Steel quenching device

A quenching device, steel technology, applied in the direction of quenching device, heat treatment equipment, furnace, etc., can solve problems such as increasing production cost, multi-manpower, etc., and achieve the effect of fast work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

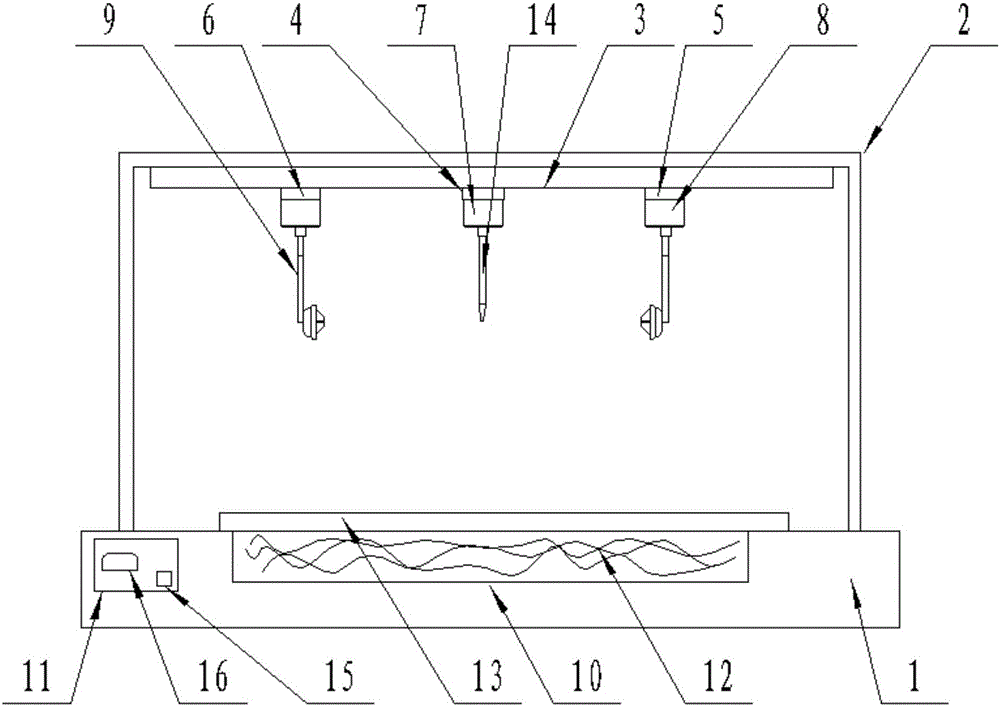

[0012] The present invention is specifically described below in conjunction with accompanying drawing, as figure 1 As shown, a steel quenching device includes a workbench (1), the workbench (1) is provided with a gantry (2), and the beam of the gantry (2) is provided with a slide rail (3) , the slide rail is provided with an electric slider (4), an electric slider A (5) and an electric slider B (6), and the electric slider (4) is located between the electric slider A (5) and the electric slider Between the blocks B (6), the lower surface of the electric slider (4) is provided with a linear cylinder A (7), and the lower surfaces of the electric slider A (5) and the electric slider B (6) are provided with a straight line Cylinder (8), described linear cylinder (8) is provided with manipulator (9), and described workbench (1) upper surface has extraction tank (10), and described workbench (1) side is provided with control device (11), the controller (11) is electrically connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com