A smt production rhythm control system and its self-locking delay loop

A technology of control system and rhythm, applied in the direction of comprehensive factory control, electrical program control, comprehensive factory control, etc., can solve the problems of easy chemical reaction with oxygen in the air, brittle contact, affecting welding effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings.

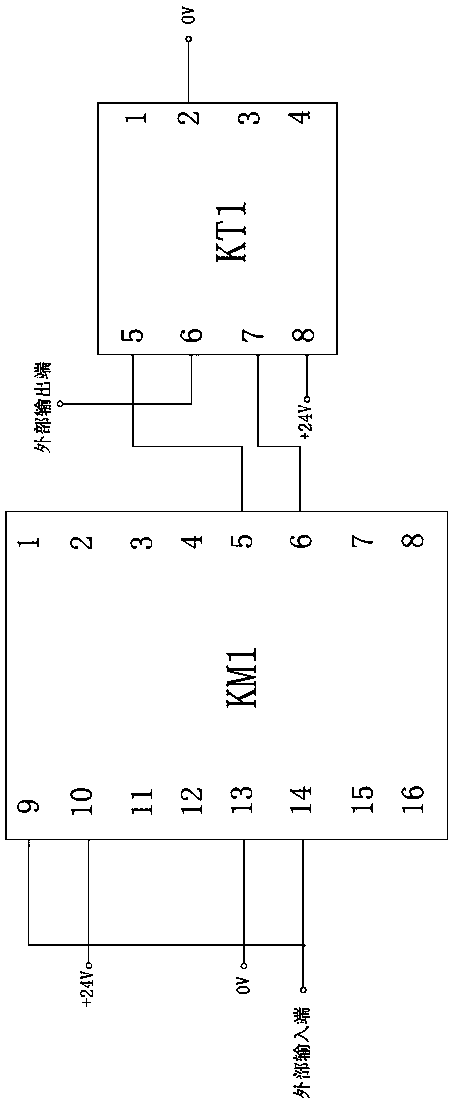

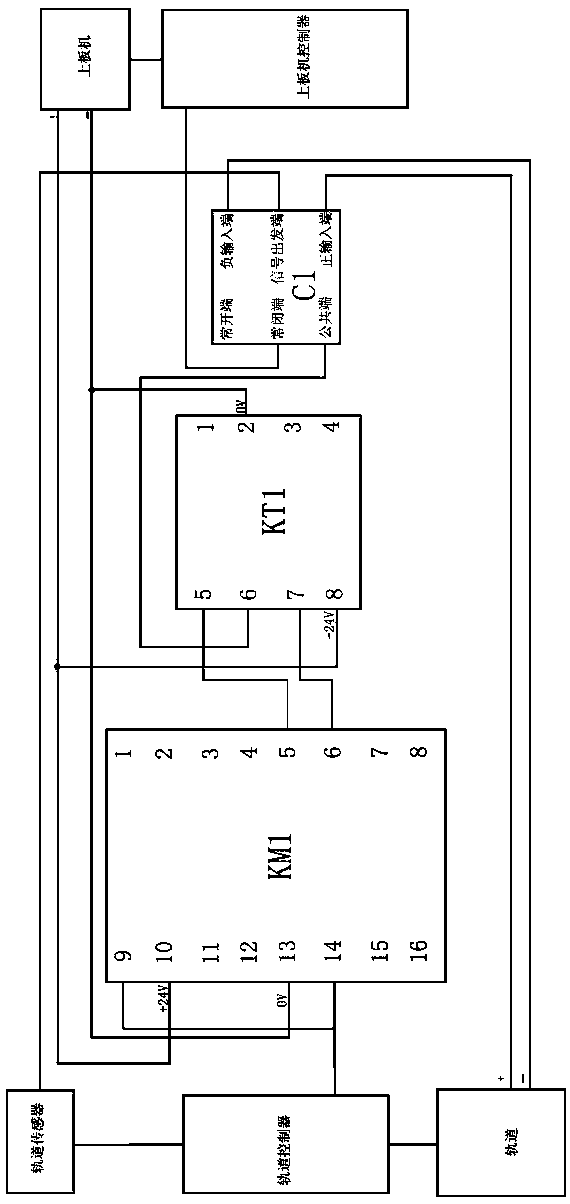

[0019] See figure 1 , a kind of self-locking time-delay circuit of the present invention, comprises relay KM1 and time relay KT1, and relay KM1 and time relay KT1 form self-locking time-delay circuit, 14 ports of relay KM1 connect external input terminal, 10 ports and 13 ports of relay KM1 The ports are respectively connected to the positive and negative poles of the 24V power supply. Port 9 of the relay KM1 is also connected to port 14 of the relay KM1. Port 6 of the relay KM1 is connected to port 7 of the time relay KT1. Port 5 of the relay KM1 is connected to port 5 of the time relay KT1. , the 2 ports and 8 ports of the time relay KT1 are respectively connected to the positive and negative poles of the 24V power supply, and the 6 ports of the time relay KT1 are connected to the external output terminal. This self-locking delay circuit can realize the delayed tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com