Combined integrated fuel tank

A fuel tank and integrated technology, which is applied in the field of auto parts, can solve the problems of large space occupation of the car body and high difficulty of assembly, and achieve the effects of increasing auxiliary fuel tanks, saving chassis space, and saving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

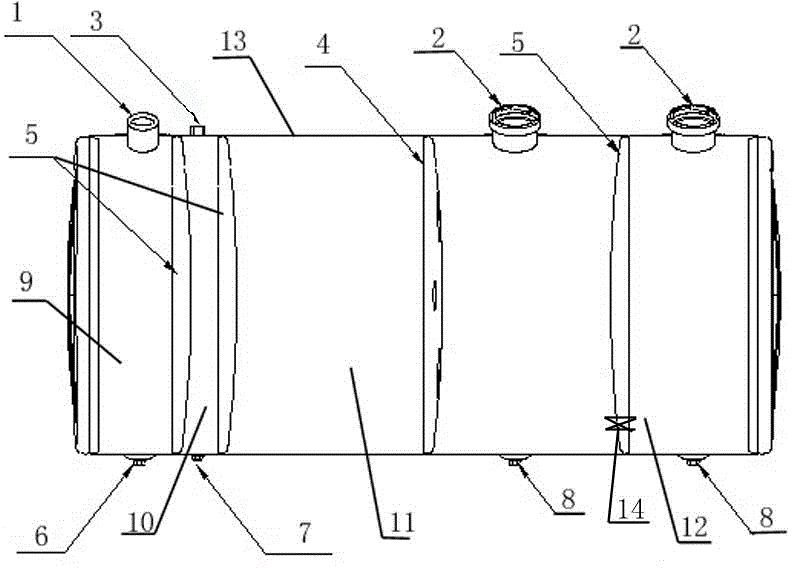

[0021] The present invention as figure 1 shown.

[0022] This fuel tank is a four-box large-capacity fuel tank that integrates a composite double-chamber fuel tank, a urea tank, and a heating tank, developed according to the background of domestic long-distance transportation and different use environments. , saving space and increasing the fuel capacity of the vehicle.

[0023] The composite integrated fuel tank includes the fuel tank body 13, and the fuel tank body 13 is divided into four chambers by three non-porous partitions 5, namely the first chamber 9, the second chamber 10, and the third chamber 11, and the fourth chamber 12; wherein the first chamber 9 is a urea chamber, the second chamber 10 is a heating chamber, the third chamber 11 is a fuel tank, and the fourth chamber 12 is an auxiliary fuel tank; each chamber Both are equipped with inlets and outlets, which are respectively the urea filling port 1 and the urea discharge hole 6 of the first chamber 9, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com