A flexible double-drive gantry structure

A gantry and flexible technology, applied in the field of bed frames, can solve the problems of increasing the friction force of the guiding mechanism, difficulty in adjusting the verticality, and affecting the life of the guiding mechanism, etc., and achieve the effects of eliminating verticality errors, high structural stability, and eliminating internal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

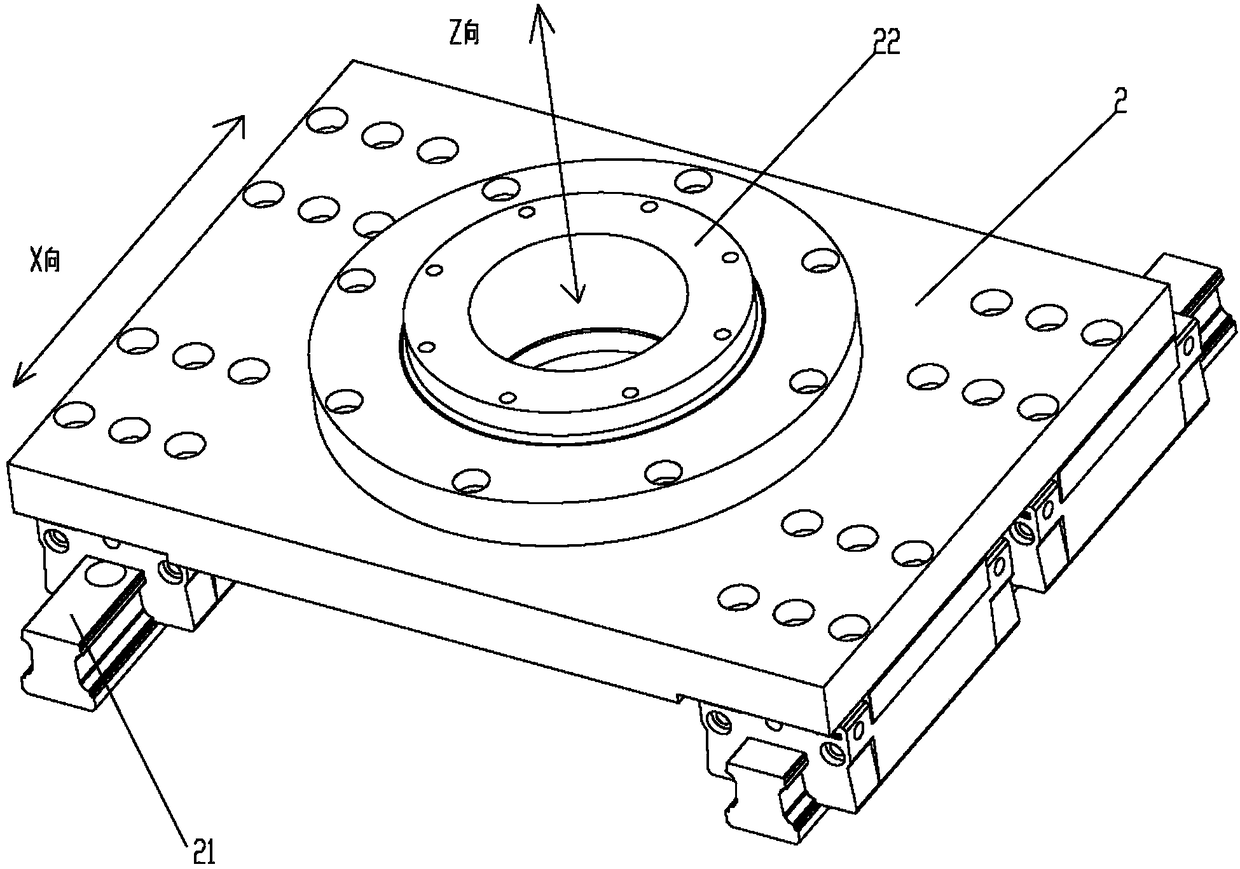

[0020] Please refer to the attached figure 1 to attach Figure 5 As shown, the present invention is a flexible double-drive gantry structure, which is composed of an X-direction beam 1, a support frame I2, a support frame II3, a guide drive assembly I4, a guide drive assembly II5, and a base 6.

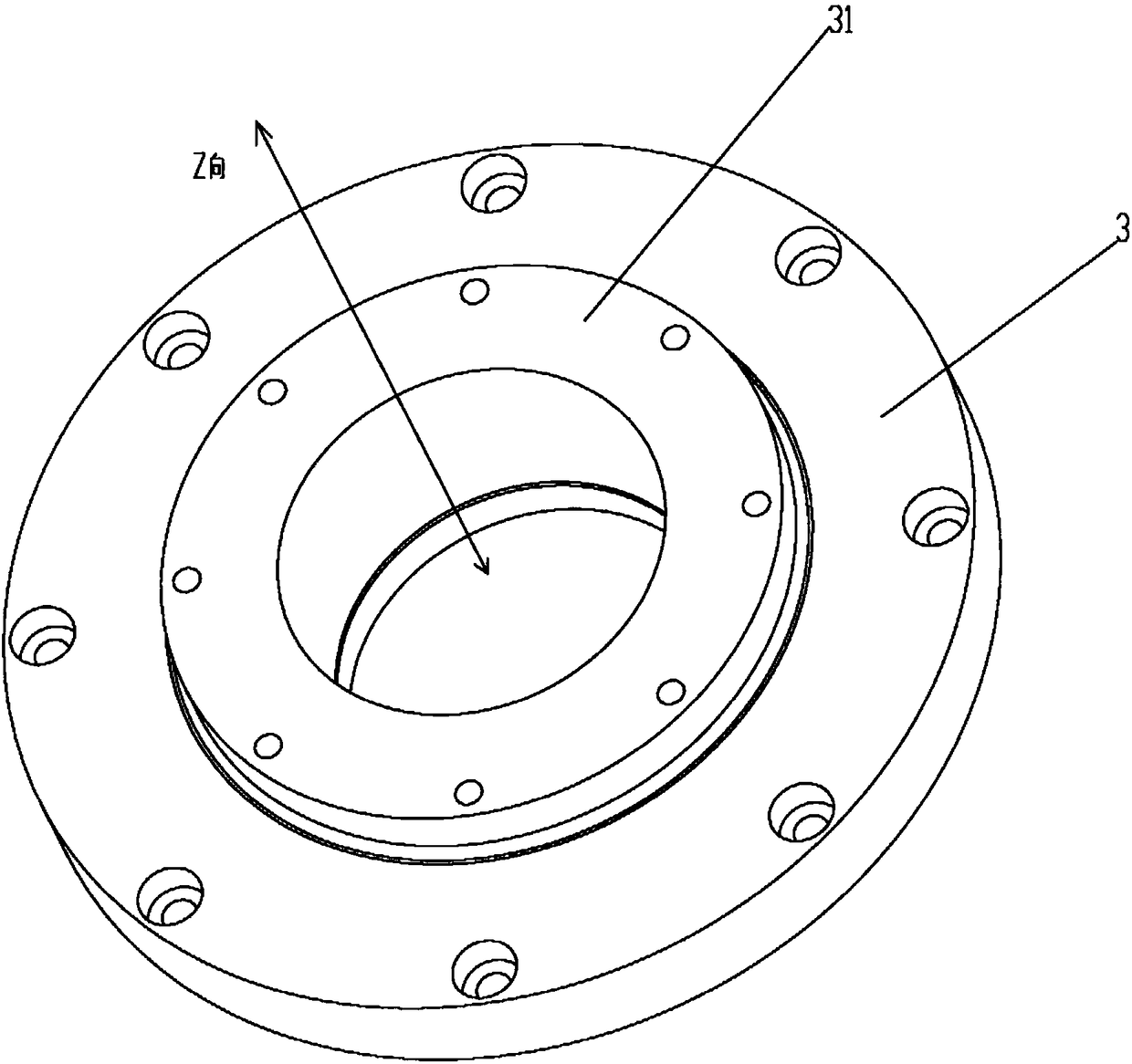

[0021] Wherein, the support frame I2 and the support frame II3 are respectively fixedly installed on the guide drive assembly I4 and the guide drive assembly II5 which are arranged parallel to each other. An X-direction guiding mechanism 21 capable of moving along the X direction and a rotating mechanism I22 capable of rotating along the Z direction are provided on the support frame I2; the rotating mechanism I22 is installed on the X-directing mechanism 21. A rotating mechanism II31 capable of rotating along the Z direction is provided on the support frame II3.

[0022] The X-direction beam 1 is installed on the supporting frame I2 and the supporting frame II arranged parallel to e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com