A batching method of a new kitchen cabinet cabinet board batching system

A batching system and kitchen cabinet technology, which is applied in the batching field of the new kitchen cabinet cabinet board batching system, can solve the problems of affecting the production process, low efficiency, and batching errors, so as to improve production efficiency, high batching efficiency, and eliminate wrong batching Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further explained below in conjunction with the drawings:

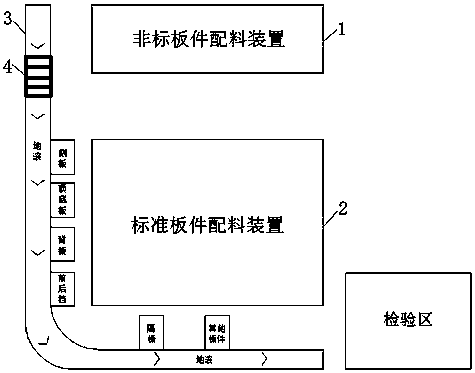

[0017] Such as figure 1 Shown is a new type of batching method for the kitchen cabinet box board batching system. The kitchen cabinet box board includes a standard board and a non-standard board; both the standard board and the non-standard board are provided with display Bar code or two-dimensional code of panel parameter information; the kitchen cabinet box body board batching system includes non-standard panel batching device 1, standard panel batching device 2, along non-standard panel batching device 1 and standard panel batching device 2 A ground roller 3 arranged on the outer circumference and a number of batching trolleys 4 arranged above the ground roller 3 and slidingly fitted with the ground roller 3; the non-standard plate batching device 1 includes a non-standard plate batching frame, which is embedded and installed on the non-standard plate A number of non-standard plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com