Prefabricated track plate structure capable of absorbing wheel track noise

A prefabricated board and prefabricated technology, applied in tracks, roads, ballast layers, etc., can solve the problems of reduced passenger comfort and increased noise, and achieve the effects of simplifying the process, facilitating drainage, and making production simple.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

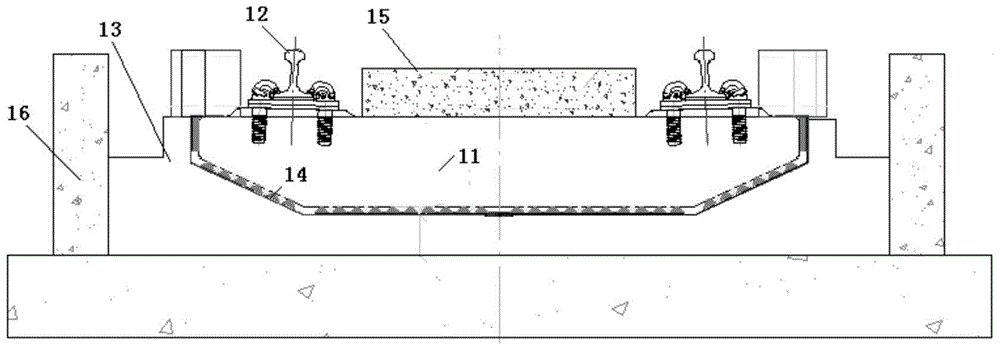

[0020] see figure 1 , showing the prefabricated track slab structure of the present invention with absorbing wheel-rail noise.

[0021] The prefabricated track slab structure with absorbing wheel-rail noise comprises a prefabricated slab 11, the structure and shape of the prefabricated slab 11 can be of a conventional type, the upper surface of the prefabricated slab 11 is provided with a steel rail 12, and the prefabricated slab 11 11 is integrally arranged in a groove of a base 13 , and a vibration damping pad 14 is provided between the prefabricated plate 11 and the groove of the base 13 .

[0022] Vibration between the prefabricated slab 11 and the abutment is eliminated comprehensively through the setting of the vibration damping pad 14. Optionally, the vibration damping pad 14 is located in the middle of the interval between the groove and the prefabricated slab 11, The two ends of the interval are provided with sealing devices to avoid the entry of external rainwater o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com