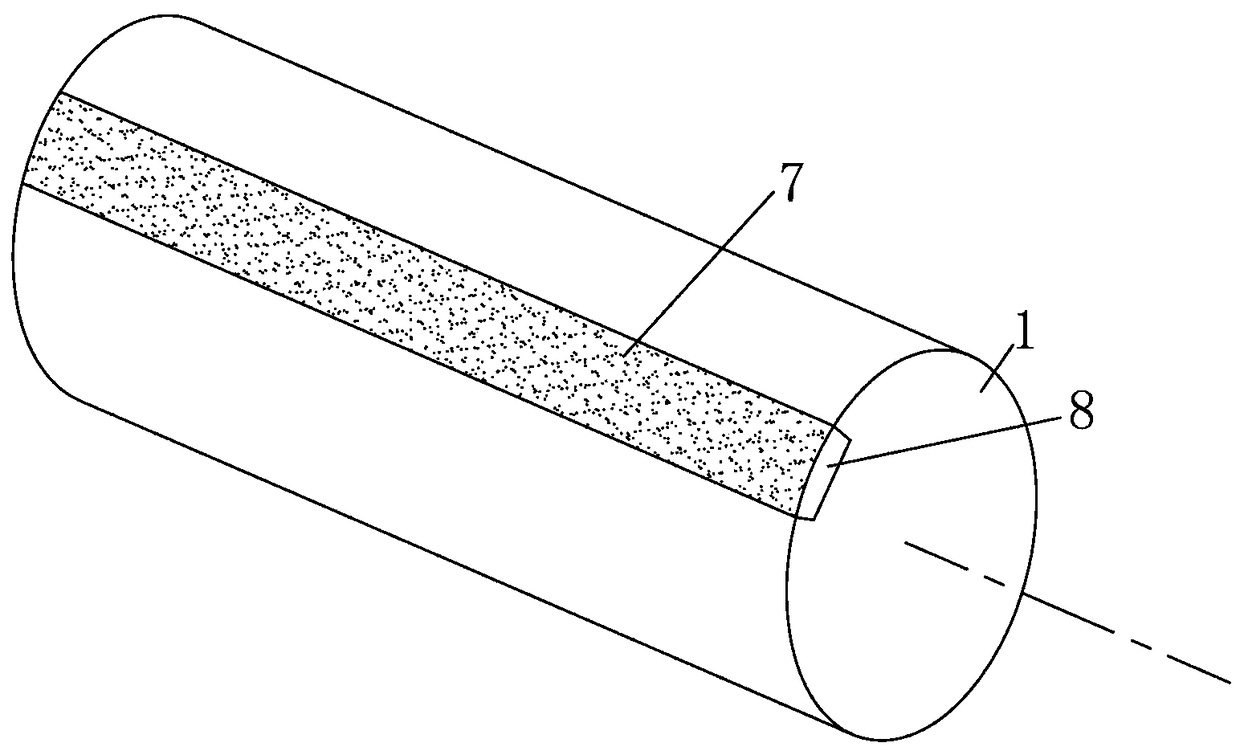

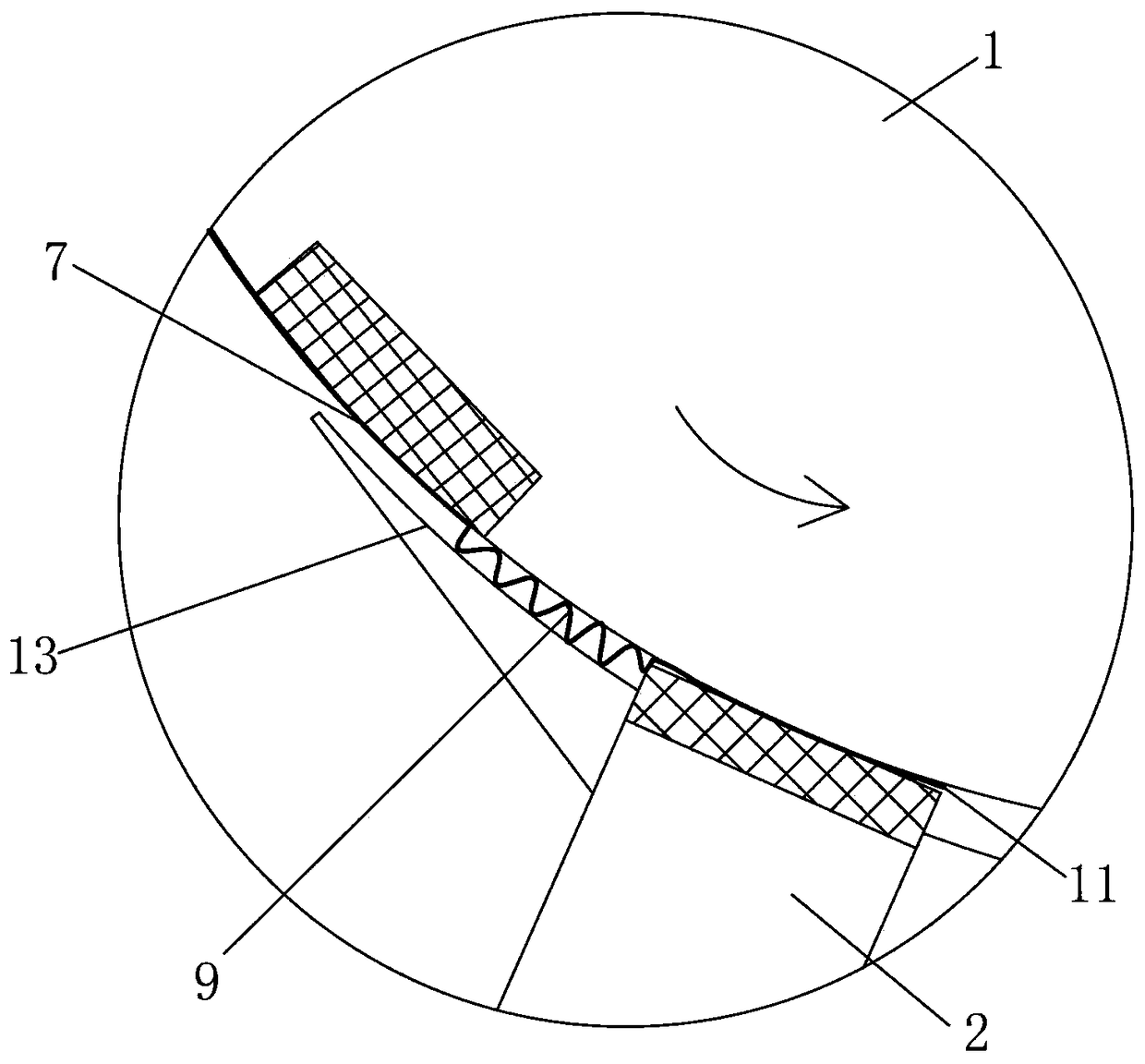

[0021] see figure 1 , according to the stable winding mechanism of the rewinding machine according to the present invention, it includes a rewinding upper roller 1 and a moving part 2 . When rolling up, the moving part 2 rotates around the axis 3, and can be as figure 2 In that way, it leans against the roll surface of the rewinding upper roll 1. In addition to the winding mechanism, figure 1 The rewinding lower roller 4 and the paper pressing roller 5 of the rewinding machine are also drawn, and a curved surface 13, the curved surface 13 is close to the rewinding upper roller 1 to form a paper roll passage 6. A local rough surface 7 is provided on the roll surface of the rewinding upper roll 1 . Such as image 3 As shown, the local rough surface 7 forms a narrow strip-shaped rough texture parallel to the axis of the rewind upper roll 1 on the roll surface of the rewind upper roll 1, and the entire local rough surface 7 is an inlaid block on the roll surface 8 on the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com