A drilling tool and its drilling method

A drilling tool and drilling technology, which is applied to drilling equipment, wellbore/well components, drilling with liquid/gas jets, etc., can solve problems such as drag pressure in extended-reach wells, and achieve large-displacement circular well washing, The effect of increasing the drilling pressure, increasing the water power and the impact force of the pulsed cavitation jet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

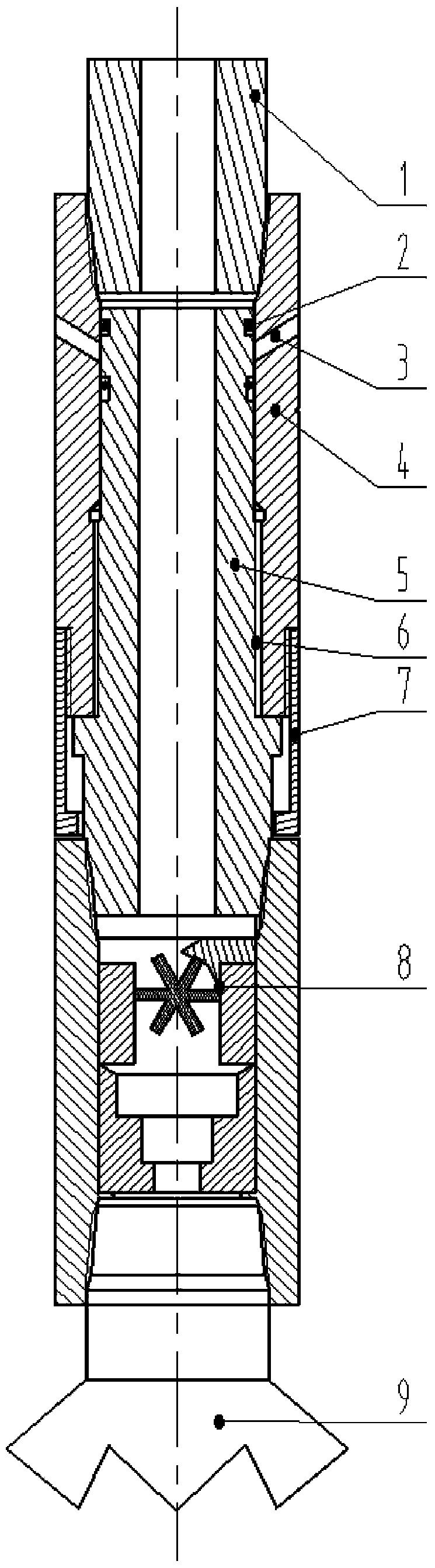

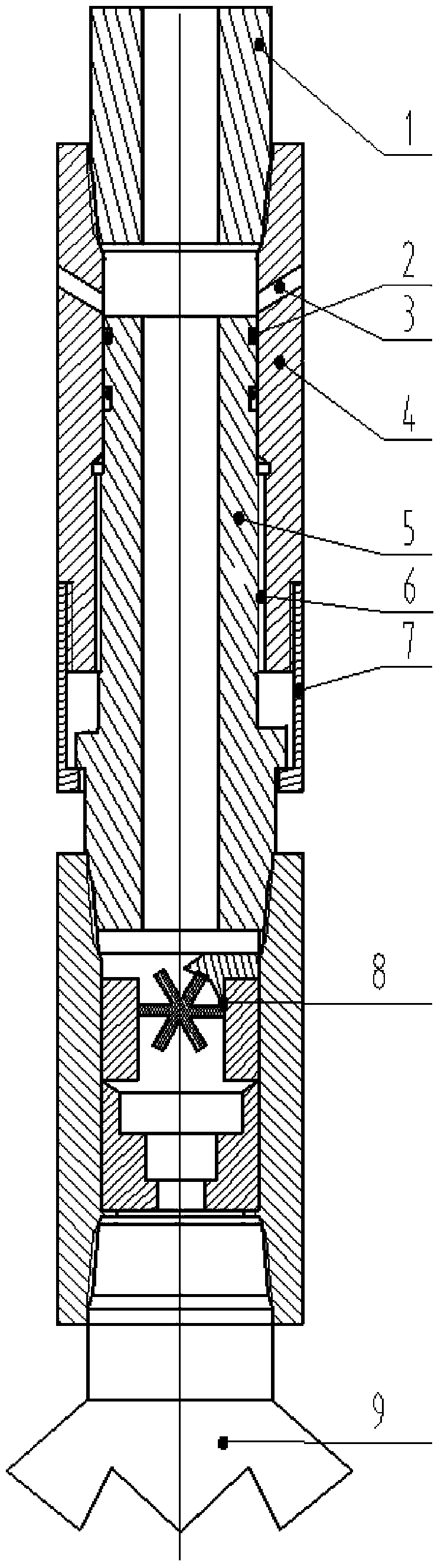

[0014] Attached below figure 1 , attached figure 2 The present invention is further described:

[0015] attached figure 1 And attached figure 2 Among them, a drilling tool includes a spline outer cylinder 4, a spline mandrel 5, an anti-drop cylinder 7, a pulse generator 8, and a drill bit 9. The spline outer cylinder 4 has a cylindrical structure, the upper end and the lower end are respectively processed with threads, and the inside is processed with an internal spline, and a bypass channel 3 passing through the wall of the spline outer cylinder 4 is processed between the internal spline and the upper end thread; The anti-falling cylinder 7 has a cylindrical structure, the upper end is processed with threads, and the lower end has a step protruding toward the inside of the anti-falling cylinder 7; the spline mandrel 5 is externally processed with external splines, and the lower part is processed with threads to connect with the pulse generator 8. There is an outer conve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com