Non-core paper roll rewinding machine utilizing circulation belt for winding

An endless belt and rewinder technology, applied in the field of rewinders, can solve the problems of difficulty in realizing high-speed rewinding, unsteady rewinding, and difficult control, and achieve easy high-speed rewinding, stable rewinding, and low control difficulty. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

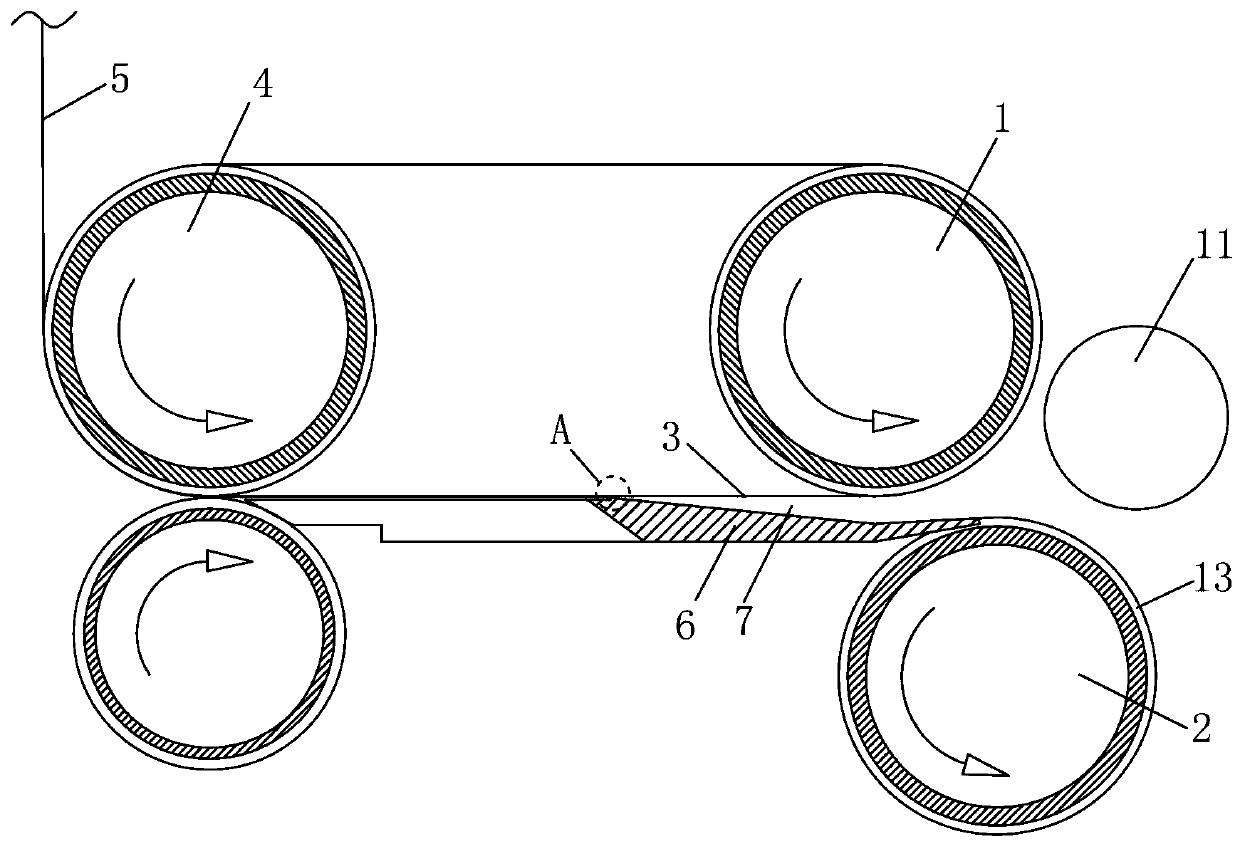

[0024] see figure 1 , The coreless paper roll rewinding machine of the present invention is provided with a rewinding upper roll 1 and a rewinding lower roll 2, and an endless belt 3 for pulling paper. One end of the endless belt 3 is wound on the rewinding upper roller 1 , and the other end is wound on the tension pulley 4 . The tensioning pulley 4 tensions the endless belt 3 . The paper 5 used for rewinding into paper rolls winds around the tension wheel 4 and sticks to the belt surface of the endless belt 3 . A roll-assisting plate 6 is provided at a position close to the endless belt 3 , and a roll-up passage 7 is formed between the rolled-aid plate 6 and the endless belt 3 . Circulation belt 3 can adopt belt.

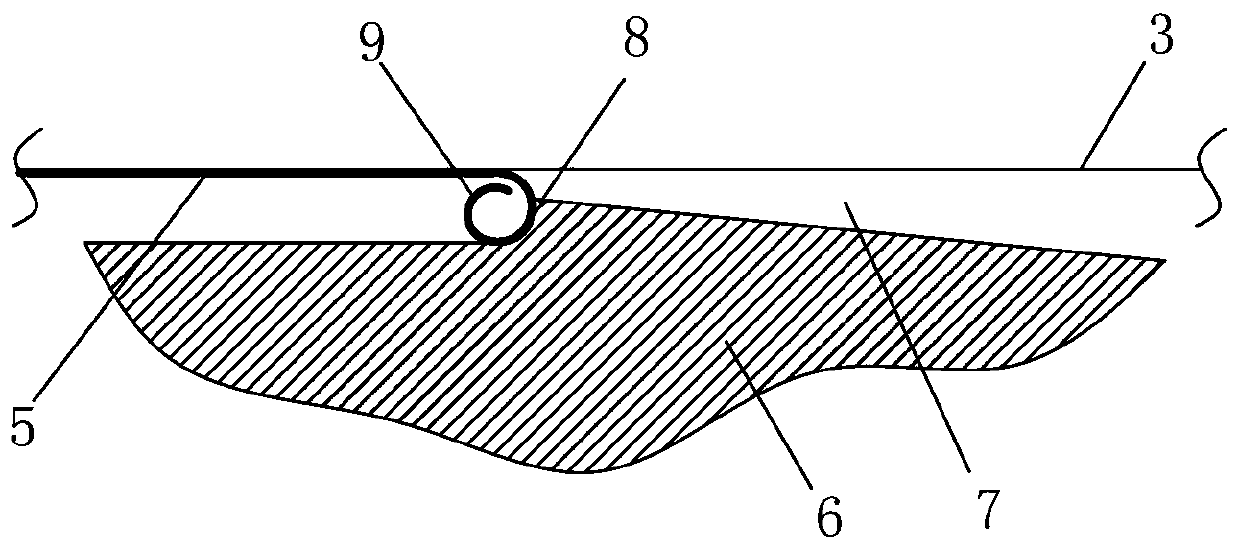

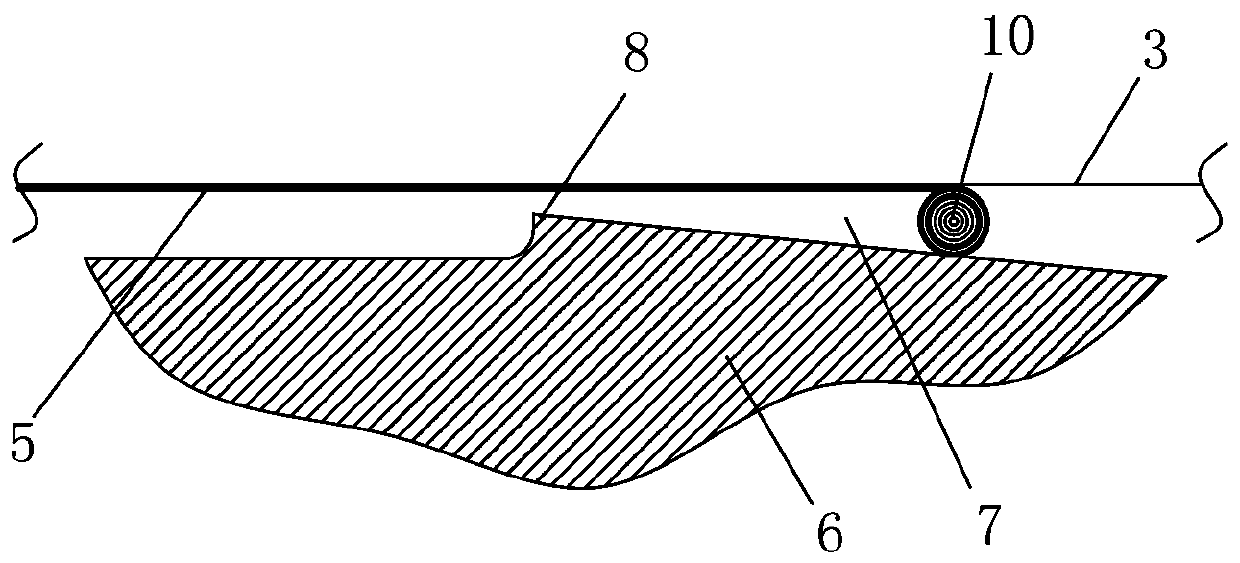

[0025] see also figure 1 , figure 2 The rolling aid plate 6 is provided with a flange 8 protruding toward the endless belt 3, and the height of the flange 8 is preferably not greater than 3 mm. The gap between the flange 8 and the endless belt 3 is small eno...

Embodiment 2

[0029] see Figure 6 In this embodiment, a liner 14 is added on the basis of the first embodiment. The liner 14 is located on the other side of the endless belt 3 relative to the rolling-assisting plate 6 , and the liner 14 abuts against the endless belt 3 . The backing plate 14 ensures that the gap between the endless belt 3 and the flange 8 of the rolling aid plate 6 will not become larger due to the elastic deformation of the endless belt 3, which improves the reliability of rolling.

Embodiment 3

[0031] see Figure 7 , In this embodiment, on the basis of Embodiment 1, a paper pressing movable part 15 is added. During the process of rewinding the paper 5 into a paper roll, the paper pressing movable member 15 does not contact the paper 5 . when Figure 7 When the rewinding of a roll of paper roll 16 shown is completed, the paper pressing movable part 15 rotates one revolution. When the platen movable part 15 rotates to Figure 7 Moment at the position shown, as Figure 8 As shown, the paper pressing movable member 15 presses the paper 5 drawn by the endless belt 3 against the endless belt 3 , thereby hindering the advancement of the paper 5 , so that the paper 5 is stretched and broken. After paper 5 is broken, Figure 7 The shown paper roll 16 rolls out from the nip between the rewinding upper roller 1, the rewinding lower roller 2 and the platen roller 11, and at the same time, the fracture of the paper 5 becomes Figure 8 Paper tip 9 shown. When the newly form...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com