Multi-objective multi-constraint combustion optimization method of industrial gas boiler

An industrial gas and combustion optimization technology, applied in the field of boilers, can solve the problems of carbon deposition, poor flame fullness, affecting the effective utilization of the heating surface, etc., to achieve low-pollution operation and improve the matching degree.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the above objects, features and advantages of the present invention more obvious and easy to understand, the specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings, so that the above and other objects, features and advantages of the present invention will be more clear. The same reference numerals refer to the same parts throughout the drawings. The drawings are not intentionally drawn to scale, emphasis instead being placed upon illustrating the subject matter of the invention.

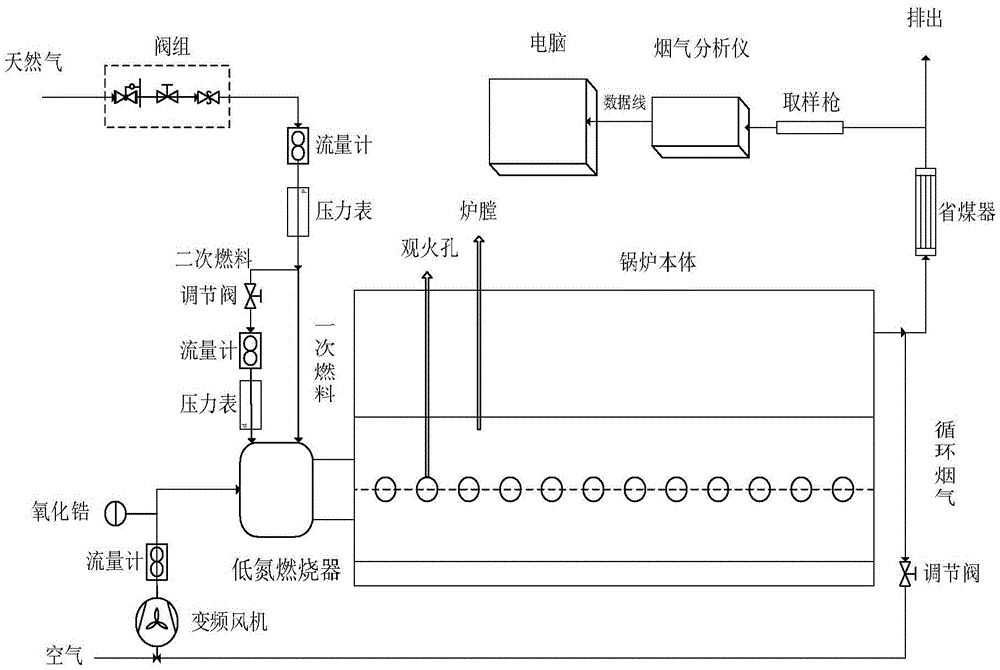

[0021] figure 1 It is a schematic structural diagram of the industrial gas boiler system of the present invention, which adopts a low-nitrogen burner, and the low-nitrogen technology is fuel grading and flue gas recirculation. The system consists of the following parts: 1. Fuel system: the fuel is natural gas, the gas enters the primary fuel pipeline and the secondary fuel pipeline from the main pipeline thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com