Method for machining frame of cold continuous rolling mill

A technology of cold tandem rolling mill and processing method, which is applied in the processing field of rolling mill racks, can solve the problems of limited support points, bending deformation, and the parallelism of large surfaces on both sides of racks cannot meet the design requirements, so as to improve the verticality accuracy, The effect of eliminating verticality errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

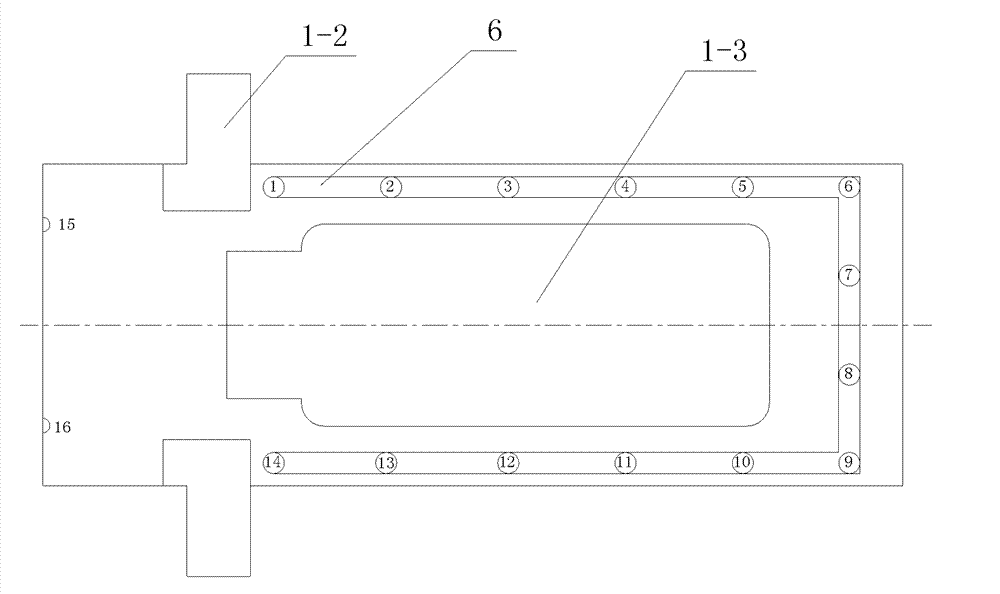

[0021] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

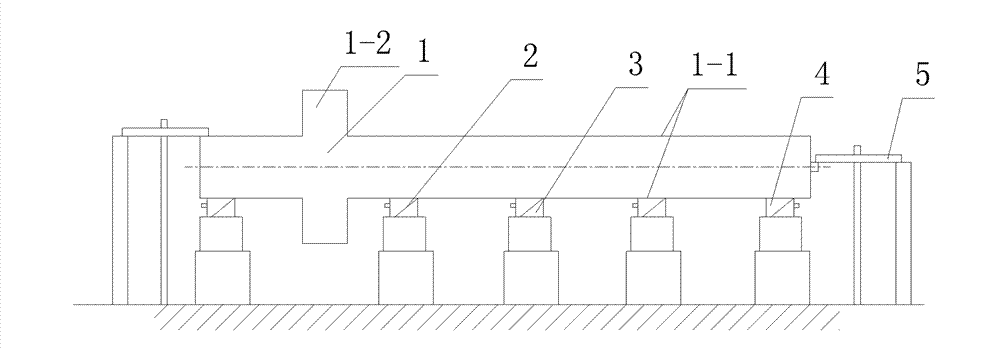

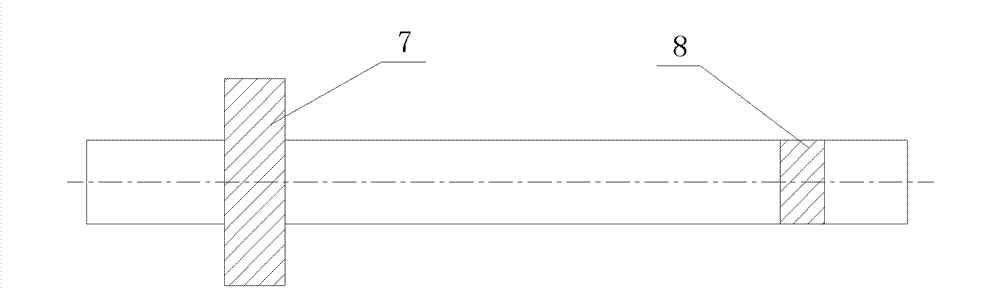

[0022] A kind of processing method of cold tandem rolling mill frame, please refer to Figure 1 to Figure 7 .

[0023] Same as the prior art, after the rough machining, a machining margin of 3-4 mm is left on each dimension of the frame, and then the finish machining is carried out. Proceed as follows:

[0024] Place the large surfaces 1-1 on both sides of the frame 1 on the workbench of the gantry milling machine, support it with adjustable shim irons, and level the upper plane of the frame 1 after being laid flat.

[0025] When clamping the frame 1, firstly let the adjustable pad iron 2 in the middle be stressed,

[0026] Level the upper plane with the dial indicator carried by the machine tool, and the rack will present a bow shape with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com