Automatic conveying system and method for car body coating auxiliary tools

An auxiliary tooling and automatic conveying technology, which is applied in the direction of conveyors, mechanical conveyors, transportation and packaging, etc., can solve the problems of affecting production rhythm, waste of manpower, inaccurate transfer methods and automatic distribution, so as to save manpower and improve production Efficiency and the effect of improving equipment utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The specific implementation manner of the present invention will be described in further detail below by describing the best embodiment with reference to the accompanying drawings.

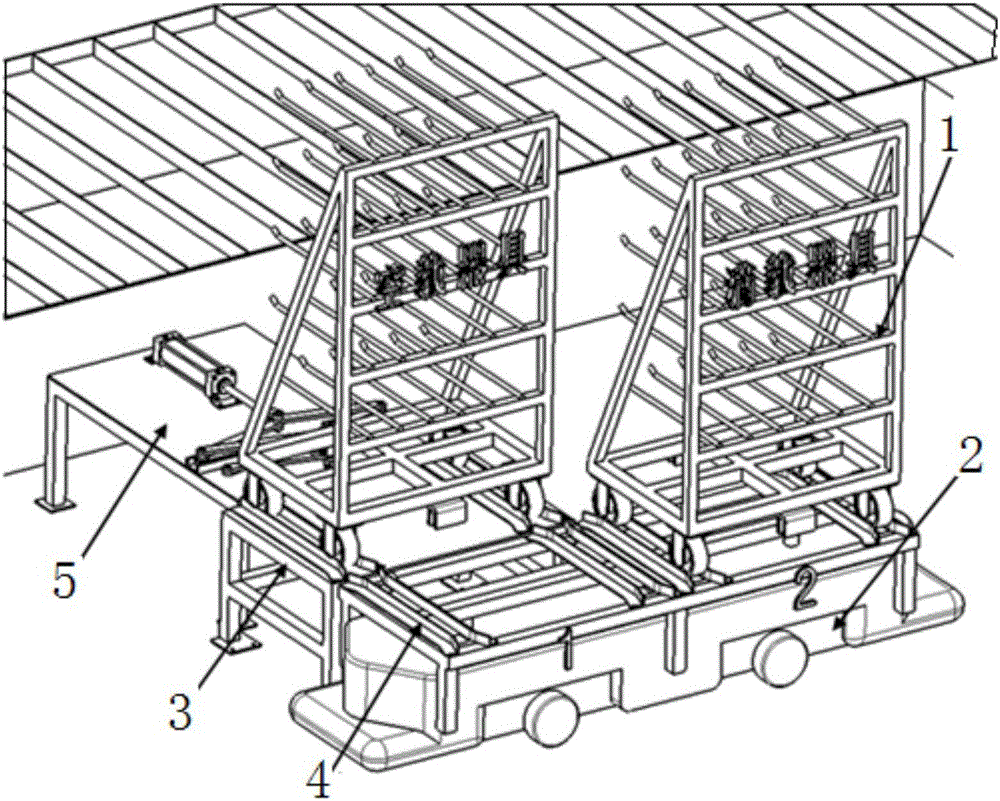

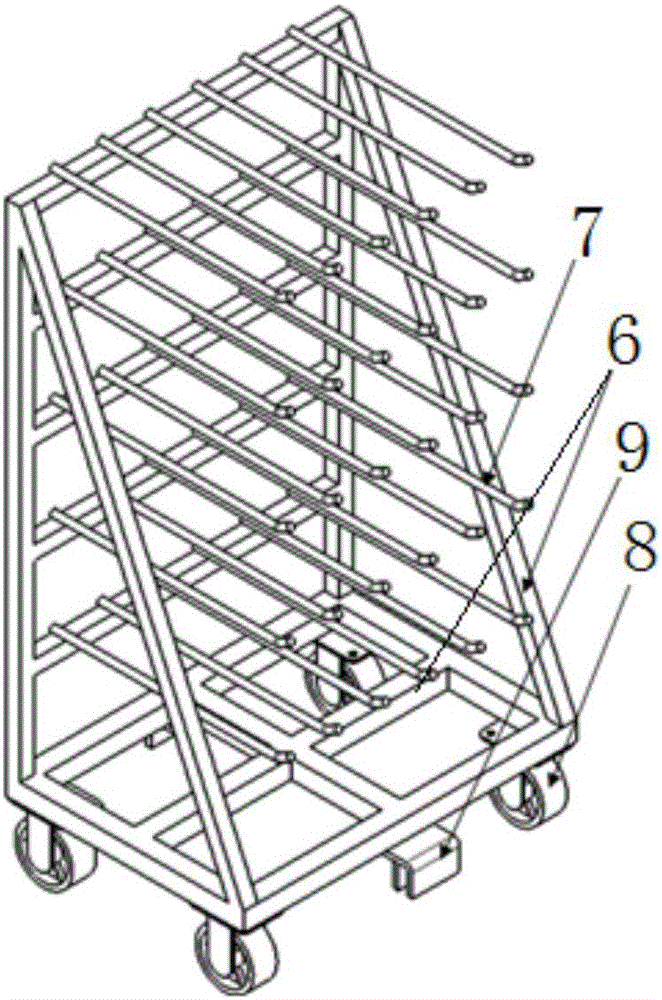

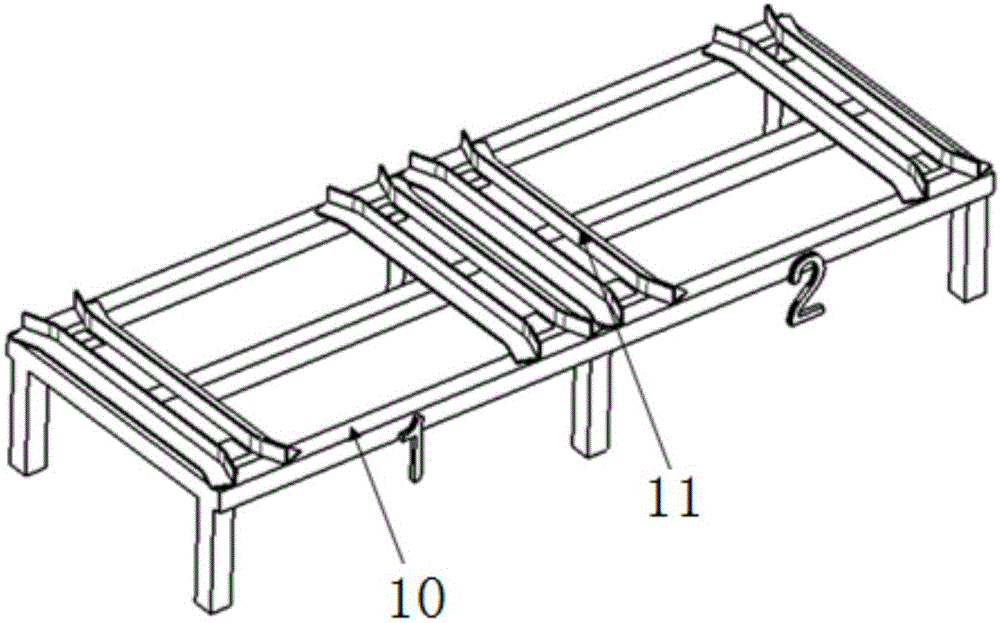

[0033] Such as figure 1 As shown, the automatic conveying system for auxiliary tooling for body painting includes a tooling rack 1 for loading auxiliary tooling for painting and an AGV trolley 2. A pallet 4 for transporting the tooling rack 1 is provided on the AGV trolley 2, and it also includes a The edge of the production line is used to unload and load the automatic docking mechanism 5 of the tooling rack 1 and the line edge workbench 3 docked with the pallet 4 to place the unloaded tooling rack 1 . The tooling rack 1 is used to store the auxiliary tooling for body painting; the AGV trolley 2 is an automatic unmanned operation equipment, which is used to transport the auxiliary tooling of the body, and can automatically and accurately transport the auxiliary tooling to the designated po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com