A kind of plant fiber desiccant and preparation method thereof

A plant fiber and desiccant technology, applied in separation methods, chemical instruments and methods, other chemical processes, etc., can solve the problems of limited adsorption capacity, polluted environment to be dried, and low moisture absorption rate of desiccant, and achieves fast moisture absorption rate. , the effect of high moisture absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

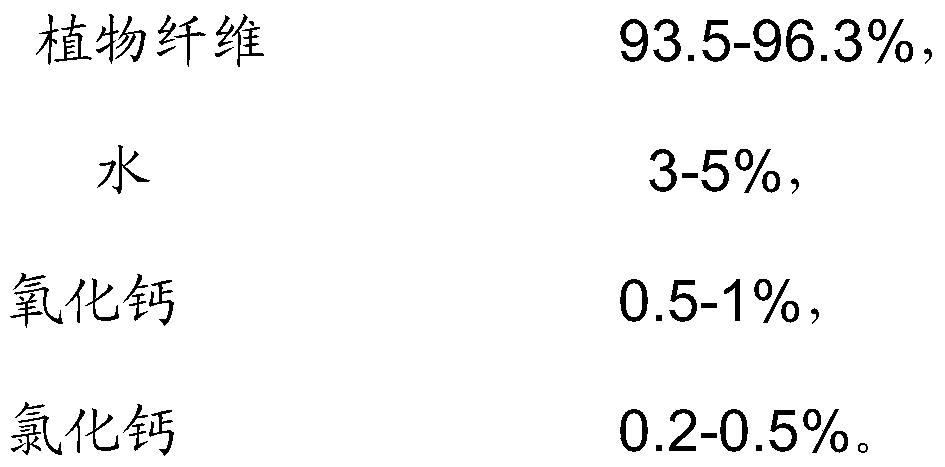

[0022] Embodiment 1 A vegetable fiber desiccant, comprising the following components in 100% by mass:

[0023]

[0024] The preparation method of the plant fiber desiccant comprises the following steps,

[0025] 1), using traditional papermaking technology to process wood raw materials into roll fiber paper;

[0026] 2), by step 1) gained roll fiber paper is cut into sheet fiber paper according to the required size;

[0027] 3), configure the drying liquid, the mass percentage of calcium chloride in the drying liquid is 0.2%, the mass percentage of calcium oxide is 0.5%, and the remainder is water; step 2) The gained flat fiber paper is dipped In the drying liquid, the drying liquid is fully saturated with the flat fiber paper;

[0028] 4), taking out step 3) the sheet fiber paper soaked in the drying solution, placed in an oven and dried to a moisture content of 3% in the sheet fiber paper;

[0029] 5) Packing the flat-sheet fiber paper with a moisture content of 3% obt...

Embodiment 2

[0030] Embodiment 2 A vegetable fiber desiccant, comprising the following components in 100% by mass:

[0031]

[0032] The preparation method of the plant fiber desiccant comprises the following steps,

[0033] 1), using traditional papermaking technology to process wood raw materials into roll fiber paper;

[0034] 2), by step 1) gained roll fiber paper is cut into sheet fiber paper according to the required size;

[0035] 3), configure the drying liquid, the mass percentage of calcium chloride in the drying liquid is 0.2%, the mass percentage of calcium oxide is 0.5%, and the remainder is water; step 2) The gained flat fiber paper is dipped In the drying liquid, the drying liquid is fully saturated with the flat fiber paper;

[0036] 4), taking out step 3) the sheet fiber paper soaked in the drying solution, placed in an oven and dried to a moisture content of 8% in the sheet fiber paper;

[0037] 5), packaging the flat fiber paper with a moisture content of 8% obtain...

Embodiment 3

[0038] Embodiment 3 A vegetable fiber desiccant, comprising the following components in 100% by mass:

[0039]

[0040]

[0041] The preparation method of the plant fiber desiccant comprises the following steps,

[0042] 1), using traditional papermaking technology to process wood raw materials into roll fiber paper;

[0043] 2), by step 1) gained roll fiber paper is cut into sheet fiber paper according to the required size;

[0044] 3), configure the drying liquid, in the drying liquid, the mass percentage of calcium chloride is 0.5%, the mass percentage of calcium oxide is 1%, and the remainder is water; dipping the obtained flat fiber paper in step 2) In the drying liquid, the drying liquid is fully saturated with the flat fiber paper;

[0045] 4), taking out step 3) the sheet fiber paper soaked in the drying solution, placed in an oven and dried to a moisture content of 5% in the sheet fiber paper;

[0046] 5) Packing the flat-sheet fiber paper with a moisture con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com