Hub and wheel rim reduction gear assembly

A technology of wheel speed reducer and speed reducer, which is applied in the direction of gear transmission, belt/chain/gear, transmission parts, etc. It can solve the problems that the wheel speed ratio cannot be further reduced, maintenance is inconvenient, and the structure is complicated, etc., to achieve The effect of light weight, convenient maintenance and expanding the range of speed ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

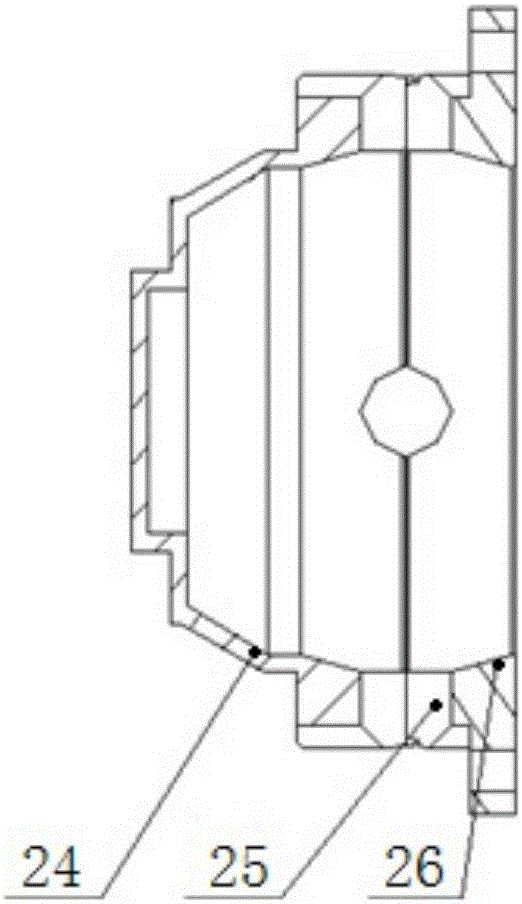

[0038] The inner bevel gear 20 has 17 teeth, the outer bevel gear 15 has 13 teeth, and the conical planetary gear 11 has 9 teeth. 1 is 77.14°, and the shaft angle ∑ of the inner bevel gear 20 and the conical planetary gear 11 2 is 102.86°, thus guaranteeing that ∑ 1 +∑ 2 =180°, the speed ratio of the wheel reducer can be realized as: i=Z 2 / Z 3 +1=17 / 13+1=2.31.

[0039] The present invention adopts a planetary bevel gear reducer. Compared with the prior art, the present invention can realize a wheel speed ratio between 2-2.7, thereby expanding the speed ratio range of the wheel reducer, and the structure is simplified and the weight is light. , When repairing the reducer, it is not necessary to remove the brake drum and other parts, which is convenient for maintenance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com