Gas flow adjusting valve

A gas flow and valve adjustment technology, which is applied in the direction of sliding valves, valve details, valve devices, etc., can solve problems such as insufficient nozzle flow stability, gas flow adjustment lag, and gas flow changes, etc., to prolong service life and ensure stable performance , Enhance the effect of sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

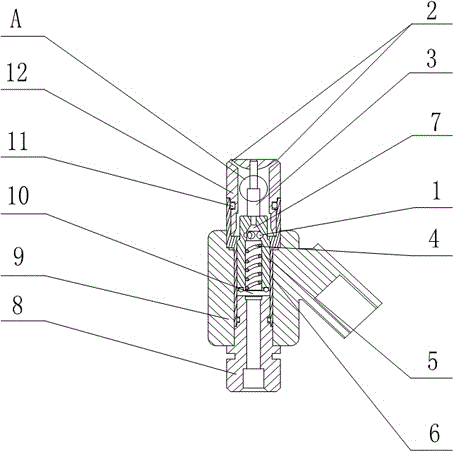

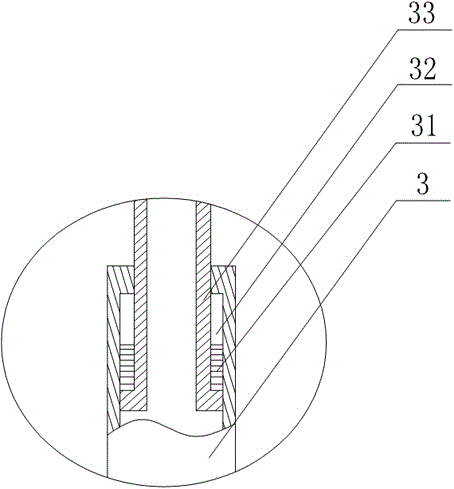

[0022] like figure 1 and figure 2 As shown, the present embodiment includes an electromagnetic valve seat 9 provided with an electromagnetic coil on the inner wall, and a movable valve body 5 and a housing 6 are sequentially arranged in the electromagnetic valve seat 9 from the inside to the outside, and the upper end of the housing 6 faces outward. Extended, and the lower end of the housing 6 is provided with an internal hollow connecting piece 8, there is a gap between the upper end of the connecting piece 8 and the lower end of the movable valve body 5, and the valve nozzle 12 is screwed on the extension end of the housing 6, so The inside of the movable valve body 5 has an air passage 7 communicating with the middle part of the connecting piece 8, the spring 4 is arranged in the air passage 7, and two passages communicating with the air passage 7 are opened on the side wall of the movable valve body 5. The hole 1, the upper end of the movable valve body 5 communicates wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com