Methods of making rosin esters

A technology of rosin ester and rosin, which is applied in the field of manufacturing rosin ester and can solve the problems such as rosin ester not having proper performance

Inactive Publication Date: 2016-06-08

ARIZONA CHEM CO

View PDF22 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] Although suitable for many applications, many existing rosin esters do not have suitable properties for specific applications

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0099] general method

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Login to View More

Abstract

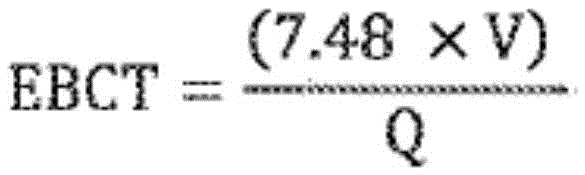

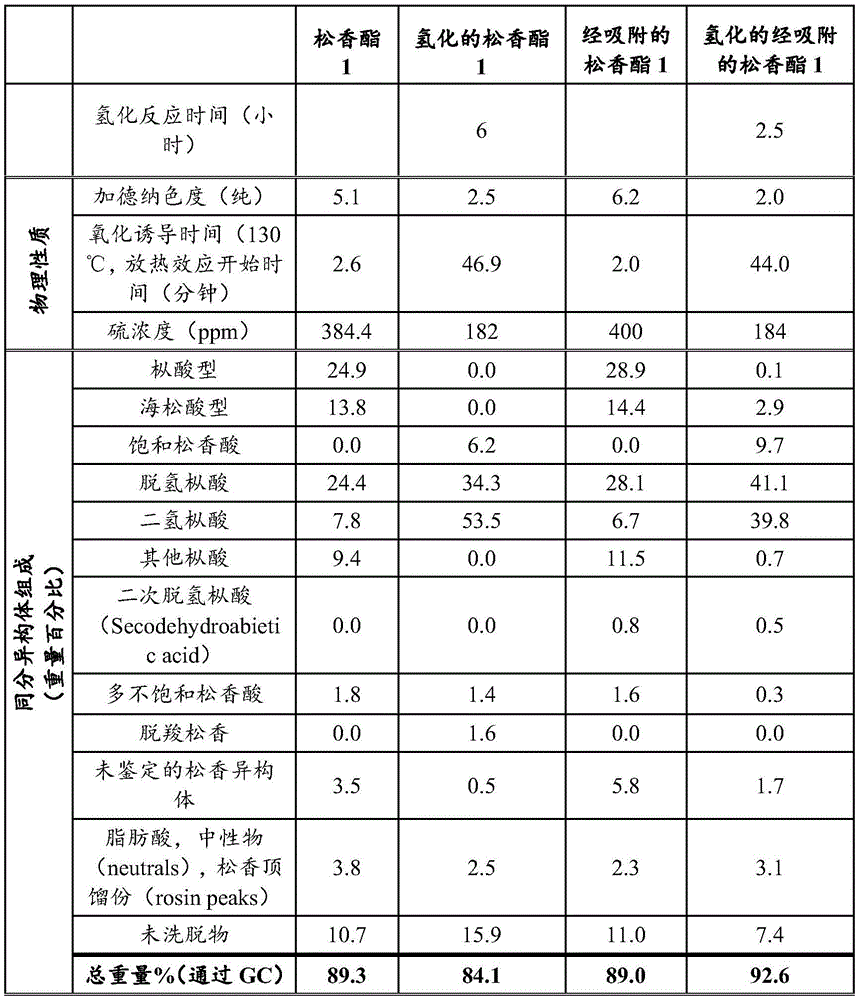

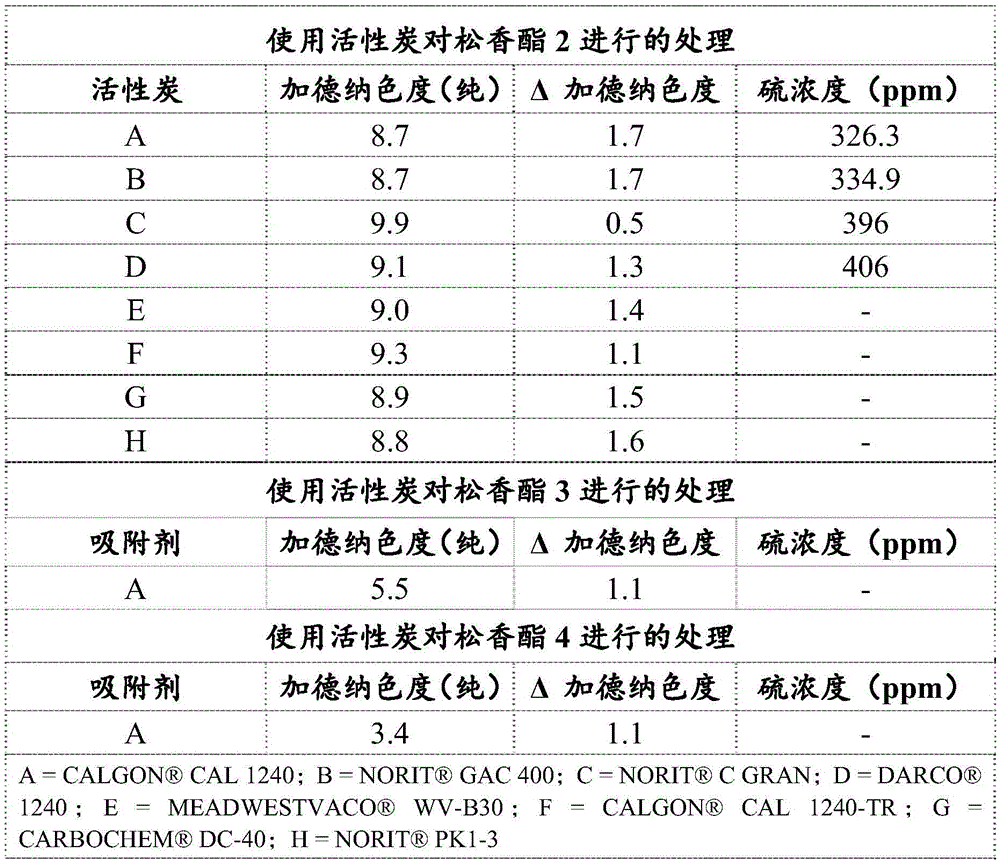

Provided herein are methods of making rosin esters. The methods can involve contacting a rosin ester with a microporous adsorbent. Treatment with a microporous adsorbent, such as an activated carbon, can improve the color of the rosin ester (e.g., reduce the neat Gardner color of the rosin ester by at least 1 Gardner color unit), reduce the concentration of sulfur in the rosin ester (e.g., reduce the concentration of sulfur in the rosin ester by at least 50 ppm), or combinations thereof. Rosin esters prepared by the methods described herein, as well as methods of using thereof, are also described.

Description

technical field [0001] This application is primarily concerned with methods of making rosin esters. Background technique [0002] Rosin esters, including those derived from polyols, have been known for over 50 years (see, eg, US Patent No. 1,820,265 to Bent et al.). Rosin esters are generally derived from rosin (which is primarily an isomeric C 20 tricyclic monocarboxylic acid) with an alcohol such as glycerol or pentaerythritol. The resulting rosin esters are used as additives in a variety of applications including, for example, as tackifiers in hot melt and pressure sensitive adhesives, modifiers for rubber and various plastics, emulsifiers for synthetic rubbers , the base material for chewing gum, resins in coating compositions such as traffic paints and inks, and sizing agents for papermaking. [0003] While suitable for many applications, many existing rosin esters do not possess suitable properties for particular applications. In particular, many commercially avail...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C09F1/04C08L93/04B01D15/00

CPCB01D15/00C08L93/04C09F1/04C09F1/02

Inventor 保罗·A·威廉斯劳埃德·A·纳尔逊雷切尔·C·塞弗伦斯

Owner ARIZONA CHEM CO

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com