Vortex tube-type membrane component and system

A tubular membrane and membrane module technology, applied in the field of membrane separation, can solve the problems of membrane damage, reduced service life, increased daily use cost, etc., to achieve the effect of eliminating thermal stress, low-cost operation, and realizing cost-effective operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The preferred embodiments of the present invention are described in detail below, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

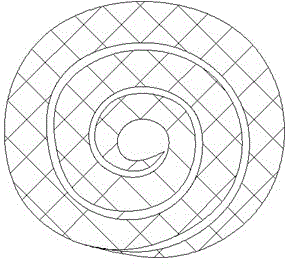

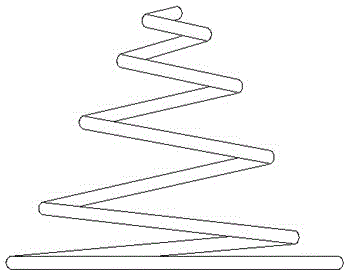

[0015] The present invention describes a vortex tube membrane module and system. The membrane module is composed of a vortex tube membrane element, a pipe and a casing, and is driven by a motor to rotate. The vortex tube membrane element is shaped For the vortex, spiral and tower spiral structure. The original solution flows inside the tube, and the permeate flows outside the tube.

[0016] The diameter of the vortex tubular membrane element is gradually changing, that is, the membrane passing conditions (pressure, tangential force, etc.) change with the change of the medium characteristic (concentration, viscosity, flow) parameters of the fluid.

[0017] When the flow channel of the vortex tub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com