A cycle feeding mechanism of a printing machine

A technology of feeding mechanism and printing machine, applied in thin material handling, transportation and packaging, object supply and other directions, can solve the problems of high production cost, increase the cost of enterprise land and workshop, and large floor space, so as to reduce the waiting time of workers, The effect of reducing the floor space and saving land costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with accompanying drawing:

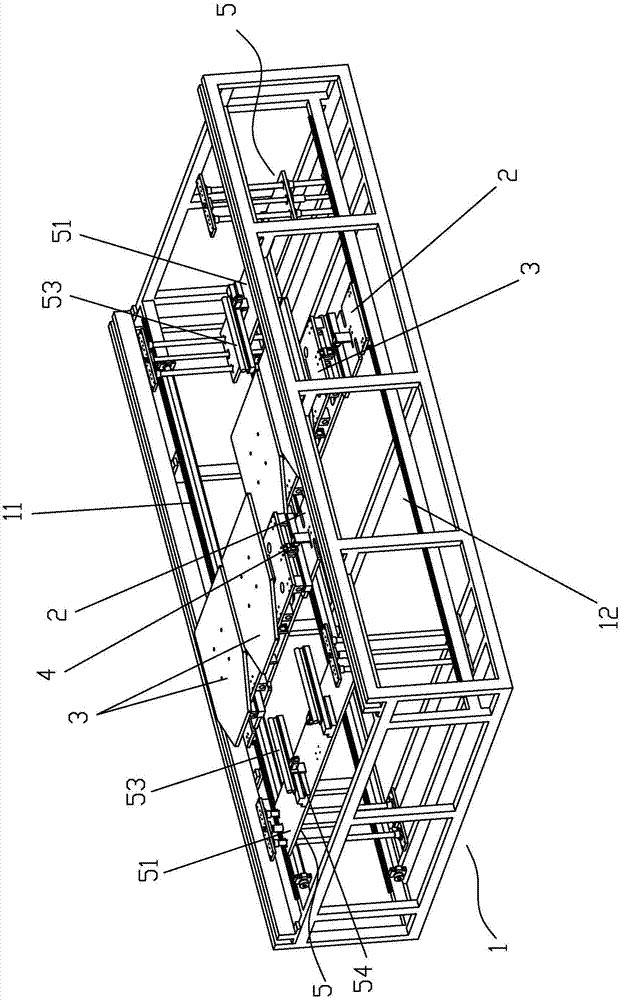

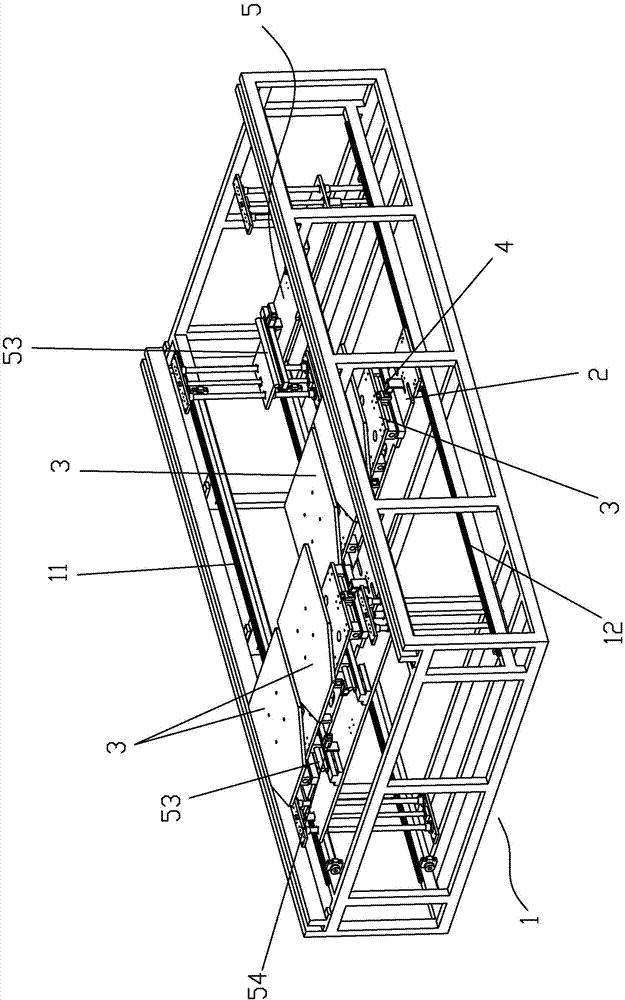

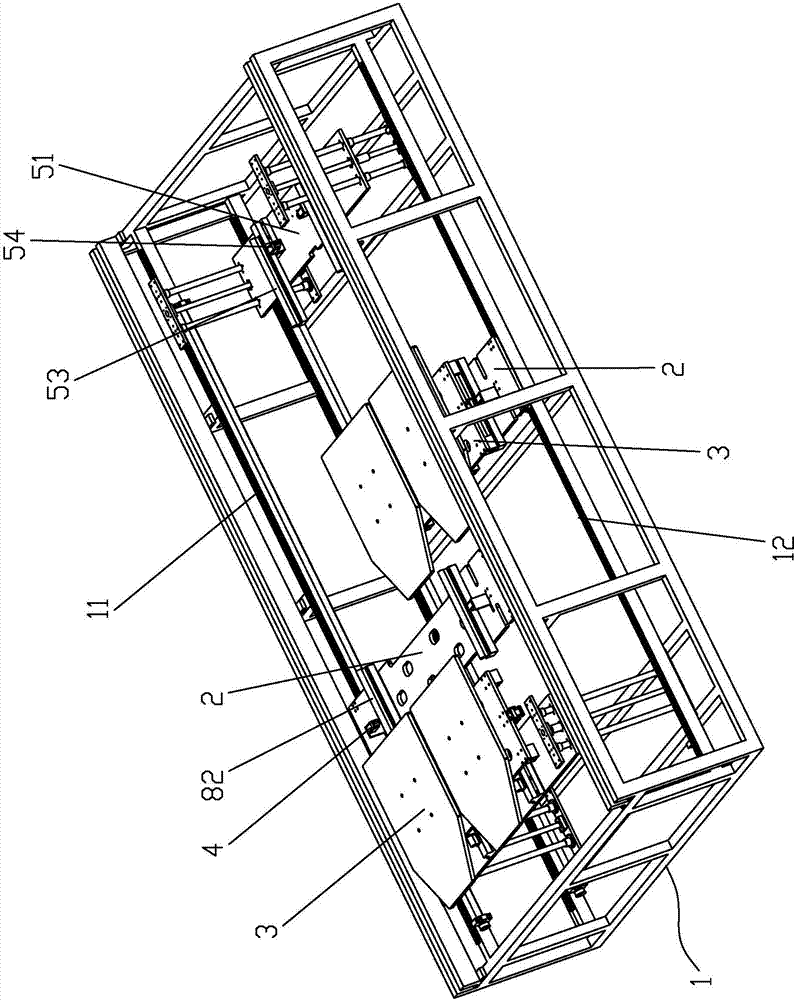

[0027] like Figure 1 to Figure 5 As shown, a circulation feeding mechanism of a printing press includes a frame 1, and the frame 1 includes an upper layer 11 and a lower layer 12 of the frame, and the upper layer 11 of the frame and the lower layer 12 of the frame are respectively provided with A transmission platen 2 that can move back and forth relative to the frame 1. The transmission platen 2 is provided with a movable printing platen 3 that can slide back and forth relative to it and is used to carry printing media. The movable printing platen 3 is connected to the transmission platen. A locking device 4 that can lock the two is provided between the platens 2, and the frame 1 is located on both sides of the transmission platen 2 and is respectively provided with movable printing plates 3 that can transfer the movable printing platen 3 of the upper layer 11 of the fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com