Method of synthesizing p-tert-butyl toluene with caprolactam ionic liquid as catalyst

A technology of p-tert-butyltoluene and ionic liquids, applied in catalysts, carbon compound catalysts, chemical instruments and methods, etc., can solve the problems of high synthesis cost of ionic liquids, difficulty in industrial production, toxicity of synthetic raw materials, etc., and achieve easy industrialization. Implementation, high product yield, the effect of omitting the alkaline washing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] In a 100L reactor, vacuumize and fill with nitrogen, add 50kg of toluene, 7.5kg of isobutylene and 7.5kg of [CP]HSO 4 The ionic liquid catalyst was stirred and reacted at 45° C. for 1 hour, and the mixture was allowed to stand and separate after the reaction. After the supernatant was rectified, 19.2kg of p-tert-butyltoluene was obtained. The ionic liquid catalyst in the lower layer can be recycled after being centrifuged, washed with toluene and vacuum-dried, and the recovery rate can reach 99.6%. After repeated use for 10 times, the yield of tert-butyltoluene has no obvious decrease.

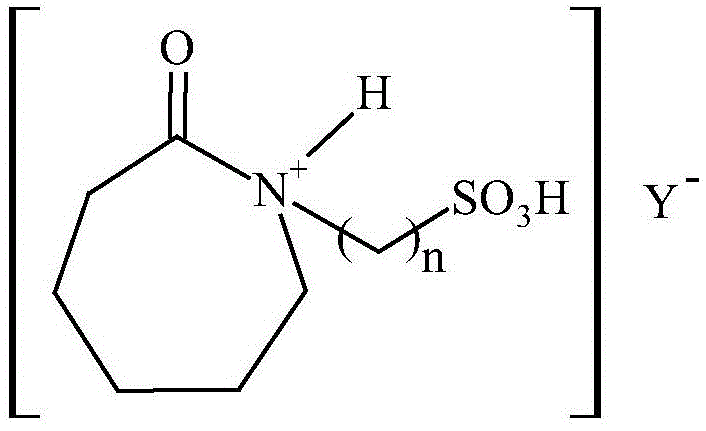

[0030] [CP]HSO in this embodiment 4 (caprolactam hydrogen sulfate) the chemical structural formula of ionic liquid catalyst is:

[0031]

Embodiment 2

[0033] In a 100L reactor, vacuumize and fill with nitrogen protection, add 50kg of toluene, 8kg of isobutylene and 8kg of [CP]pTSA ionic liquid catalyst, stir and react at 35°C for 2.5 hours, after the reaction, let stand and separate. After the supernatant was rectified, 18.8kg of p-tert-butyltoluene was obtained. The ionic liquid catalyst in the lower layer can be recycled after being washed with toluene and vacuum-dried, and the recovery rate can reach 99.8%. After repeated use for 10 times, the yield of tert-butyl toluene has no obvious decrease.

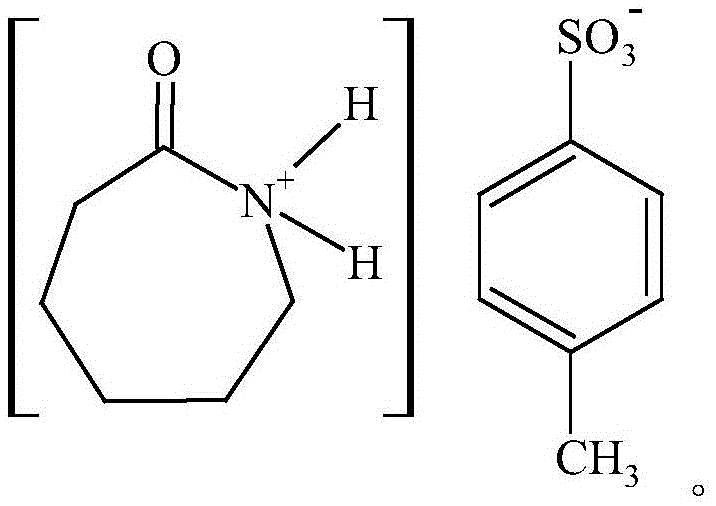

[0034] The chemical structural formula of [CP]pTSA (caprolactam p-toluenesulfonate) ionic liquid catalyst in the present embodiment is:

[0035]

Embodiment 3

[0037] In a 100L reactor, evacuated and filled with nitrogen, add 50kg of toluene, 7.5kg of isobutylene and 8.5kg of [CP]MSA ionic liquid catalyst, stir and react at 40°C for 2 hours, and let stand to separate after the reaction. After the supernatant was rectified, 18.0 kg of p-tert-butyltoluene was obtained. The ionic liquid catalyst in the lower layer can be recycled after being washed with toluene and vacuum-dried, and the recovery rate can reach 99.8%. After repeated use for 10 times, the yield of tert-butyl toluene has no obvious decrease.

[0038] The chemical structural formula of [CP]MSA (caprolactam mesylate) ionic liquid catalyst in the present embodiment is:

[0039]

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com