Winding mechanism for gravure printing machine

A technology of winding mechanism and printing machine, applied in gravure rotary printing machine, printing machine, rotary printing machine, etc., can solve the problems of easy creases, high production cost, complex structure, etc., and achieve convenient use, reasonable structure, The effect of high rewinding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

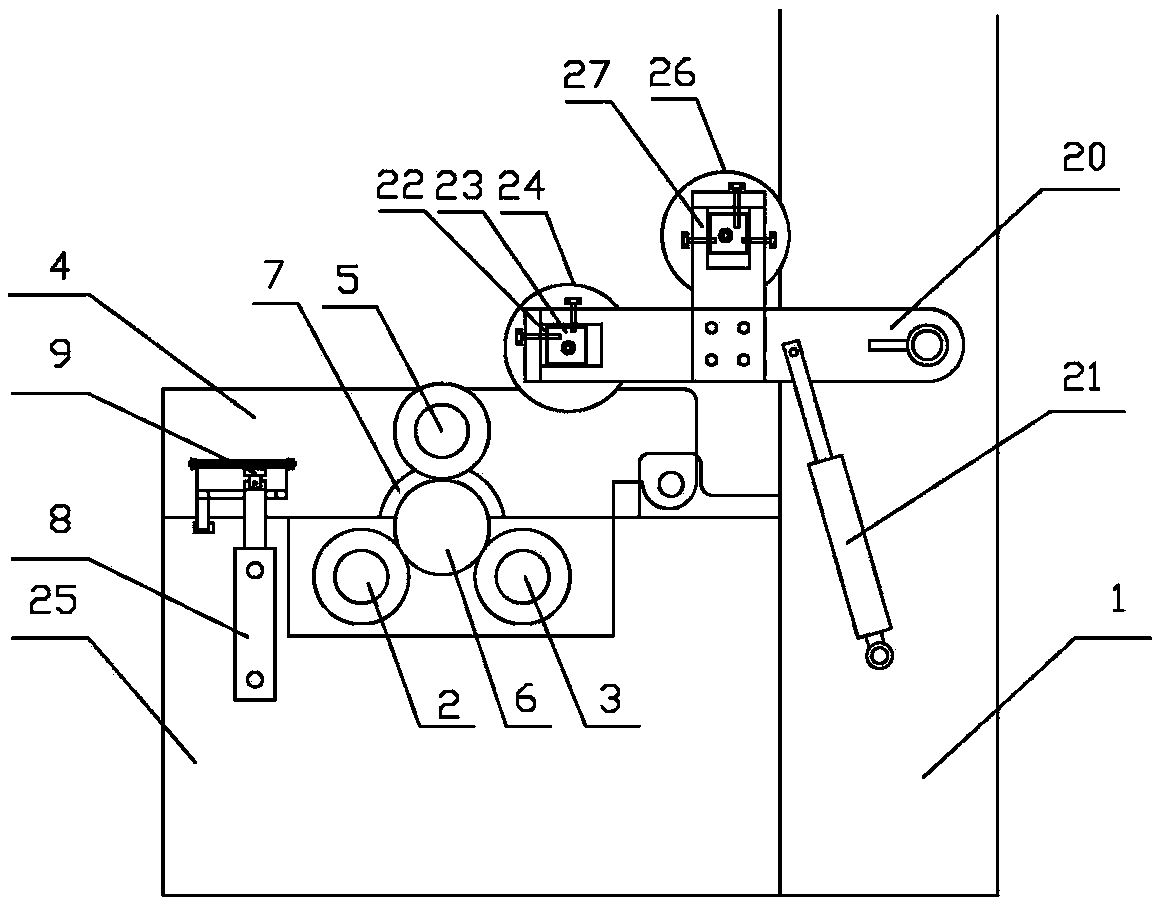

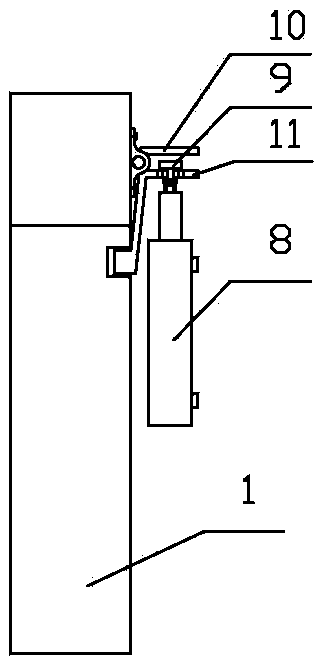

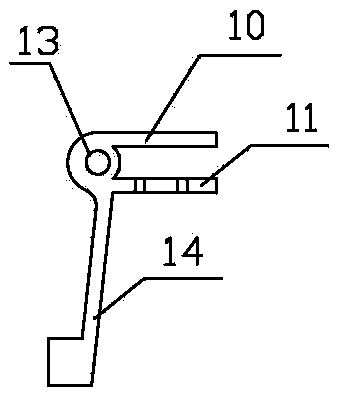

[0012] Such as figure 1 As shown, the winding mechanism for the gravure printing machine according to the present invention includes a frame 1, a swing arm 20 hinged on the frame 1 and a swing arm cylinder 21, and the swing arm cylinder 21 is located on the side of the swing arm 20 Below, the telescopic link of the swing arm cylinder 21 is hinged on the swing arm 20, and the swing arm cylinder 21 can be pushed to swing up and down when the swing arm cylinder 21 works. The end of swing arm 20 is provided with square hole 22, and rectangular slide block 23 is installed in described square hole 22, and described rectangular slide block 23 has at least two sides to be connected on the hole wall of square hole 22 by bolt, guides The end of the paper roll 24 is inserted on the rectangular slider 23 through a bearing. The position of the rectangular slider 23 can be fine-tuned by adjusting the bolts arranged on the hole wall of the square hole 22, thereby adjusting the levelness of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com